Are you a seasoned Methods Study Analyst seeking a new career path? Discover our professionally built Methods Study Analyst Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

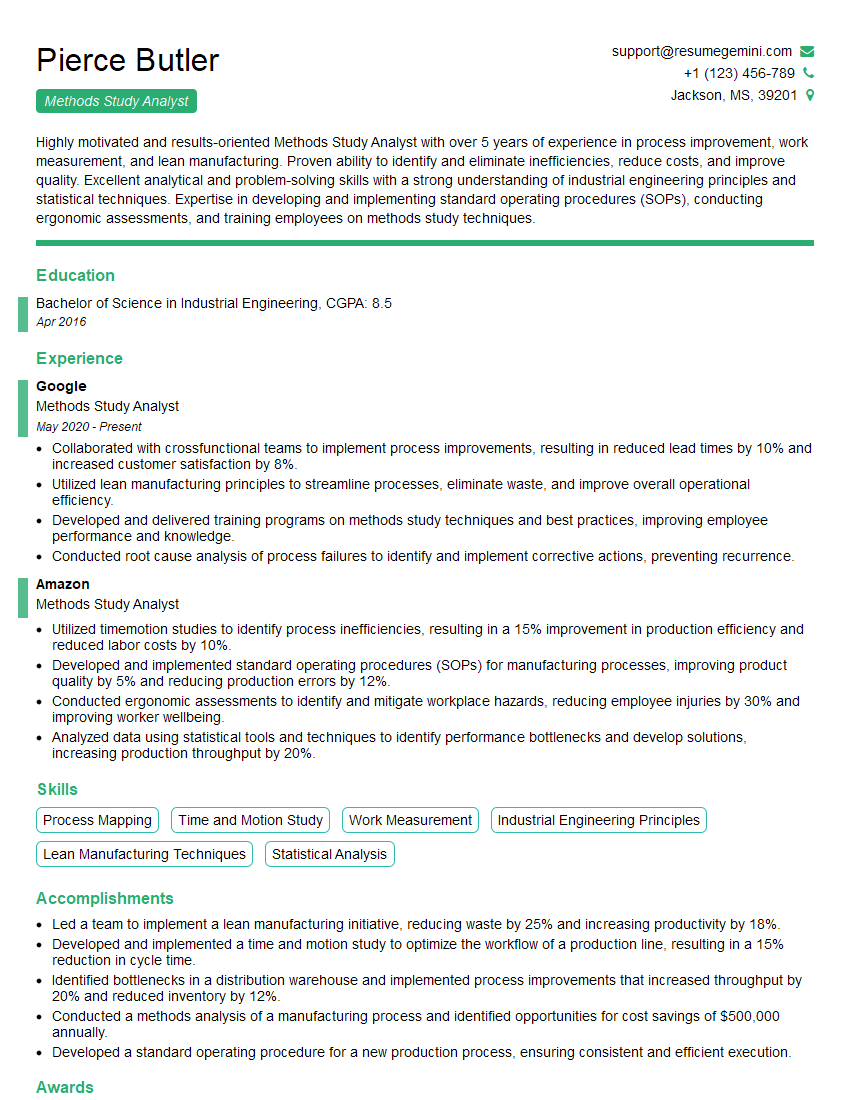

Pierce Butler

Methods Study Analyst

Summary

Highly motivated and results-oriented Methods Study Analyst with over 5 years of experience in process improvement, work measurement, and lean manufacturing. Proven ability to identify and eliminate inefficiencies, reduce costs, and improve quality. Excellent analytical and problem-solving skills with a strong understanding of industrial engineering principles and statistical techniques. Expertise in developing and implementing standard operating procedures (SOPs), conducting ergonomic assessments, and training employees on methods study techniques.

Education

Bachelor of Science in Industrial Engineering

April 2016

Skills

- Process Mapping

- Time and Motion Study

- Work Measurement

- Industrial Engineering Principles

- Lean Manufacturing Techniques

- Statistical Analysis

Work Experience

Methods Study Analyst

- Collaborated with crossfunctional teams to implement process improvements, resulting in reduced lead times by 10% and increased customer satisfaction by 8%.

- Utilized lean manufacturing principles to streamline processes, eliminate waste, and improve overall operational efficiency.

- Developed and delivered training programs on methods study techniques and best practices, improving employee performance and knowledge.

- Conducted root cause analysis of process failures to identify and implement corrective actions, preventing recurrence.

Methods Study Analyst

- Utilized timemotion studies to identify process inefficiencies, resulting in a 15% improvement in production efficiency and reduced labor costs by 10%.

- Developed and implemented standard operating procedures (SOPs) for manufacturing processes, improving product quality by 5% and reducing production errors by 12%.

- Conducted ergonomic assessments to identify and mitigate workplace hazards, reducing employee injuries by 30% and improving worker wellbeing.

- Analyzed data using statistical tools and techniques to identify performance bottlenecks and develop solutions, increasing production throughput by 20%.

Accomplishments

- Led a team to implement a lean manufacturing initiative, reducing waste by 25% and increasing productivity by 18%.

- Developed and implemented a time and motion study to optimize the workflow of a production line, resulting in a 15% reduction in cycle time.

- Identified bottlenecks in a distribution warehouse and implemented process improvements that increased throughput by 20% and reduced inventory by 12%.

- Conducted a methods analysis of a manufacturing process and identified opportunities for cost savings of $500,000 annually.

- Developed a standard operating procedure for a new production process, ensuring consistent and efficient execution.

Awards

- Recognized for exceptional contributions to improving process efficiency through innovative methods study techniques.

- Received the Analyst of the Year award for consistently exceeding performance targets in methods analysis and improvement.

- Honored with the Excellence in Methods Innovation award for developing a breakthrough approach to streamline production processes.

Certificates

- Certified Methods Study Analyst (CMSA)

- Certified Work Measurement Analyst (CWMA)

- Lean Six Sigma Black Belt

- Certified Safety Professional (CSP)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Methods Study Analyst

- Quantify your accomplishments with specific metrics to demonstrate the impact of your work.

- Highlight your expertise in specific methods study techniques, such as time and motion study, work measurement, and statistical analysis.

- Emphasize your ability to collaborate effectively with cross-functional teams and stakeholders.

- Showcase your understanding of lean manufacturing principles and your experience in implementing them to improve operational efficiency.

Essential Experience Highlights for a Strong Methods Study Analyst Resume

- Conduct time and motion studies to identify process inefficiencies and develop solutions to improve efficiency.

- Develop and implement standard operating procedures (SOPs) to ensure consistent and efficient work practices.

- Conduct ergonomic assessments to identify and mitigate workplace hazards, reducing employee injuries and improving worker wellbeing.

- Analyze data using statistical tools and techniques to identify performance bottlenecks and develop solutions to increase production throughput.

- Collaborate with cross-functional teams to implement process improvements, resulting in reduced lead times and increased customer satisfaction.

- Utilize lean manufacturing principles to streamline processes, eliminate waste, and improve overall operational efficiency.

- Develop and deliver training programs on methods study techniques and best practices to improve employee performance and knowledge.

Frequently Asked Questions (FAQ’s) For Methods Study Analyst

What is the role of a Methods Study Analyst?

A Methods Study Analyst is responsible for analyzing and improving work processes to increase efficiency, reduce costs, and improve quality. They use a variety of techniques, such as time and motion study, work measurement, and statistical analysis, to identify bottlenecks and develop solutions.

What skills are required to be a successful Methods Study Analyst?

Successful Methods Study Analysts typically have a strong understanding of industrial engineering principles, statistical techniques, and lean manufacturing practices. They also possess excellent analytical and problem-solving skills, as well as the ability to work effectively with cross-functional teams.

What are the career prospects for Methods Study Analysts?

Methods Study Analysts can advance to management positions, such as Operations Manager or Lean Manufacturing Manager. They may also specialize in a particular area, such as ergonomics or process improvement.

What is the salary range for Methods Study Analysts?

The salary range for Methods Study Analysts can vary depending on experience, location, and industry. According to Salary.com, the average salary for Methods Study Analysts in the United States is around $75,000 per year.

What is the job outlook for Methods Study Analysts?

The job outlook for Methods Study Analysts is expected to be positive over the next few years. The increasing demand for efficiency and productivity improvement is driving the demand for qualified Methods Study Analysts.

What are some tips for writing a standout Methods Study Analyst resume?

To write a standout Methods Study Analyst resume, focus on quantifying your accomplishments, highlighting your expertise in specific methods study techniques, emphasizing your ability to collaborate effectively, and showcasing your understanding of lean manufacturing principles.

What are some common interview questions for Methods Study Analyst positions?

Common interview questions for Methods Study Analyst positions include questions about your experience with specific methods study techniques, your understanding of lean manufacturing principles, and your ability to work effectively with cross-functional teams.

How can I prepare for a Methods Study Analyst interview?

To prepare for a Methods Study Analyst interview, research the company and the position, practice answering common interview questions, and prepare to discuss your experience and skills in detail.