Are you a seasoned Molasses and Caramel Operator seeking a new career path? Discover our professionally built Molasses and Caramel Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

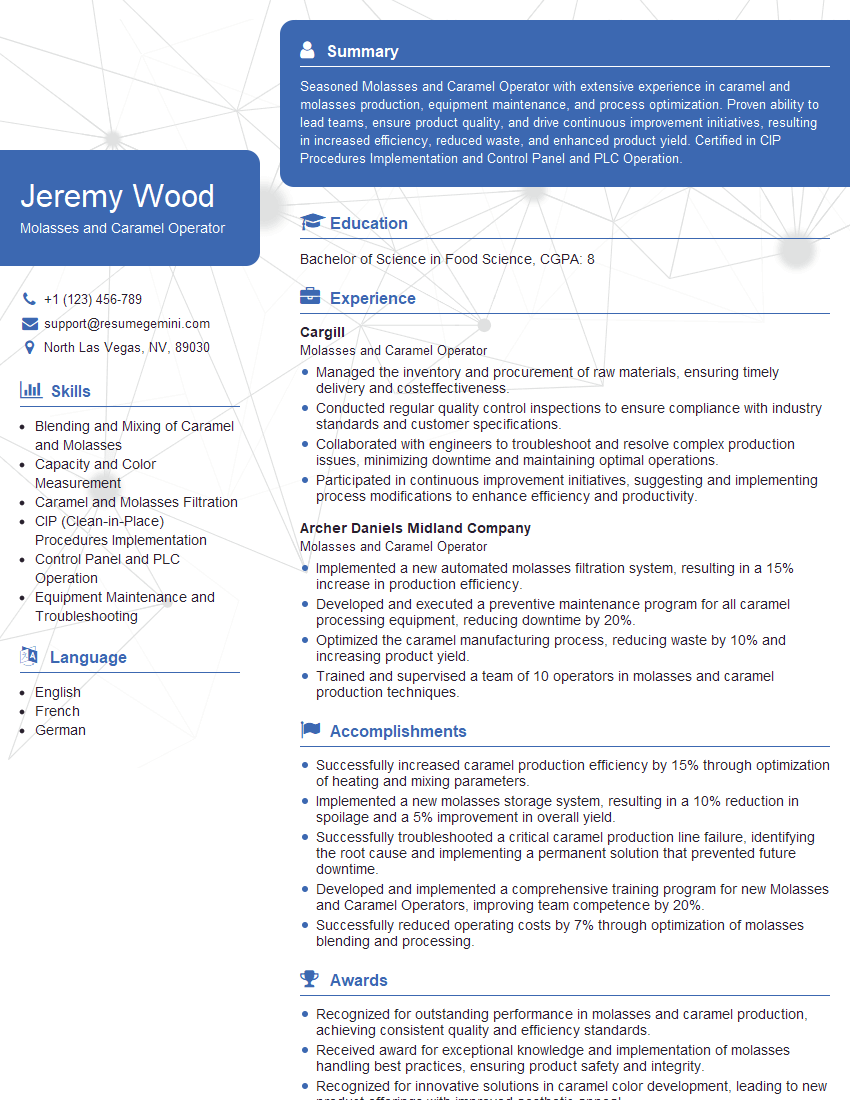

Jeremy Wood

Molasses and Caramel Operator

Summary

Seasoned Molasses and Caramel Operator with extensive experience in caramel and molasses production, equipment maintenance, and process optimization. Proven ability to lead teams, ensure product quality, and drive continuous improvement initiatives, resulting in increased efficiency, reduced waste, and enhanced product yield. Certified in CIP Procedures Implementation and Control Panel and PLC Operation.

Education

Bachelor of Science in Food Science

November 2016

Skills

- Blending and Mixing of Caramel and Molasses

- Capacity and Color Measurement

- Caramel and Molasses Filtration

- CIP (Clean-in-Place) Procedures Implementation

- Control Panel and PLC Operation

- Equipment Maintenance and Troubleshooting

Work Experience

Molasses and Caramel Operator

- Managed the inventory and procurement of raw materials, ensuring timely delivery and costeffectiveness.

- Conducted regular quality control inspections to ensure compliance with industry standards and customer specifications.

- Collaborated with engineers to troubleshoot and resolve complex production issues, minimizing downtime and maintaining optimal operations.

- Participated in continuous improvement initiatives, suggesting and implementing process modifications to enhance efficiency and productivity.

Molasses and Caramel Operator

- Implemented a new automated molasses filtration system, resulting in a 15% increase in production efficiency.

- Developed and executed a preventive maintenance program for all caramel processing equipment, reducing downtime by 20%.

- Optimized the caramel manufacturing process, reducing waste by 10% and increasing product yield.

- Trained and supervised a team of 10 operators in molasses and caramel production techniques.

Accomplishments

- Successfully increased caramel production efficiency by 15% through optimization of heating and mixing parameters.

- Implemented a new molasses storage system, resulting in a 10% reduction in spoilage and a 5% improvement in overall yield.

- Successfully troubleshooted a critical caramel production line failure, identifying the root cause and implementing a permanent solution that prevented future downtime.

- Developed and implemented a comprehensive training program for new Molasses and Caramel Operators, improving team competence by 20%.

- Successfully reduced operating costs by 7% through optimization of molasses blending and processing.

Awards

- Recognized for outstanding performance in molasses and caramel production, achieving consistent quality and efficiency standards.

- Received award for exceptional knowledge and implementation of molasses handling best practices, ensuring product safety and integrity.

- Recognized for innovative solutions in caramel color development, leading to new product offerings with improved aesthetic appeal.

- Received award for exceptional communication and teamwork skills, fostering a collaborative work environment.

Certificates

- Certified Production Technician (CPT)

- HACCP (Hazard Analysis and Critical Control Points) Certification

- ISO 22000 Food Safety Management System Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Molasses and Caramel Operator

- Highlight your knowledge of caramel and molasses production processes and techniques.

- Showcase your experience in equipment maintenance and troubleshooting.

- Quantify your accomplishments in terms of efficiency improvements, cost savings, or quality enhancements.

- Include industry-specific keywords such as CIP Procedures Implementation, Control Panel and PLC Operation, and HACCP principles.

Essential Experience Highlights for a Strong Molasses and Caramel Operator Resume

- Blending and mixing of caramel and molasses to achieve desired specifications

- Measuring capacity and color of caramel and molasses to ensure quality standards

- Filtration of caramel and molasses to remove impurities and ensure clarity

- Implementation of CIP (Clean-in-Place) procedures to maintain equipment hygiene

- Operation of control panels and PLCs to monitor and control production processes

- Maintenance and troubleshooting of caramel and molasses processing equipment

- Training and supervision of production team to ensure efficient and safe operations

Frequently Asked Questions (FAQ’s) For Molasses and Caramel Operator

What are the key skills required to be a successful Molasses and Caramel Operator?

Key skills include blending and mixing, capacity and color measurement, filtration, CIP procedures implementation, control panel and PLC operation, equipment maintenance and troubleshooting, and quality control.

What is the career path for a Molasses and Caramel Operator?

With experience and additional training, Molasses and Caramel Operators can advance to positions such as Production Supervisor, Quality Control Manager, or Plant Manager in the food processing industry.

What are the educational requirements for a Molasses and Caramel Operator?

Typically, a high school diploma or equivalent is required. Some employers may prefer candidates with a degree in food science, chemistry, or a related field.

What is the work environment of a Molasses and Caramel Operator?

Molasses and Caramel Operators typically work in food processing plants. They may work in hot, humid, and noisy environments and may be required to lift heavy objects.

What are the safety precautions that Molasses and Caramel Operators must follow?

Operators must wear appropriate protective gear, such as gloves, goggles, and respirators, and follow proper lockout/tagout procedures when working with equipment.

What is the role of a Molasses and Caramel Operator in quality control?

Molasses and Caramel Operators are responsible for conducting quality control inspections to ensure that products meet industry standards and customer specifications.

How can Molasses and Caramel Operators contribute to continuous improvement initiatives?

Operators can participate in brainstorming sessions, suggest process modifications, and implement changes to enhance efficiency and productivity.