Are you a seasoned Millwright Apprentice seeking a new career path? Discover our professionally built Millwright Apprentice Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

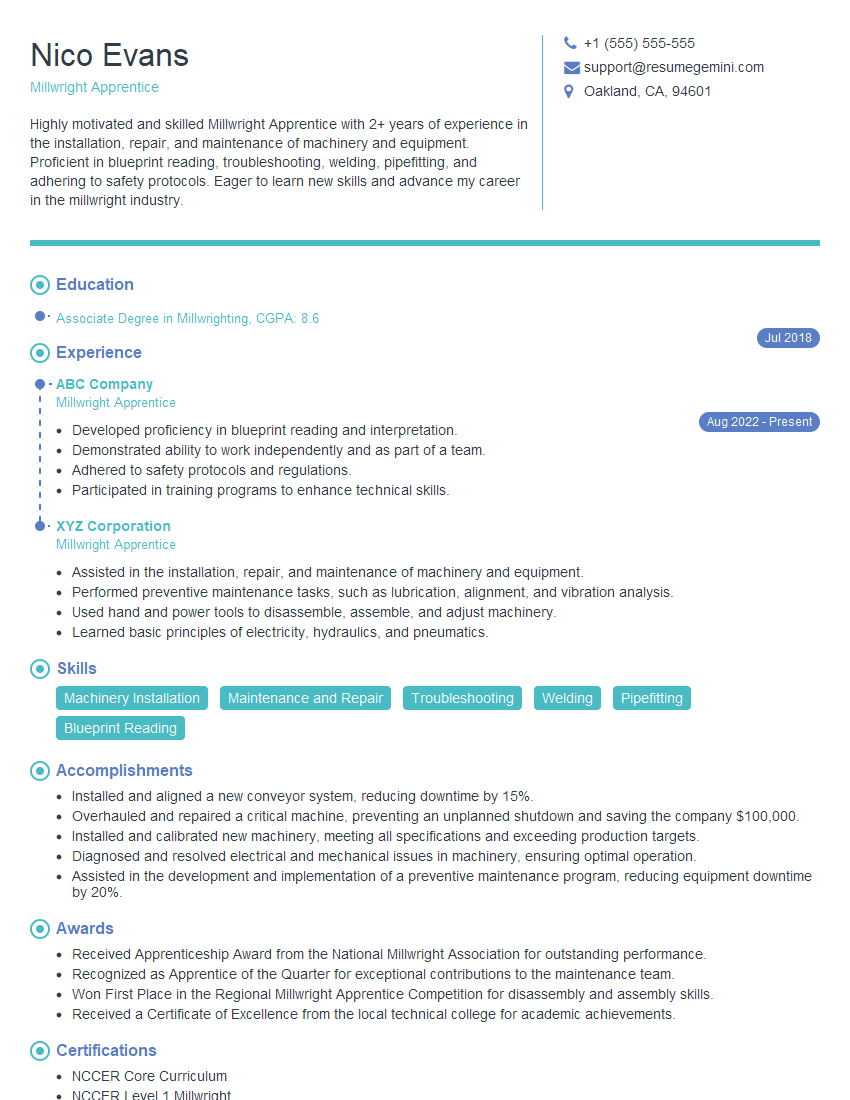

Nico Evans

Millwright Apprentice

Summary

Highly motivated and skilled Millwright Apprentice with 2+ years of experience in the installation, repair, and maintenance of machinery and equipment. Proficient in blueprint reading, troubleshooting, welding, pipefitting, and adhering to safety protocols. Eager to learn new skills and advance my career in the millwright industry.

Education

Associate Degree in Millwrighting

July 2018

Skills

- Machinery Installation

- Maintenance and Repair

- Troubleshooting

- Welding

- Pipefitting

- Blueprint Reading

Work Experience

Millwright Apprentice

- Developed proficiency in blueprint reading and interpretation.

- Demonstrated ability to work independently and as part of a team.

- Adhered to safety protocols and regulations.

- Participated in training programs to enhance technical skills.

Millwright Apprentice

- Assisted in the installation, repair, and maintenance of machinery and equipment.

- Performed preventive maintenance tasks, such as lubrication, alignment, and vibration analysis.

- Used hand and power tools to disassemble, assemble, and adjust machinery.

- Learned basic principles of electricity, hydraulics, and pneumatics.

Accomplishments

- Installed and aligned a new conveyor system, reducing downtime by 15%.

- Overhauled and repaired a critical machine, preventing an unplanned shutdown and saving the company $100,000.

- Installed and calibrated new machinery, meeting all specifications and exceeding production targets.

- Diagnosed and resolved electrical and mechanical issues in machinery, ensuring optimal operation.

- Assisted in the development and implementation of a preventive maintenance program, reducing equipment downtime by 20%.

Awards

- Received Apprenticeship Award from the National Millwright Association for outstanding performance.

- Recognized as Apprentice of the Quarter for exceptional contributions to the maintenance team.

- Won First Place in the Regional Millwright Apprentice Competition for disassembly and assembly skills.

- Received a Certificate of Excellence from the local technical college for academic achievements.

Certificates

- NCCER Core Curriculum

- NCCER Level 1 Millwright

- ANSI/ASME B56.7 Rigging and Lifting

- OSHA 10-Hour General Industry Safety

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Millwright Apprentice

- Highlight your technical skills and experience in your resume

- Showcase your ability to work independently and as part of a team

- Emphasize your commitment to safety and adherence to protocols

- Tailor your resume to each job you apply for, highlighting the skills and experience most relevant to the position

Essential Experience Highlights for a Strong Millwright Apprentice Resume

- Assisted in the installation, repair, and maintenance of machinery and equipment

- Performed preventive maintenance tasks, such as lubrication, alignment, and vibration analysis

- Used hand and power tools to disassemble, assemble, and adjust machinery

- Learned basic principles of electricity, hydraulics, and pneumatics

- Developed proficiency in blueprint reading and interpretation

- Demonstrated ability to work independently and as part of a team

- Adhered to safety protocols and regulations

- Participated in training programs to enhance technical skills

Frequently Asked Questions (FAQ’s) For Millwright Apprentice

What is a Millwright Apprentice?

A Millwright Apprentice is an individual who is training to become a Millwright, a skilled tradesperson who installs, repairs, and maintains machinery and equipment in industrial settings

What are the qualifications to become a Millwright Apprentice?

Typically, a high school diploma or equivalent is required, along with basic mechanical aptitude and physical fitness. Some employers may also require a formal apprenticeship program or coursework in millwrighting

What are the job duties of a Millwright Apprentice?

Millwright Apprentices assist experienced Millwrights with a variety of tasks, including installing, repairing, and maintaining machinery and equipment, performing preventive maintenance, troubleshooting, and adhering to safety protocols

What are the career prospects for Millwright Apprentices?

Millwright Apprentices can advance to become Millwrights, who are in high demand in various industries, including manufacturing, construction, and mining. With experience and additional training, Millwrights can also move into supervisory or management roles

What are the salary expectations for Millwright Apprentices?

Millwright Apprentices typically earn an hourly wage that increases as they gain experience and skills. According to the U.S. Bureau of Labor Statistics, the median annual salary for Millwrights in May 2022 was $59,850

What are the working conditions for Millwright Apprentices?

Millwright Apprentices typically work in industrial settings, where they may be exposed to noise, dust, and hazardous materials. They may also work in various weather conditions and may be required to work overtime or on weekends

What are the safety precautions that Millwright Apprentices should take?

Millwright Apprentices should always wear appropriate safety gear, including hard hats, safety glasses, and gloves. They should also be aware of their surroundings and potential hazards, and follow all safety protocols and procedures