Are you a seasoned Mill Turner seeking a new career path? Discover our professionally built Mill Turner Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

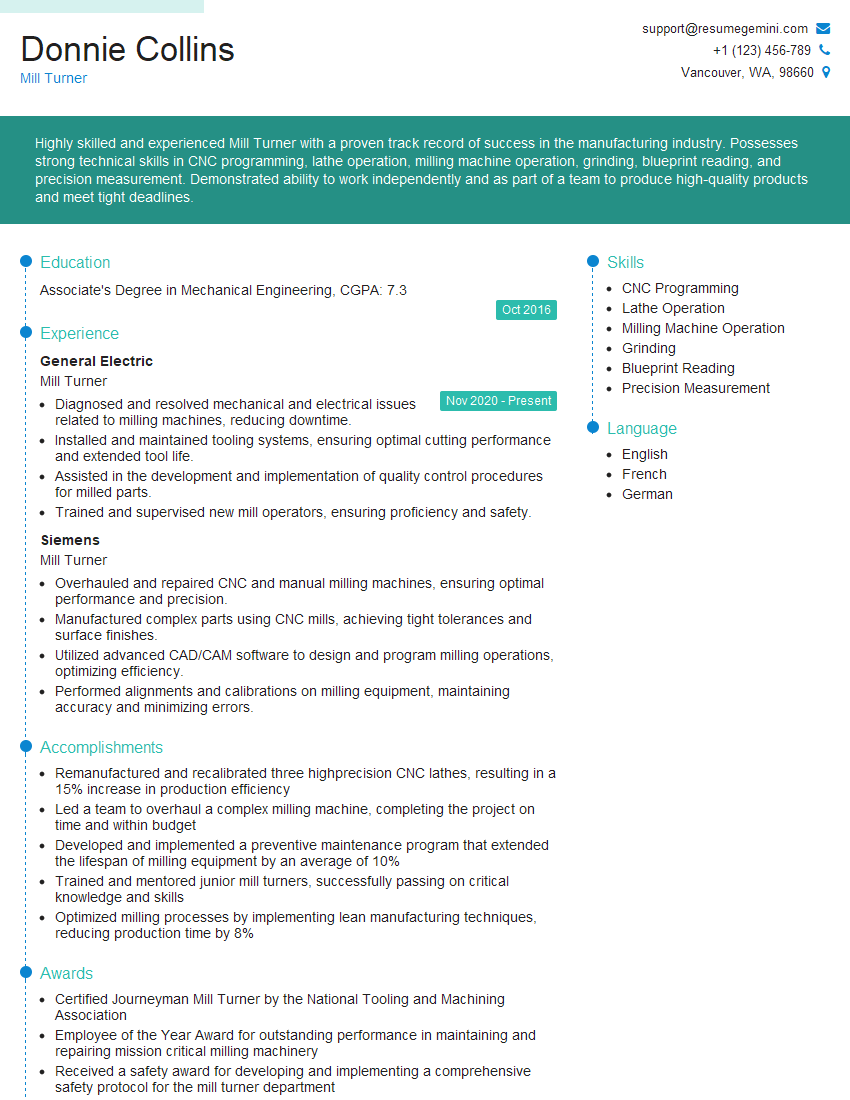

Donnie Collins

Mill Turner

Summary

Highly skilled and experienced Mill Turner with a proven track record of success in the manufacturing industry. Possesses strong technical skills in CNC programming, lathe operation, milling machine operation, grinding, blueprint reading, and precision measurement. Demonstrated ability to work independently and as part of a team to produce high-quality products and meet tight deadlines.

Education

Associate’s Degree in Mechanical Engineering

October 2016

Skills

- CNC Programming

- Lathe Operation

- Milling Machine Operation

- Grinding

- Blueprint Reading

- Precision Measurement

Work Experience

Mill Turner

- Diagnosed and resolved mechanical and electrical issues related to milling machines, reducing downtime.

- Installed and maintained tooling systems, ensuring optimal cutting performance and extended tool life.

- Assisted in the development and implementation of quality control procedures for milled parts.

- Trained and supervised new mill operators, ensuring proficiency and safety.

Mill Turner

- Overhauled and repaired CNC and manual milling machines, ensuring optimal performance and precision.

- Manufactured complex parts using CNC mills, achieving tight tolerances and surface finishes.

- Utilized advanced CAD/CAM software to design and program milling operations, optimizing efficiency.

- Performed alignments and calibrations on milling equipment, maintaining accuracy and minimizing errors.

Accomplishments

- Remanufactured and recalibrated three highprecision CNC lathes, resulting in a 15% increase in production efficiency

- Led a team to overhaul a complex milling machine, completing the project on time and within budget

- Developed and implemented a preventive maintenance program that extended the lifespan of milling equipment by an average of 10%

- Trained and mentored junior mill turners, successfully passing on critical knowledge and skills

- Optimized milling processes by implementing lean manufacturing techniques, reducing production time by 8%

Awards

- Certified Journeyman Mill Turner by the National Tooling and Machining Association

- Employee of the Year Award for outstanding performance in maintaining and repairing mission critical milling machinery

- Received a safety award for developing and implementing a comprehensive safety protocol for the mill turner department

- Excellence in Mill Turner Award for consistently demonstrating superior craftsmanship and innovation

Certificates

- Certified Millwright

- CNC Operator Certification

- Lathe Operator Certification

- Milling Machine Operator Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Mill Turner

- Highlight your experience and skills in CNC programming and operation.

- Showcase your knowledge of blueprint reading and precision measurement.

- Demonstrate your ability to work independently and as part of a team.

- Emphasize your commitment to safety and quality.

Essential Experience Highlights for a Strong Mill Turner Resume

- Set up and operate CNC machines, lathes, milling machines, and grinders to produce precision parts according to specifications.

- Interpret blueprints and drawings to determine machining requirements.

- Inspect finished parts to ensure they meet quality standards.

- Maintain and repair machinery and equipment.

- Troubleshoot and resolve production problems.

- Follow safety procedures and maintain a clean and organized work area.

Frequently Asked Questions (FAQ’s) For Mill Turner

What is the role of a Mill Turner?

A Mill Turner is responsible for operating and maintaining CNC machines, lathes, milling machines, and grinders to produce precision parts according to specifications. They interpret blueprints and drawings to determine machining requirements, inspect finished parts to ensure they meet quality standards, and maintain and repair machinery and equipment.

What skills are required to be a Mill Turner?

Mill Turners typically need an Associate’s Degree in Mechanical Engineering or a related field, along with experience in CNC programming and operation, blueprint reading, precision measurement, and machine maintenance.

What is the work environment of a Mill Turner?

Mill Turners typically work in manufacturing facilities, operating machinery in a fast-paced and often noisy environment.

What is the salary range for a Mill Turner?

The salary range for a Mill Turner can vary depending on experience, location, and employer. According to the U.S. Bureau of Labor Statistics, the median annual salary for Mill Turners is around $45,000.

What are the career prospects for a Mill Turner?

Mill Turners can advance to positions such as CNC programmer, machinist, or supervisor. With additional education and experience, they may also move into management or engineering roles.