Are you a seasoned Mixing Tank Operator seeking a new career path? Discover our professionally built Mixing Tank Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

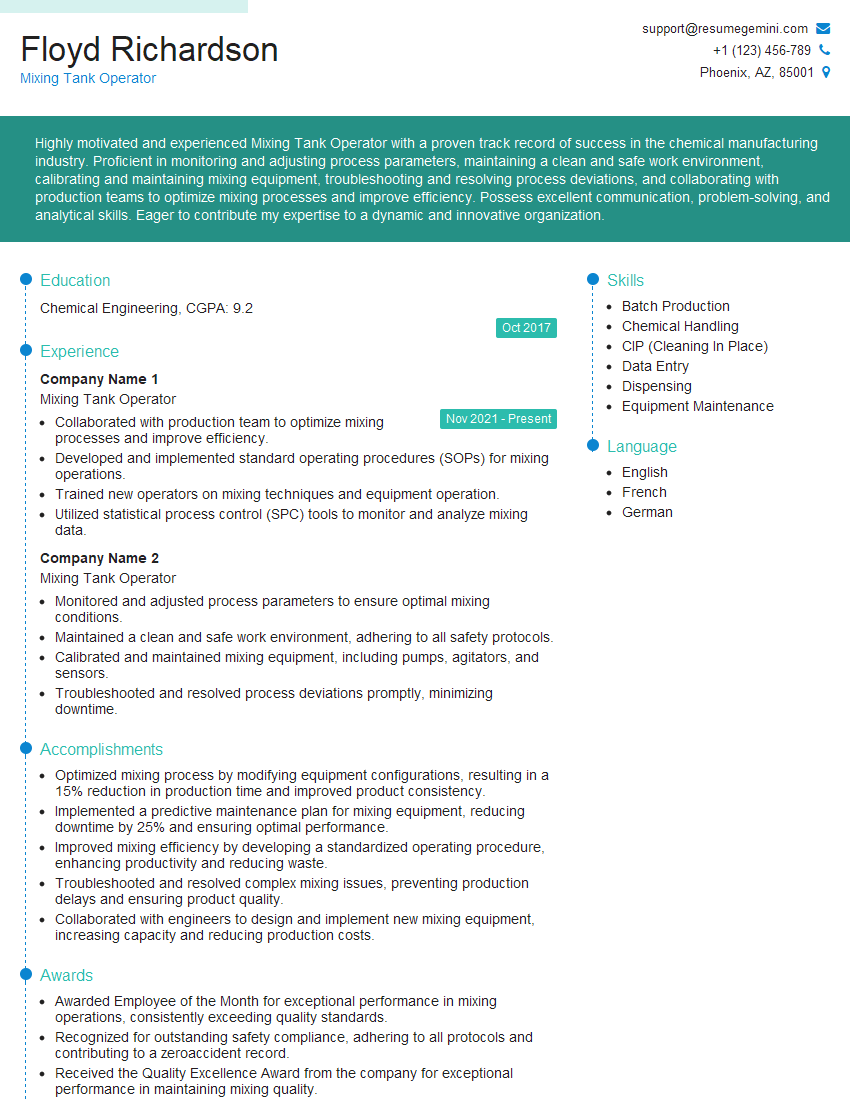

Floyd Richardson

Mixing Tank Operator

Summary

Highly motivated and experienced Mixing Tank Operator with a proven track record of success in the chemical manufacturing industry. Proficient in monitoring and adjusting process parameters, maintaining a clean and safe work environment, calibrating and maintaining mixing equipment, troubleshooting and resolving process deviations, and collaborating with production teams to optimize mixing processes and improve efficiency. Possess excellent communication, problem-solving, and analytical skills. Eager to contribute my expertise to a dynamic and innovative organization.

Education

Chemical Engineering

October 2017

Skills

- Batch Production

- Chemical Handling

- CIP (Cleaning In Place)

- Data Entry

- Dispensing

- Equipment Maintenance

Work Experience

Mixing Tank Operator

- Collaborated with production team to optimize mixing processes and improve efficiency.

- Developed and implemented standard operating procedures (SOPs) for mixing operations.

- Trained new operators on mixing techniques and equipment operation.

- Utilized statistical process control (SPC) tools to monitor and analyze mixing data.

Mixing Tank Operator

- Monitored and adjusted process parameters to ensure optimal mixing conditions.

- Maintained a clean and safe work environment, adhering to all safety protocols.

- Calibrated and maintained mixing equipment, including pumps, agitators, and sensors.

- Troubleshooted and resolved process deviations promptly, minimizing downtime.

Accomplishments

- Optimized mixing process by modifying equipment configurations, resulting in a 15% reduction in production time and improved product consistency.

- Implemented a predictive maintenance plan for mixing equipment, reducing downtime by 25% and ensuring optimal performance.

- Improved mixing efficiency by developing a standardized operating procedure, enhancing productivity and reducing waste.

- Troubleshooted and resolved complex mixing issues, preventing production delays and ensuring product quality.

- Collaborated with engineers to design and implement new mixing equipment, increasing capacity and reducing production costs.

Awards

- Awarded Employee of the Month for exceptional performance in mixing operations, consistently exceeding quality standards.

- Recognized for outstanding safety compliance, adhering to all protocols and contributing to a zeroaccident record.

- Received the Quality Excellence Award from the company for exceptional performance in maintaining mixing quality.

- Honored with the Safety Champion Award for promoting a strong safety culture and preventing workplace incidents.

Certificates

- OSHA 30-Hour Hazmat Certification

- EPA 608 Refrigerant Certification

- ISO 9001:2015 Lead Auditor Certification

- ASME BPE Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Mixing Tank Operator

- Highlight your specific skills and experience that are relevant to the job requirements.

- Quantify your accomplishments with specific metrics and data whenever possible.

- Proofread your resume carefully for any errors in grammar or spelling.

- Tailor your resume to each job you apply for, emphasizing the skills and experience that are most relevant to the position.

- Consider including a cover letter that highlights your interest in the position and how your skills can benefit the organization.

Essential Experience Highlights for a Strong Mixing Tank Operator Resume

- Monitored and adjusted process parameters, such as temperature, pH, and flow rate, to ensure optimal mixing conditions.

- Maintained a clean and safe work environment by adhering to all safety protocols, including proper handling and storage of chemicals.

- Calibrated and maintained mixing equipment, including pumps, agitators, and sensors, to ensure accurate and reliable operation.

- Troubleshooted and resolved process deviations promptly, minimizing downtime and ensuring adherence to production schedules.

- Collaborated with production teams to optimize mixing processes and improve efficiency, resulting in increased productivity and cost savings.

- Developed and implemented standard operating procedures (SOPs) for mixing operations to ensure consistent and efficient practices.

- Trained new operators on mixing techniques and equipment operation, fostering a knowledgeable and skilled workforce.

Frequently Asked Questions (FAQ’s) For Mixing Tank Operator

What are the primary responsibilities of a Mixing Tank Operator?

Mixing Tank Operators are responsible for monitoring and adjusting process parameters, maintaining a safe work environment, calibrating and maintaining equipment, troubleshooting and resolving process deviations, and collaborating with production teams to optimize processes.

What qualifications are typically required to become a Mixing Tank Operator?

Typically, Mixing Tank Operators have a high school diploma or equivalent and may have completed additional training or coursework in chemical engineering or a related field.

What are the key skills that employers look for in Mixing Tank Operators?

Mixing Tank Operators should possess strong communication, problem-solving, and analytical skills, as well as a thorough understanding of chemical handling and safety protocols.

What are the typical working conditions for Mixing Tank Operators?

Mixing Tank Operators typically work indoors in chemical manufacturing facilities, and may be exposed to hazardous chemicals and machinery.

What are the expected career prospects for Mixing Tank Operators?

Mixing Tank Operators with experience and additional training may advance to supervisory or management positions within the chemical manufacturing industry.

What is the average salary for Mixing Tank Operators?

The average annual salary for Mixing Tank Operators varies depending on experience, location, and industry, but typically ranges between $30,000 and $50,000.

What is the job outlook for Mixing Tank Operators?

The job outlook for Mixing Tank Operators is expected to be favorable in the coming years due to the growing demand for chemical products and the need for skilled workers to operate and maintain mixing equipment.