Are you a seasoned Metal Numerical Control Programmer seeking a new career path? Discover our professionally built Metal Numerical Control Programmer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

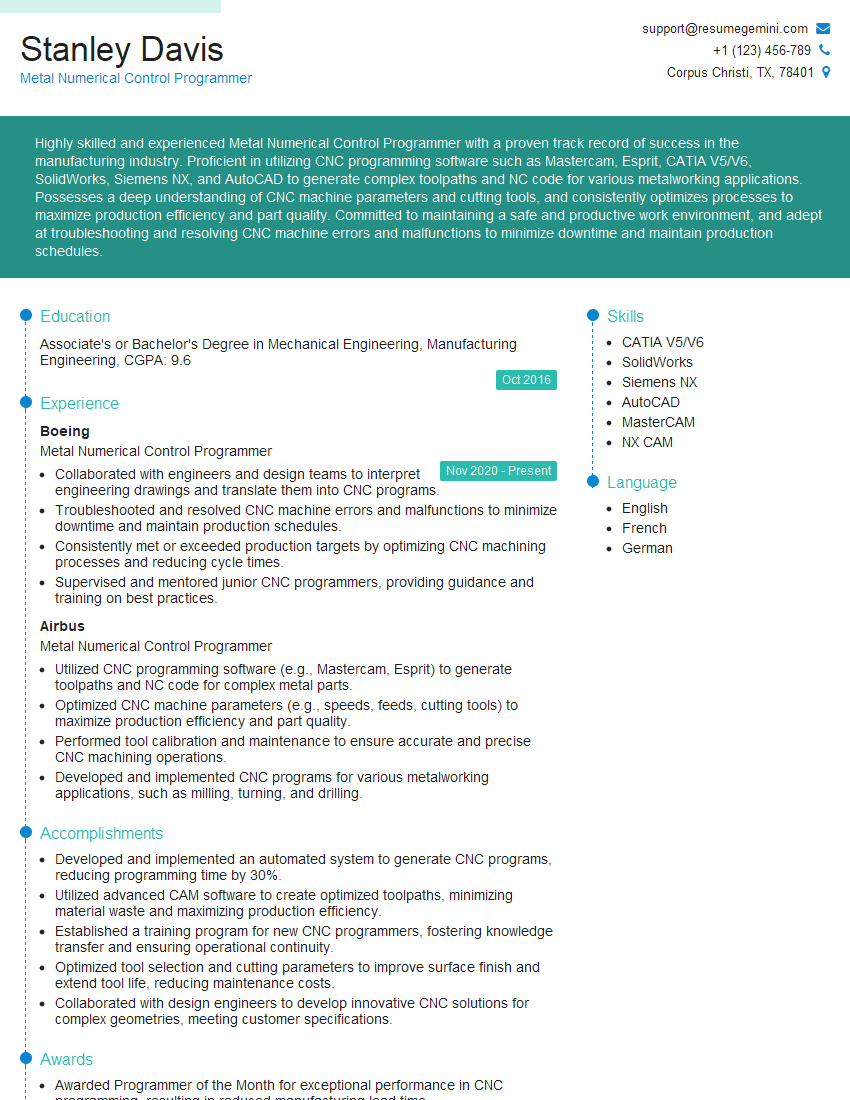

Stanley Davis

Metal Numerical Control Programmer

Summary

Highly skilled and experienced Metal Numerical Control Programmer with a proven track record of success in the manufacturing industry. Proficient in utilizing CNC programming software such as Mastercam, Esprit, CATIA V5/V6, SolidWorks, Siemens NX, and AutoCAD to generate complex toolpaths and NC code for various metalworking applications. Possesses a deep understanding of CNC machine parameters and cutting tools, and consistently optimizes processes to maximize production efficiency and part quality. Committed to maintaining a safe and productive work environment, and adept at troubleshooting and resolving CNC machine errors and malfunctions to minimize downtime and maintain production schedules.

Education

Associate’s or Bachelor’s Degree in Mechanical Engineering, Manufacturing Engineering

October 2016

Skills

- CATIA V5/V6

- SolidWorks

- Siemens NX

- AutoCAD

- MasterCAM

- NX CAM

Work Experience

Metal Numerical Control Programmer

- Collaborated with engineers and design teams to interpret engineering drawings and translate them into CNC programs.

- Troubleshooted and resolved CNC machine errors and malfunctions to minimize downtime and maintain production schedules.

- Consistently met or exceeded production targets by optimizing CNC machining processes and reducing cycle times.

- Supervised and mentored junior CNC programmers, providing guidance and training on best practices.

Metal Numerical Control Programmer

- Utilized CNC programming software (e.g., Mastercam, Esprit) to generate toolpaths and NC code for complex metal parts.

- Optimized CNC machine parameters (e.g., speeds, feeds, cutting tools) to maximize production efficiency and part quality.

- Performed tool calibration and maintenance to ensure accurate and precise CNC machining operations.

- Developed and implemented CNC programs for various metalworking applications, such as milling, turning, and drilling.

Accomplishments

- Developed and implemented an automated system to generate CNC programs, reducing programming time by 30%.

- Utilized advanced CAM software to create optimized toolpaths, minimizing material waste and maximizing production efficiency.

- Established a training program for new CNC programmers, fostering knowledge transfer and ensuring operational continuity.

- Optimized tool selection and cutting parameters to improve surface finish and extend tool life, reducing maintenance costs.

- Collaborated with design engineers to develop innovative CNC solutions for complex geometries, meeting customer specifications.

Awards

- Awarded Programmer of the Month for exceptional performance in CNC programming, resulting in reduced manufacturing lead time.

- Recognized for expertise in Gcode and Mcode programming, contributing to the successful completion of complex projects.

- Received Team Excellence Award for collaboration in developing a new CNC programming methodology that enhanced product quality.

- Honored for proficiency in CNC simulation software, allowing for accurate prediction and mitigation of potential manufacturing issues.

Certificates

- CNC Programming Certification

- CAM Programming Certification

- Geometric Dimensioning and Tolerancing (GD&T) Certification

- Lean Manufacturing Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Metal Numerical Control Programmer

- Showcase your proficiency in CNC programming software by providing specific examples of the tools you’ve used and the results you’ve achieved.

- Quantify your accomplishments whenever possible to demonstrate the impact of your work on production efficiency and part quality.

- Highlight your ability to troubleshoot and resolve CNC machine errors and malfunctions, as this is a critical skill for ensuring smooth production.

- Emphasize your commitment to maintaining a safe and productive work environment, as this is essential in the manufacturing industry.

Essential Experience Highlights for a Strong Metal Numerical Control Programmer Resume

- Utilized CNC programming software (e.g., Mastercam, Esprit) to generate toolpaths and NC code for complex metal parts.

- Optimized CNC machine parameters (e.g., speeds, feeds, cutting tools) to maximize production efficiency and part quality.

- Supervised and mentored junior CNC programmers, providing guidance and training on best practices.

- Performed tool calibration and maintenance to ensure accurate and precise CNC machining operations.

- Troubleshooted and resolved CNC machine errors and malfunctions to minimize downtime and maintain production schedules.

- Collaborated with engineers and design teams to interpret engineering drawings and translate them into CNC programs.

- Developed and implemented CNC programs for various metalworking applications, such as milling, turning, and drilling.

Frequently Asked Questions (FAQ’s) For Metal Numerical Control Programmer

What is the role of a Metal Numerical Control Programmer?

A Metal Numerical Control Programmer is responsible for generating toolpaths and NC code for complex metal parts using CNC programming software. They optimize CNC machine parameters to maximize production efficiency and part quality, and troubleshoot and resolve CNC machine errors and malfunctions to minimize downtime. They also collaborate with engineers and design teams to interpret engineering drawings and translate them into CNC programs.

What skills are required to be a successful Metal Numerical Control Programmer?

Successful Metal Numerical Control Programmers typically have a strong understanding of CNC programming software, CNC machine parameters, and cutting tools. They are also proficient in troubleshooting and resolving CNC machine errors and malfunctions, and have a commitment to maintaining a safe and productive work environment.

What is the job outlook for Metal Numerical Control Programmers?

The job outlook for Metal Numerical Control Programmers is expected to be good in the coming years, as the manufacturing industry continues to grow and adopt new technologies.

What is the salary range for Metal Numerical Control Programmers?

The salary range for Metal Numerical Control Programmers can vary depending on experience, location, and employer. However, according to the U.S. Bureau of Labor Statistics, the median annual salary for Computer Numerical Control (CNC) Programmers was $56,200 in May 2021.

What are the career advancement opportunities for Metal Numerical Control Programmers?

Metal Numerical Control Programmers can advance their careers by becoming CNC supervisors, CNC managers, or CNC engineers. They can also specialize in a particular area of CNC programming, such as mold making or aerospace manufacturing.