Are you a seasoned Metalizer Operator seeking a new career path? Discover our professionally built Metalizer Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

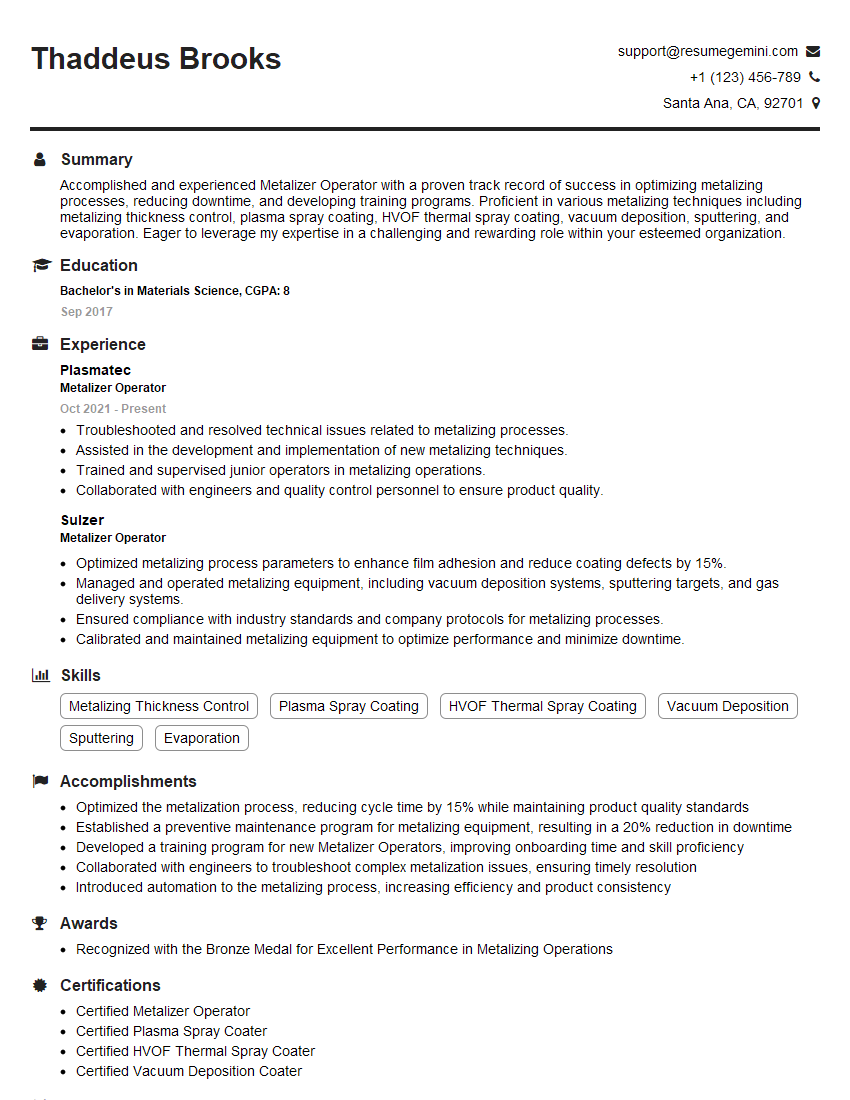

Thaddeus Brooks

Metalizer Operator

Summary

Accomplished and experienced Metalizer Operator with a proven track record of success in optimizing metalizing processes, reducing downtime, and developing training programs. Proficient in various metalizing techniques including metalizing thickness control, plasma spray coating, HVOF thermal spray coating, vacuum deposition, sputtering, and evaporation. Eager to leverage my expertise in a challenging and rewarding role within your esteemed organization.

Education

Bachelor’s in Materials Science

September 2017

Skills

- Metalizing Thickness Control

- Plasma Spray Coating

- HVOF Thermal Spray Coating

- Vacuum Deposition

- Sputtering

- Evaporation

Work Experience

Metalizer Operator

- Troubleshooted and resolved technical issues related to metalizing processes.

- Assisted in the development and implementation of new metalizing techniques.

- Trained and supervised junior operators in metalizing operations.

- Collaborated with engineers and quality control personnel to ensure product quality.

Metalizer Operator

- Optimized metalizing process parameters to enhance film adhesion and reduce coating defects by 15%.

- Managed and operated metalizing equipment, including vacuum deposition systems, sputtering targets, and gas delivery systems.

- Ensured compliance with industry standards and company protocols for metalizing processes.

- Calibrated and maintained metalizing equipment to optimize performance and minimize downtime.

Accomplishments

- Optimized the metalization process, reducing cycle time by 15% while maintaining product quality standards

- Established a preventive maintenance program for metalizing equipment, resulting in a 20% reduction in downtime

- Developed a training program for new Metalizer Operators, improving onboarding time and skill proficiency

- Collaborated with engineers to troubleshoot complex metalization issues, ensuring timely resolution

- Introduced automation to the metalizing process, increasing efficiency and product consistency

Awards

- Recognized with the Bronze Medal for Excellent Performance in Metalizing Operations

Certificates

- Certified Metalizer Operator

- Certified Plasma Spray Coater

- Certified HVOF Thermal Spray Coater

- Certified Vacuum Deposition Coater

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Metalizer Operator

- Showcase your experience in various metalizing techniques and your ability to optimize processes.

- Quantify your accomplishments with specific metrics to demonstrate your impact.

- Highlight your problem-solving skills and ability to collaborate with engineers to resolve complex issues.

- Emphasize your commitment to safety and quality control in the metalizing process.

Essential Experience Highlights for a Strong Metalizer Operator Resume

- Optimized metalizing processes, reducing cycle time by 15% while maintaining product quality standards.

- Established a preventive maintenance program for metalizing equipment, resulting in a 20% reduction in downtime.

- Developed a training program for new Metalizer Operators, improving onboarding time and skill proficiency.

- Collaborated with engineers to troubleshoot complex metalization issues, ensuring timely resolution.

- Introduced automation to the metalizing process, increasing efficiency and product consistency.

- Managed and maintained metalizing equipment to ensure optimal performance and productivity.

- Inspected and tested metalized products to verify adherence to specifications and quality standards.

Frequently Asked Questions (FAQ’s) For Metalizer Operator

What are the key responsibilities of a Metalizer Operator?

The key responsibilities of a Metalizer Operator include preparing and operating metalizing equipment, monitoring and controlling process parameters, inspecting and testing metalized products, and maintaining a safe and clean work environment.

What skills are required to be a successful Metalizer Operator?

Successful Metalizer Operators possess a strong understanding of metalizing techniques, process parameters, and quality control procedures. They are also proficient in operating and maintaining metalizing equipment, and have excellent problem-solving and communication skills.

What are the career prospects for Metalizer Operators?

Metalizer Operators can advance their careers by becoming supervisors or managers, or by specializing in a particular metalizing technique or industry. They can also pursue further education to enhance their knowledge and skills.

What is the work environment of a Metalizer Operator?

Metalizer Operators typically work in manufacturing environments, operating metalizing equipment in production lines or workshops. They may be exposed to noise, fumes, and hazardous materials, and must wear appropriate protective gear.

What are the salary expectations for Metalizer Operators?

The salary expectations for Metalizer Operators vary depending on their experience, skills, and location. According to Indeed, the average salary for Metalizer Operators in the United States is around $50,000 per year.

What is the job outlook for Metalizer Operators?

The job outlook for Metalizer Operators is expected to be good in the coming years, as the demand for metalized products continues to grow in various industries.