Are you a seasoned Miller Apprentice seeking a new career path? Discover our professionally built Miller Apprentice Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

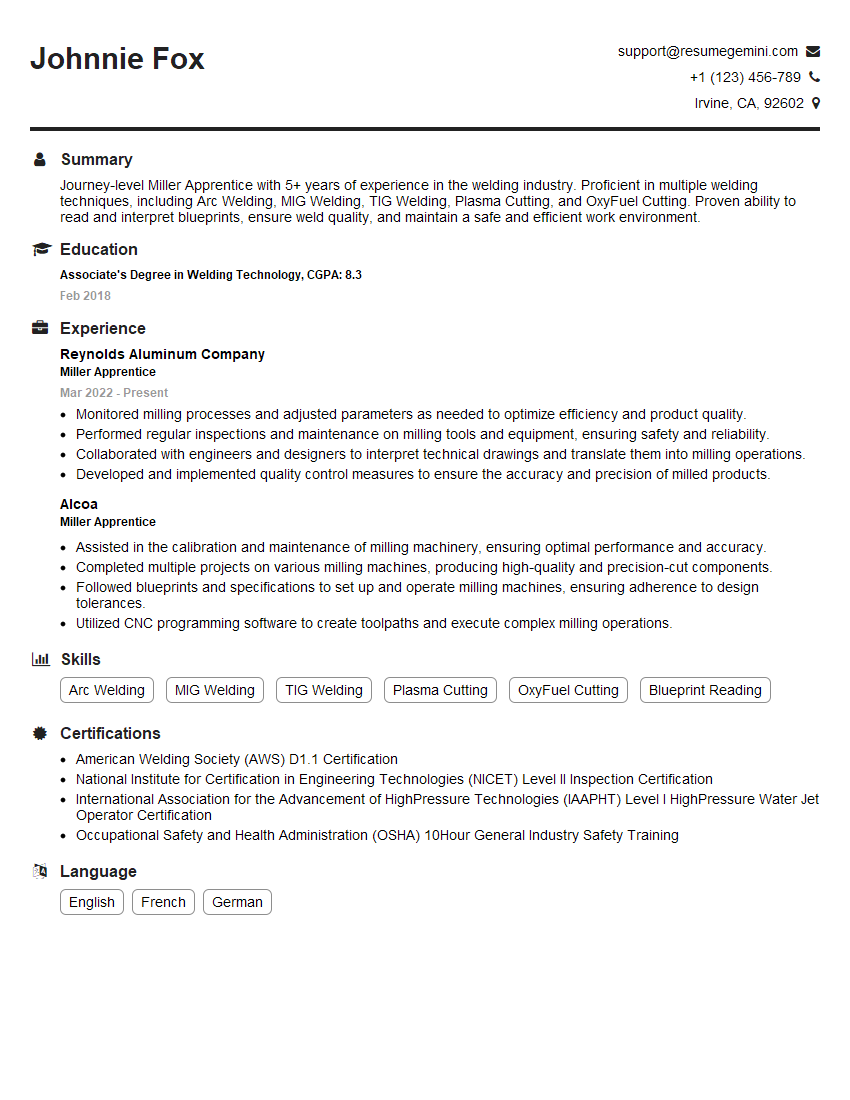

Johnnie Fox

Miller Apprentice

Summary

Journey-level Miller Apprentice with 5+ years of experience in the welding industry. Proficient in multiple welding techniques, including Arc Welding, MIG Welding, TIG Welding, Plasma Cutting, and OxyFuel Cutting. Proven ability to read and interpret blueprints, ensure weld quality, and maintain a safe and efficient work environment.

Education

Associate’s Degree in Welding Technology

February 2018

Skills

- Arc Welding

- MIG Welding

- TIG Welding

- Plasma Cutting

- OxyFuel Cutting

- Blueprint Reading

Work Experience

Miller Apprentice

- Monitored milling processes and adjusted parameters as needed to optimize efficiency and product quality.

- Performed regular inspections and maintenance on milling tools and equipment, ensuring safety and reliability.

- Collaborated with engineers and designers to interpret technical drawings and translate them into milling operations.

- Developed and implemented quality control measures to ensure the accuracy and precision of milled products.

Miller Apprentice

- Assisted in the calibration and maintenance of milling machinery, ensuring optimal performance and accuracy.

- Completed multiple projects on various milling machines, producing high-quality and precision-cut components.

- Followed blueprints and specifications to set up and operate milling machines, ensuring adherence to design tolerances.

- Utilized CNC programming software to create toolpaths and execute complex milling operations.

Certificates

- American Welding Society (AWS) D1.1 Certification

- National Institute for Certification in Engineering Technologies (NICET) Level II Inspection Certification

- International Association for the Advancement of HighPressure Technologies (IAAPHT) Level I HighPressure Water Jet Operator Certification

- Occupational Safety and Health Administration (OSHA) 10Hour General Industry Safety Training

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Miller Apprentice

- Highlight your experience and skills in Miller welding machines specifically.

- Quantify your accomplishments whenever possible, using specific numbers and metrics.

- Include keywords from the job description in your resume to improve its visibility to potential employers.

- Proofread your resume carefully for any errors in grammar, spelling, or punctuation.

- Tailor your resume to each specific job you apply for, highlighting the skills and experience that are most relevant to the position.

Essential Experience Highlights for a Strong Miller Apprentice Resume

- Operate and maintain welding equipment, including Miller welding machines.

- Interpret blueprints and welding specifications to determine appropriate welding procedures.

- Prepare welding surfaces, including cleaning, grinding, and fitting metal parts.

- Perform various welding techniques, such as Arc Welding, MIG Welding, TIG Welding, Plasma Cutting, and OxyFuel Cutting.

- Inspect welds to ensure quality and adherence to specifications.

- Maintain a clean and organized work area, ensuring safety and efficiency.

- Collaborate with other tradesmen and engineers to complete welding projects on time and within budget.

Frequently Asked Questions (FAQ’s) For Miller Apprentice

What is a Miller Apprentice?

A Miller Apprentice is a skilled welder who has received specialized training on Miller welding equipment. They are typically employed by companies that use Miller welding machines in their manufacturing processes.

What are the benefits of becoming a Miller Apprentice?

Miller Apprentices can benefit from increased job opportunities, higher earning potential, and the opportunity to work with the latest welding technology.

What are the requirements to become a Miller Apprentice?

To become a Miller Apprentice, you typically need to have a high school diploma or equivalent, as well as some experience in welding. You will also need to complete a Miller apprenticeship program, which can take several years to complete.

What are the career prospects for Miller Apprentices?

Miller Apprentices can go on to have successful careers in the welding industry. They can work in a variety of settings, including manufacturing, construction, and shipbuilding.

How can I find a Miller apprenticeship program?

You can find Miller apprenticeship programs by contacting your local Miller distributor or by searching online.

What is the average salary for a Miller Apprentice?

The average salary for a Miller Apprentice can vary depending on experience, location, and industry. However, according to the U.S. Bureau of Labor Statistics, the median annual salary for welders, cutters, solderers, and brazers was $47,080 in May 2021.