Are you a seasoned Methods Specialist Engineer seeking a new career path? Discover our professionally built Methods Specialist Engineer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

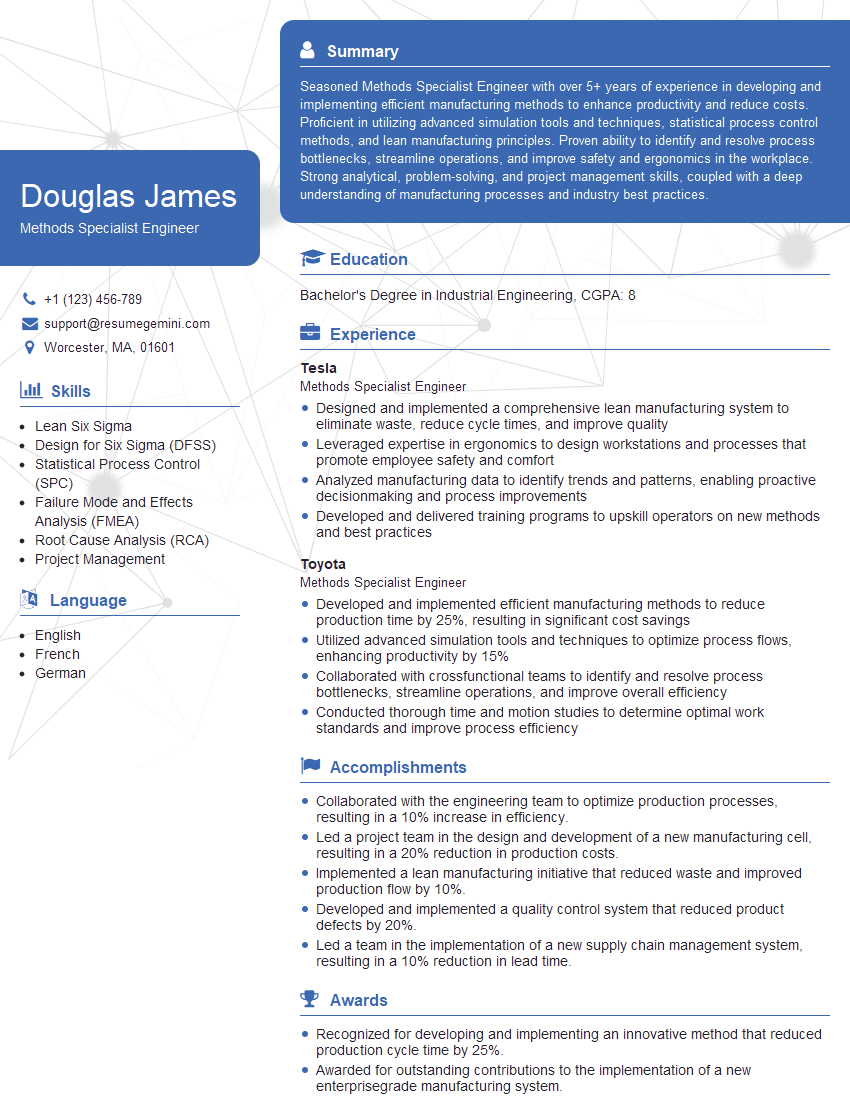

Douglas James

Methods Specialist Engineer

Summary

Seasoned Methods Specialist Engineer with over 5+ years of experience in developing and implementing efficient manufacturing methods to enhance productivity and reduce costs. Proficient in utilizing advanced simulation tools and techniques, statistical process control methods, and lean manufacturing principles. Proven ability to identify and resolve process bottlenecks, streamline operations, and improve safety and ergonomics in the workplace. Strong analytical, problem-solving, and project management skills, coupled with a deep understanding of manufacturing processes and industry best practices.

Education

Bachelor’s Degree in Industrial Engineering

January 2019

Skills

- Lean Six Sigma

- Design for Six Sigma (DFSS)

- Statistical Process Control (SPC)

- Failure Mode and Effects Analysis (FMEA)

- Root Cause Analysis (RCA)

- Project Management

Work Experience

Methods Specialist Engineer

- Designed and implemented a comprehensive lean manufacturing system to eliminate waste, reduce cycle times, and improve quality

- Leveraged expertise in ergonomics to design workstations and processes that promote employee safety and comfort

- Analyzed manufacturing data to identify trends and patterns, enabling proactive decisionmaking and process improvements

- Developed and delivered training programs to upskill operators on new methods and best practices

Methods Specialist Engineer

- Developed and implemented efficient manufacturing methods to reduce production time by 25%, resulting in significant cost savings

- Utilized advanced simulation tools and techniques to optimize process flows, enhancing productivity by 15%

- Collaborated with crossfunctional teams to identify and resolve process bottlenecks, streamline operations, and improve overall efficiency

- Conducted thorough time and motion studies to determine optimal work standards and improve process efficiency

Accomplishments

- Collaborated with the engineering team to optimize production processes, resulting in a 10% increase in efficiency.

- Led a project team in the design and development of a new manufacturing cell, resulting in a 20% reduction in production costs.

- Implemented a lean manufacturing initiative that reduced waste and improved production flow by 10%.

- Developed and implemented a quality control system that reduced product defects by 20%.

- Led a team in the implementation of a new supply chain management system, resulting in a 10% reduction in lead time.

Awards

- Recognized for developing and implementing an innovative method that reduced production cycle time by 25%.

- Awarded for outstanding contributions to the implementation of a new enterprisegrade manufacturing system.

- Received recognition for developing a novel process that improved product quality by 15%.

- Honored for exceptional contributions to the development and implementation of a new product line.

Certificates

- Certified Manufacturing Engineer (CMfgE)

- Certified Quality Engineer (CQE)

- Certified Lean Six Sigma Black Belt (CLSSBB)

- Certified Lean Six Sigma Green Belt (CLSSGB)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Methods Specialist Engineer

Highlight quantifiable achievements:

Showcase your impact on reducing production time, increasing productivity, and improving efficiency through specific metrics.Demonstrate proficiency in lean manufacturing principles:

Emphasize your experience in implementing Six Sigma, Design for Six Sigma (DFSS), and other lean methodologies.Emphasize problem-solving and analytical skills:

Showcase your ability to identify and resolve manufacturing challenges, optimize processes, and drive continuous improvement.Highlight your soft skills:

Communication, teamwork, and collaboration are essential in this role. Highlight your ability to work effectively with cross-functional teams and stakeholders.

Essential Experience Highlights for a Strong Methods Specialist Engineer Resume

- Design and implement efficient manufacturing methods to reduce production time and costs.

- Utilize advanced simulation tools and techniques to optimize process flows and enhance productivity.

- Collaborate with cross-functional teams to identify and resolve process bottlenecks, streamline operations, and improve overall efficiency.

- Conduct thorough time and motion studies to determine optimal work standards and improve process efficiency.

- Design and implement comprehensive lean manufacturing systems to eliminate waste, reduce cycle times, and improve quality.

- Leverage expertise in ergonomics to design workstations and processes that promote employee safety and comfort.

- Analyze manufacturing data to identify trends and patterns, enabling proactive decision-making and process improvements.

- Develop and deliver training programs to upskill operators on new methods and best practices.

Frequently Asked Questions (FAQ’s) For Methods Specialist Engineer

What is the primary role of a Methods Specialist Engineer?

Methods Specialist Engineers are responsible for developing and implementing efficient manufacturing methods to improve productivity, reduce costs, and enhance safety in manufacturing environments.

What are the key skills required for this role?

Core skills include proficiency in lean manufacturing principles, process optimization techniques, data analysis, project management, and strong problem-solving abilities.

What industries employ Methods Specialist Engineers?

Methods Specialist Engineers are in high demand in various industries, including automotive, aerospace, electronics, and consumer products.

What is the career path for Methods Specialist Engineers?

With experience and expertise, Methods Specialist Engineers can advance to roles such as Manufacturing Engineer, Production Manager, or Lean Six Sigma Black Belt.

How do I prepare for an interview as a Methods Specialist Engineer?

Be prepared to discuss your experience in implementing lean manufacturing practices, optimizing processes, and solving manufacturing challenges. Highlight your analytical skills, problem-solving abilities, and knowledge of industry best practices.

What are the current trends in methods engineering?

Emerging trends include the adoption of Industry 4.0 technologies, such as automation, data analytics, and artificial intelligence, to further improve manufacturing efficiency and productivity.