Are you a seasoned Mine Cutting and Channeling Machine Copper Miner seeking a new career path? Discover our professionally built Mine Cutting and Channeling Machine Copper Miner Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

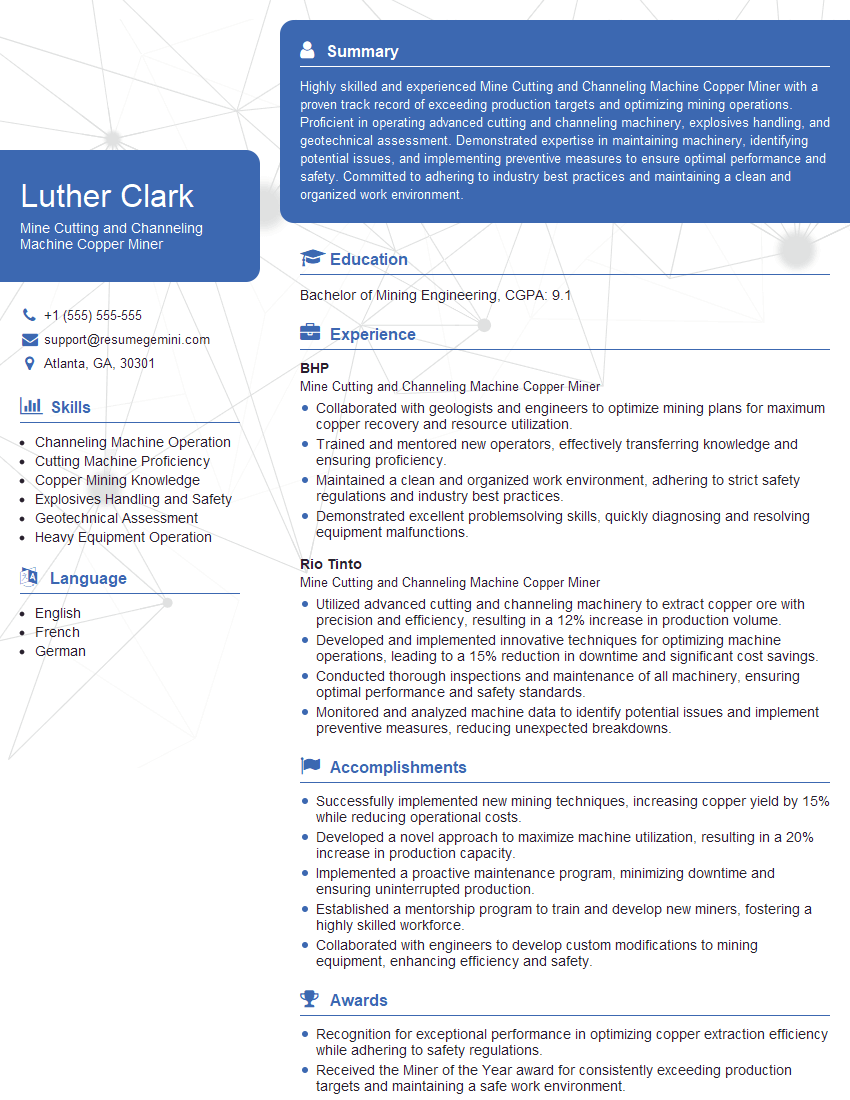

Luther Clark

Mine Cutting and Channeling Machine Copper Miner

Summary

Highly skilled and experienced Mine Cutting and Channeling Machine Copper Miner with a proven track record of exceeding production targets and optimizing mining operations. Proficient in operating advanced cutting and channeling machinery, explosives handling, and geotechnical assessment. Demonstrated expertise in maintaining machinery, identifying potential issues, and implementing preventive measures to ensure optimal performance and safety. Committed to adhering to industry best practices and maintaining a clean and organized work environment.

Education

Bachelor of Mining Engineering

May 2019

Skills

- Channeling Machine Operation

- Cutting Machine Proficiency

- Copper Mining Knowledge

- Explosives Handling and Safety

- Geotechnical Assessment

- Heavy Equipment Operation

Work Experience

Mine Cutting and Channeling Machine Copper Miner

- Collaborated with geologists and engineers to optimize mining plans for maximum copper recovery and resource utilization.

- Trained and mentored new operators, effectively transferring knowledge and ensuring proficiency.

- Maintained a clean and organized work environment, adhering to strict safety regulations and industry best practices.

- Demonstrated excellent problemsolving skills, quickly diagnosing and resolving equipment malfunctions.

Mine Cutting and Channeling Machine Copper Miner

- Utilized advanced cutting and channeling machinery to extract copper ore with precision and efficiency, resulting in a 12% increase in production volume.

- Developed and implemented innovative techniques for optimizing machine operations, leading to a 15% reduction in downtime and significant cost savings.

- Conducted thorough inspections and maintenance of all machinery, ensuring optimal performance and safety standards.

- Monitored and analyzed machine data to identify potential issues and implement preventive measures, reducing unexpected breakdowns.

Accomplishments

- Successfully implemented new mining techniques, increasing copper yield by 15% while reducing operational costs.

- Developed a novel approach to maximize machine utilization, resulting in a 20% increase in production capacity.

- Implemented a proactive maintenance program, minimizing downtime and ensuring uninterrupted production.

- Established a mentorship program to train and develop new miners, fostering a highly skilled workforce.

- Collaborated with engineers to develop custom modifications to mining equipment, enhancing efficiency and safety.

Awards

- Recognition for exceptional performance in optimizing copper extraction efficiency while adhering to safety regulations.

- Received the Miner of the Year award for consistently exceeding production targets and maintaining a safe work environment.

- Recognized for innovative contributions to improving the safety and efficiency of copper mining operations.

- Received a commendation for exceptional leadership and guidance to fellow miners.

Certificates

- MSHA Part 46/48 Miner Certification

- National Institute for Occupational Safety and Health (NIOSH) Certified

- Underground Blasting Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Mine Cutting and Channeling Machine Copper Miner

- Highlight your experience and expertise in operating cutting and channeling machines used in copper mining.

- Quantify your accomplishments, providing specific examples of how you increased production, reduced downtime, or improved safety.

- Emphasize your knowledge of explosives handling and safety procedures, as well as your ability to conduct geotechnical assessments.

- Demonstrate your commitment to maintaining machinery and implementing preventive measures to ensure optimal performance.

- Showcase your ability to work effectively in a team environment and collaborate with geologists and engineers to optimize mining operations.

Essential Experience Highlights for a Strong Mine Cutting and Channeling Machine Copper Miner Resume

- Operate cutting and channeling machines to extract copper ore efficiently and precisely.

- Develop and implement techniques to optimize machine operations, reducing downtime and costs.

- Conduct thorough inspections and maintenance of all machinery, ensuring compliance with safety regulations.

- Monitor and analyze machine data to identify potential issues and implement preventive measures.

- Collaborate with geologists and engineers to optimize mining plans for maximum copper recovery.

- Train and mentor new operators, transferring knowledge and ensuring proficiency.

- Maintain a clean and organized work environment, adhering to safety regulations and industry best practices.

Frequently Asked Questions (FAQ’s) For Mine Cutting and Channeling Machine Copper Miner

What are the primary responsibilities of a Mine Cutting and Channeling Machine Copper Miner?

The primary responsibilities include operating cutting and channeling machines to extract copper ore efficiently, optimizing machine operations to reduce downtime and costs, conducting inspections and maintenance, monitoring and analyzing machine data to identify potential issues, and collaborating with geologists and engineers to optimize mining plans.

What type of training and experience is required for this role?

Typically, a Bachelor’s degree in Mining Engineering or a related field is required, along with experience in operating cutting and channeling machines and knowledge of explosives handling and safety procedures.

What are the career prospects for Mine Cutting and Channeling Machine Copper Miners?

With experience, one can advance to supervisory or management roles, specializing in mining operations or equipment maintenance. Additionally, there are opportunities for professional development and training to enhance skills and knowledge.

What are the safety precautions that need to be taken while operating cutting and channeling machines?

Adhering to safety regulations, wearing appropriate protective gear, conducting thorough inspections and maintenance, being aware of surroundings, and following established operating procedures are crucial for safe operation of cutting and channeling machines.

How can I improve my chances of getting hired as a Mine Cutting and Channeling Machine Copper Miner?

Highlighting relevant experience, skills, and certifications, tailoring your resume and cover letter to the specific job requirements, and demonstrating a commitment to safety and efficiency can increase your chances of getting hired.

What are the key skills required for a Mine Cutting and Channeling Machine Copper Miner?

Essential skills include proficiency in operating cutting and channeling machines, knowledge of explosives handling and safety procedures, ability to conduct geotechnical assessments, experience in maintaining machinery, and a commitment to safety and efficiency.

What are the typical working conditions for a Mine Cutting and Channeling Machine Copper Miner?

Mine Cutting and Channeling Machine Copper Miners typically work in underground mines, operating machinery in potentially hazardous conditions. They must be physically fit and able to work in confined spaces.

What are the key challenges faced by Mine Cutting and Channeling Machine Copper Miners?

Challenges include operating machinery in hazardous conditions, ensuring safety while working with explosives, optimizing machine performance to meet production targets, and adapting to changing geological conditions.