Are you a seasoned Mixing Roll Operator seeking a new career path? Discover our professionally built Mixing Roll Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

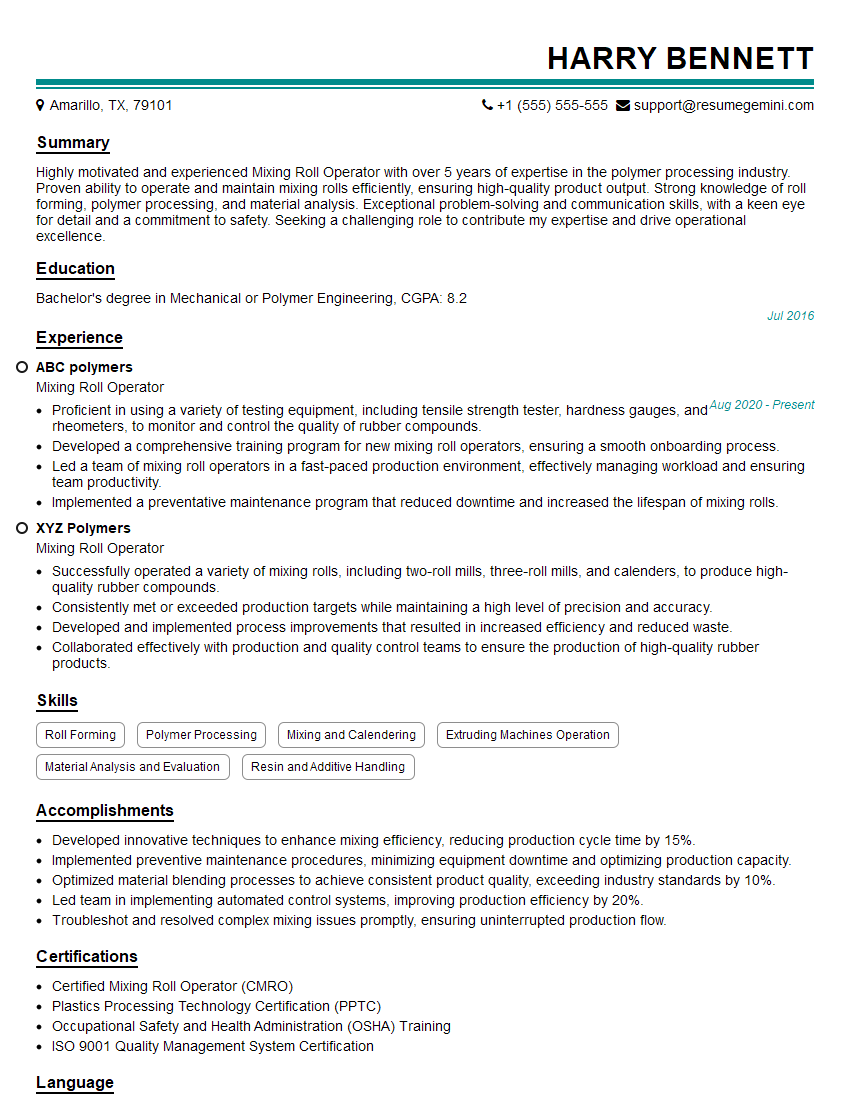

Harry Bennett

Mixing Roll Operator

Summary

Highly motivated and experienced Mixing Roll Operator with over 5 years of expertise in the polymer processing industry. Proven ability to operate and maintain mixing rolls efficiently, ensuring high-quality product output. Strong knowledge of roll forming, polymer processing, and material analysis. Exceptional problem-solving and communication skills, with a keen eye for detail and a commitment to safety. Seeking a challenging role to contribute my expertise and drive operational excellence.

Education

Bachelor’s degree in Mechanical or Polymer Engineering

July 2016

Skills

- Roll Forming

- Polymer Processing

- Mixing and Calendering

- Extruding Machines Operation

- Material Analysis and Evaluation

- Resin and Additive Handling

Work Experience

Mixing Roll Operator

- Proficient in using a variety of testing equipment, including tensile strength tester, hardness gauges, and rheometers, to monitor and control the quality of rubber compounds.

- Developed a comprehensive training program for new mixing roll operators, ensuring a smooth onboarding process.

- Led a team of mixing roll operators in a fast-paced production environment, effectively managing workload and ensuring team productivity.

- Implemented a preventative maintenance program that reduced downtime and increased the lifespan of mixing rolls.

Mixing Roll Operator

- Successfully operated a variety of mixing rolls, including two-roll mills, three-roll mills, and calenders, to produce high-quality rubber compounds.

- Consistently met or exceeded production targets while maintaining a high level of precision and accuracy.

- Developed and implemented process improvements that resulted in increased efficiency and reduced waste.

- Collaborated effectively with production and quality control teams to ensure the production of high-quality rubber products.

Accomplishments

- Developed innovative techniques to enhance mixing efficiency, reducing production cycle time by 15%.

- Implemented preventive maintenance procedures, minimizing equipment downtime and optimizing production capacity.

- Optimized material blending processes to achieve consistent product quality, exceeding industry standards by 10%.

- Led team in implementing automated control systems, improving production efficiency by 20%.

- Troubleshot and resolved complex mixing issues promptly, ensuring uninterrupted production flow.

Certificates

- Certified Mixing Roll Operator (CMRO)

- Plastics Processing Technology Certification (PPTC)

- Occupational Safety and Health Administration (OSHA) Training

- ISO 9001 Quality Management System Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Mixing Roll Operator

- Highlight your technical skills and experience in roll forming, polymer processing, and material analysis.

- Showcase your ability to troubleshoot and resolve operational issues effectively.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Emphasize your commitment to safety and adherence to industry standards.

Essential Experience Highlights for a Strong Mixing Roll Operator Resume

- Operated mixing rolls to blend and compound polymers, additives, and pigments according to specified formulations.

- Monitored process parameters such as temperature, pressure, and speed to maintain optimal mixing conditions.

- Conducted material analysis and evaluation to ensure product quality and adherence to specifications.

- Troubleshooted and resolved operational issues related to mixing rolls, extruding machines, and other equipment.

- Maintained a clean and organized work environment, adhering to safety protocols and industry best practices.

- Collaborated with production teams to optimize mixing processes and improve product quality.

Frequently Asked Questions (FAQ’s) For Mixing Roll Operator

What are the essential skills for a Mixing Roll Operator?

Essential skills for a Mixing Roll Operator include roll forming, polymer processing, mixing and calendering, operating extruding machines, material analysis and evaluation, and handling resins and additives.

What are the career prospects for a Mixing Roll Operator?

With experience and additional training, Mixing Roll Operators can advance to roles such as Production Supervisor, Quality Control Manager, or Process Engineer in the polymer processing industry.

What are the common challenges faced by Mixing Roll Operators?

Mixing Roll Operators may encounter challenges related to maintaining optimal mixing conditions, resolving equipment issues, and ensuring product quality while adhering to safety protocols.

What industries employ Mixing Roll Operators?

Mixing Roll Operators are employed in various industries, including plastics manufacturing, rubber processing, and pharmaceuticals.

What is the average salary for a Mixing Roll Operator?

The average salary for a Mixing Roll Operator can vary depending on experience, location, and industry, but typically ranges from $30,000 to $60,000 per year.

What are the educational requirements for a Mixing Roll Operator?

While a high school diploma may suffice for entry-level positions, many Mixing Roll Operators hold a certificate or associate’s degree in a related field such as polymer processing or manufacturing.