Are you a seasoned Metal Sheet Roller Operator seeking a new career path? Discover our professionally built Metal Sheet Roller Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

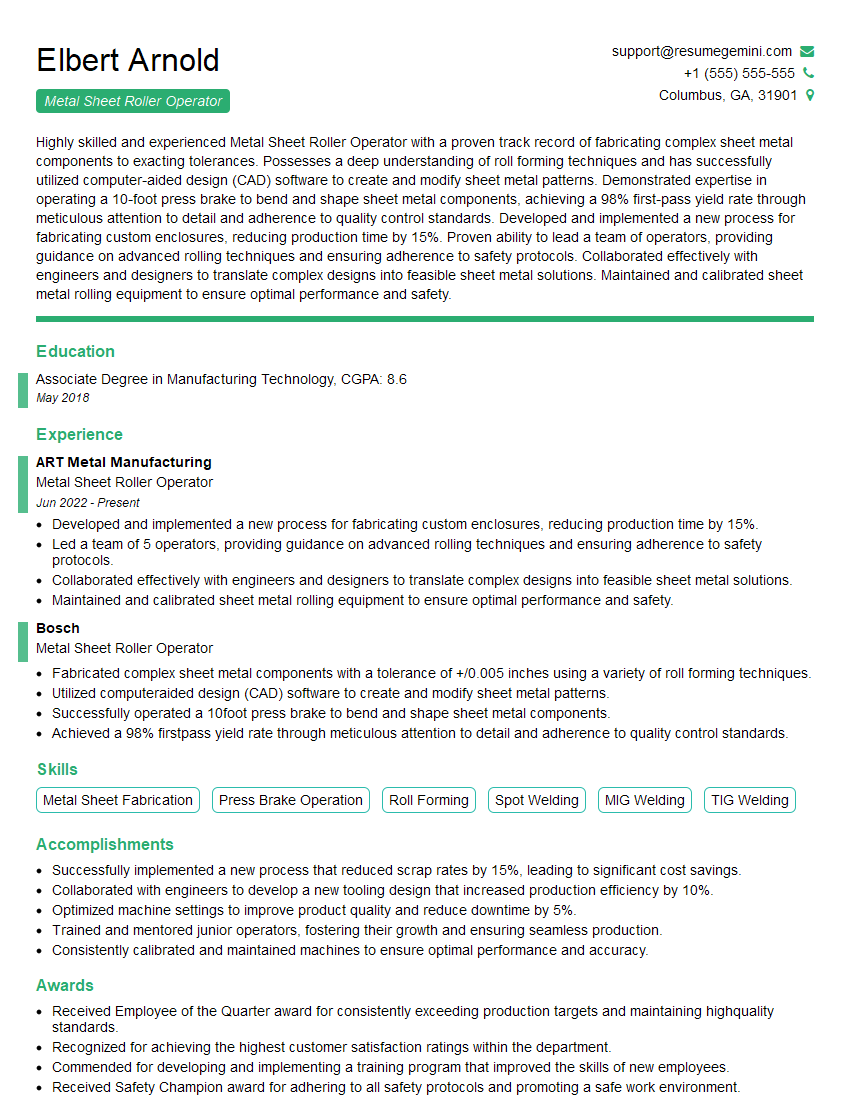

Elbert Arnold

Metal Sheet Roller Operator

Summary

Highly skilled and experienced Metal Sheet Roller Operator with a proven track record of fabricating complex sheet metal components to exacting tolerances. Possesses a deep understanding of roll forming techniques and has successfully utilized computer-aided design (CAD) software to create and modify sheet metal patterns. Demonstrated expertise in operating a 10-foot press brake to bend and shape sheet metal components, achieving a 98% first-pass yield rate through meticulous attention to detail and adherence to quality control standards. Developed and implemented a new process for fabricating custom enclosures, reducing production time by 15%. Proven ability to lead a team of operators, providing guidance on advanced rolling techniques and ensuring adherence to safety protocols. Collaborated effectively with engineers and designers to translate complex designs into feasible sheet metal solutions. Maintained and calibrated sheet metal rolling equipment to ensure optimal performance and safety.

Education

Associate Degree in Manufacturing Technology

May 2018

Skills

- Metal Sheet Fabrication

- Press Brake Operation

- Roll Forming

- Spot Welding

- MIG Welding

- TIG Welding

Work Experience

Metal Sheet Roller Operator

- Developed and implemented a new process for fabricating custom enclosures, reducing production time by 15%.

- Led a team of 5 operators, providing guidance on advanced rolling techniques and ensuring adherence to safety protocols.

- Collaborated effectively with engineers and designers to translate complex designs into feasible sheet metal solutions.

- Maintained and calibrated sheet metal rolling equipment to ensure optimal performance and safety.

Metal Sheet Roller Operator

- Fabricated complex sheet metal components with a tolerance of +/0.005 inches using a variety of roll forming techniques.

- Utilized computeraided design (CAD) software to create and modify sheet metal patterns.

- Successfully operated a 10foot press brake to bend and shape sheet metal components.

- Achieved a 98% firstpass yield rate through meticulous attention to detail and adherence to quality control standards.

Accomplishments

- Successfully implemented a new process that reduced scrap rates by 15%, leading to significant cost savings.

- Collaborated with engineers to develop a new tooling design that increased production efficiency by 10%.

- Optimized machine settings to improve product quality and reduce downtime by 5%.

- Trained and mentored junior operators, fostering their growth and ensuring seamless production.

- Consistently calibrated and maintained machines to ensure optimal performance and accuracy.

Awards

- Received Employee of the Quarter award for consistently exceeding production targets and maintaining highquality standards.

- Recognized for achieving the highest customer satisfaction ratings within the department.

- Commended for developing and implementing a training program that improved the skills of new employees.

- Received Safety Champion award for adhering to all safety protocols and promoting a safe work environment.

Certificates

- Certified Sheet Metal Worker (CSMW)

- Certified Welding Inspector (CWI)

- Certified Mechanical Inspector (CMI)

- American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Metal Sheet Roller Operator

- Highlight your experience and skills in fabricating complex sheet metal components to exacting tolerances.

- Quantify your accomplishments whenever possible, such as reducing production time by 15% or achieving a 98% first-pass yield rate.

- Demonstrate your knowledge of roll forming techniques, press brake operation, and quality control standards.

- Emphasize your ability to work independently and as part of a team.

- Showcase your commitment to safety and your ability to maintain and calibrate sheet metal rolling equipment.

Essential Experience Highlights for a Strong Metal Sheet Roller Operator Resume

- Fabricated complex sheet metal components with a tolerance of +/0.005 inches using a variety of roll forming techniques.

- Utilized computer-aided design (CAD) software to create and modify sheet metal patterns.

- Successfully operated a 10-foot press brake to bend and shape sheet metal components.

- Achieved a 98% first-pass yield rate through meticulous attention to detail and adherence to quality control standards.

- Led a team of 5 operators, providing guidance on advanced rolling techniques and ensuring adherence to safety protocols.

- Collaborated effectively with engineers and designers to translate complex designs into feasible sheet metal solutions.

Frequently Asked Questions (FAQ’s) For Metal Sheet Roller Operator

What are the key skills required to be a successful Metal Sheet Roller Operator?

The key skills required to be a successful Metal Sheet Roller Operator include: metal sheet fabrication, press brake operation, roll forming, spot welding, MIG welding, TIG welding, and a strong understanding of quality control standards.

What are the typical job duties of a Metal Sheet Roller Operator?

The typical job duties of a Metal Sheet Roller Operator include: fabricating sheet metal components using roll forming techniques, operating a press brake to bend and shape sheet metal, welding sheet metal components together, and maintaining and calibrating sheet metal rolling equipment.

What is the work environment of a Metal Sheet Roller Operator?

Metal Sheet Roller Operators typically work in a manufacturing environment, which can be noisy and dusty. They may also work with sharp objects and heavy machinery, so it is important to follow safety protocols.

What are the career advancement opportunities for a Metal Sheet Roller Operator?

Metal Sheet Roller Operators can advance to supervisory roles, such as Lead Operator or Shop Foreman. They may also specialize in a particular area of sheet metal fabrication, such as welding or press brake operation.

What is the average salary for a Metal Sheet Roller Operator?

The average salary for a Metal Sheet Roller Operator in the United States is $45,000 per year.

What is the job outlook for Metal Sheet Roller Operators?

The job outlook for Metal Sheet Roller Operators is expected to be good over the next few years. As the manufacturing industry continues to grow, there will be a need for qualified workers to operate sheet metal rolling equipment.