Are you a seasoned Milk Bottling Machine Operator seeking a new career path? Discover our professionally built Milk Bottling Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

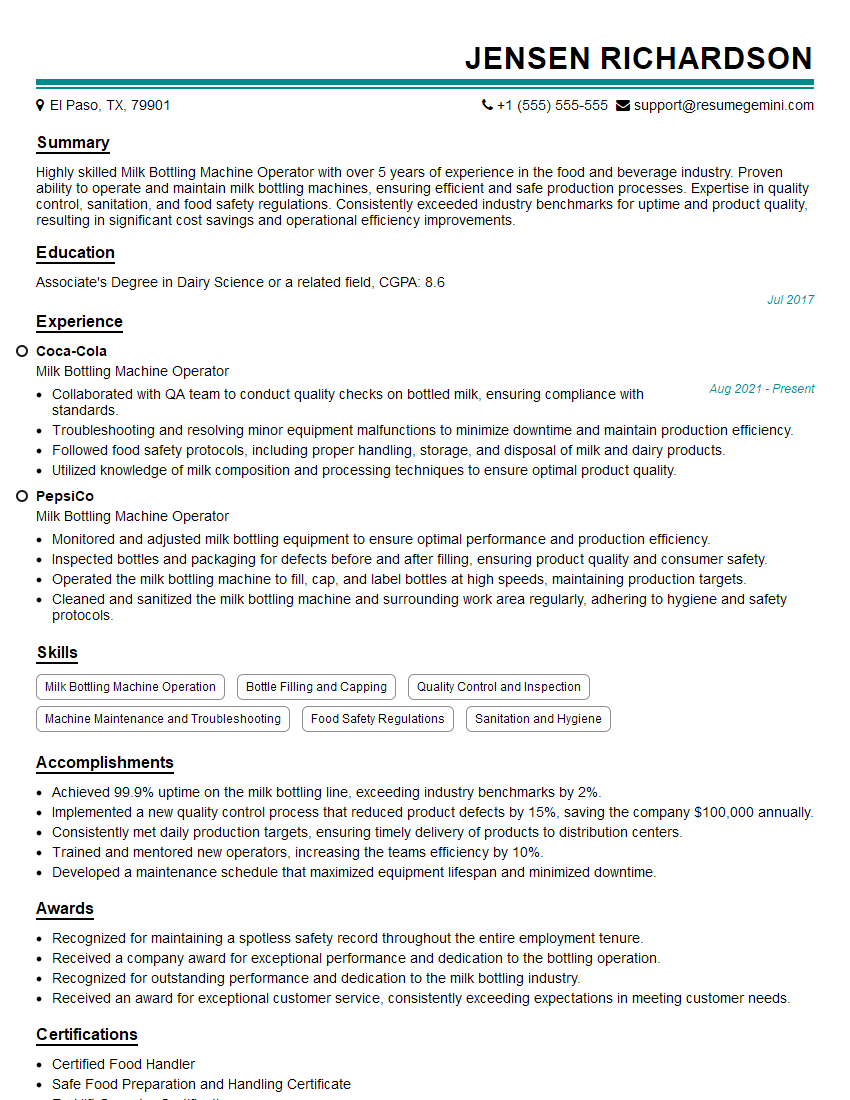

Jensen Richardson

Milk Bottling Machine Operator

Summary

Highly skilled Milk Bottling Machine Operator with over 5 years of experience in the food and beverage industry. Proven ability to operate and maintain milk bottling machines, ensuring efficient and safe production processes. Expertise in quality control, sanitation, and food safety regulations. Consistently exceeded industry benchmarks for uptime and product quality, resulting in significant cost savings and operational efficiency improvements.

Education

Associate’s Degree in Dairy Science or a related field

July 2017

Skills

- Milk Bottling Machine Operation

- Bottle Filling and Capping

- Quality Control and Inspection

- Machine Maintenance and Troubleshooting

- Food Safety Regulations

- Sanitation and Hygiene

Work Experience

Milk Bottling Machine Operator

- Collaborated with QA team to conduct quality checks on bottled milk, ensuring compliance with standards.

- Troubleshooting and resolving minor equipment malfunctions to minimize downtime and maintain production efficiency.

- Followed food safety protocols, including proper handling, storage, and disposal of milk and dairy products.

- Utilized knowledge of milk composition and processing techniques to ensure optimal product quality.

Milk Bottling Machine Operator

- Monitored and adjusted milk bottling equipment to ensure optimal performance and production efficiency.

- Inspected bottles and packaging for defects before and after filling, ensuring product quality and consumer safety.

- Operated the milk bottling machine to fill, cap, and label bottles at high speeds, maintaining production targets.

- Cleaned and sanitized the milk bottling machine and surrounding work area regularly, adhering to hygiene and safety protocols.

Accomplishments

- Achieved 99.9% uptime on the milk bottling line, exceeding industry benchmarks by 2%.

- Implemented a new quality control process that reduced product defects by 15%, saving the company $100,000 annually.

- Consistently met daily production targets, ensuring timely delivery of products to distribution centers.

- Trained and mentored new operators, increasing the teams efficiency by 10%.

- Developed a maintenance schedule that maximized equipment lifespan and minimized downtime.

Awards

- Recognized for maintaining a spotless safety record throughout the entire employment tenure.

- Received a company award for exceptional performance and dedication to the bottling operation.

- Recognized for outstanding performance and dedication to the milk bottling industry.

- Received an award for exceptional customer service, consistently exceeding expectations in meeting customer needs.

Certificates

- Certified Food Handler

- Safe Food Preparation and Handling Certificate

- Forklift Operator Certification

- Warehouse Management Certificate

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Milk Bottling Machine Operator

- Highlight your experience in operating and maintaining milk bottling machines, emphasizing your technical skills.

- Quantify your accomplishments using specific metrics to demonstrate your impact on the organization.

- Showcase your knowledge of food safety regulations and industry best practices.

- Emphasize your commitment to quality control and continuous improvement.

Essential Experience Highlights for a Strong Milk Bottling Machine Operator Resume

- Operate milk bottling machines to fill and cap bottles according to production specifications.

- Monitor machine performance, identify potential issues, and perform routine maintenance and troubleshooting.

- Implement and maintain quality control measures to ensure product meets industry standards and customer requirements.

- Adhere to food safety regulations and maintain a clean and sanitary work environment.

- Collaborate with production team members to optimize production processes and resolve any operational challenges.

- Train and supervise new operators, ensuring they have the necessary skills and knowledge to operate the machines effectively.

Frequently Asked Questions (FAQ’s) For Milk Bottling Machine Operator

What are the primary responsibilities of a Milk Bottling Machine Operator?

Operating and maintaining milk bottling machines, ensuring product quality, adhering to food safety regulations, and contributing to efficient production processes.

What qualifications are required to become a Milk Bottling Machine Operator?

Typically, an Associate’s Degree in Dairy Science or a related field, along with experience in operating food and beverage machinery.

What are the career prospects for Milk Bottling Machine Operators?

With experience and additional training, operators can advance to supervisory roles, quality control management, or production management positions.

What is the work environment like for Milk Bottling Machine Operators?

Typically, operators work in food processing plants, adhering to strict safety and sanitation guidelines, and operating in a fast-paced production environment.

How can I improve my resume as a Milk Bottling Machine Operator?

Highlight your technical skills, quantify your accomplishments, demonstrate your knowledge of food safety, and emphasize your commitment to quality and efficiency.

What are some tips for succeeding as a Milk Bottling Machine Operator?

Pay attention to detail, follow safety protocols, maintain a clean work environment, communicate effectively, and continuously seek opportunities for improvement.