Are you a seasoned Mold Closer seeking a new career path? Discover our professionally built Mold Closer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

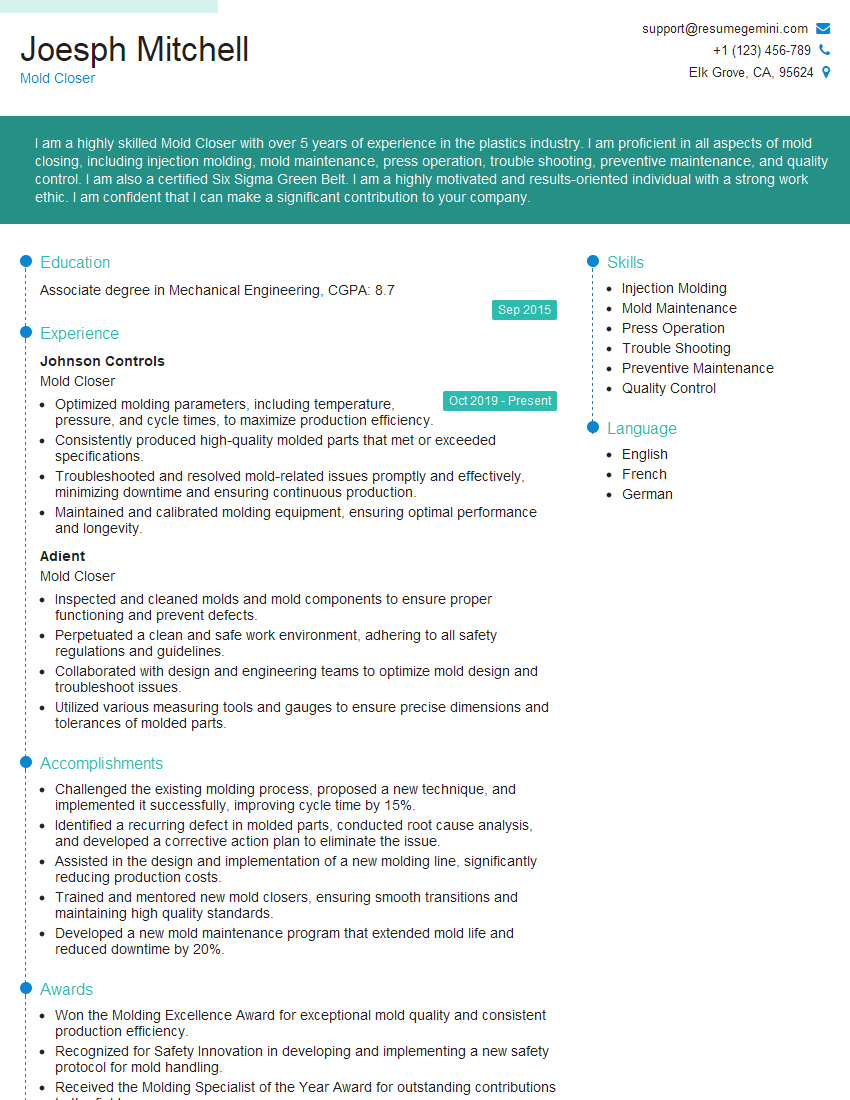

Joesph Mitchell

Mold Closer

Summary

I am a highly skilled Mold Closer with over 5 years of experience in the plastics industry. I am proficient in all aspects of mold closing, including injection molding, mold maintenance, press operation, trouble shooting, preventive maintenance, and quality control. I am also a certified Six Sigma Green Belt. I am a highly motivated and results-oriented individual with a strong work ethic. I am confident that I can make a significant contribution to your company.

Education

Associate degree in Mechanical Engineering

September 2015

Skills

- Injection Molding

- Mold Maintenance

- Press Operation

- Trouble Shooting

- Preventive Maintenance

- Quality Control

Work Experience

Mold Closer

- Optimized molding parameters, including temperature, pressure, and cycle times, to maximize production efficiency.

- Consistently produced high-quality molded parts that met or exceeded specifications.

- Troubleshooted and resolved mold-related issues promptly and effectively, minimizing downtime and ensuring continuous production.

- Maintained and calibrated molding equipment, ensuring optimal performance and longevity.

Mold Closer

- Inspected and cleaned molds and mold components to ensure proper functioning and prevent defects.

- Perpetuated a clean and safe work environment, adhering to all safety regulations and guidelines.

- Collaborated with design and engineering teams to optimize mold design and troubleshoot issues.

- Utilized various measuring tools and gauges to ensure precise dimensions and tolerances of molded parts.

Accomplishments

- Challenged the existing molding process, proposed a new technique, and implemented it successfully, improving cycle time by 15%.

- Identified a recurring defect in molded parts, conducted root cause analysis, and developed a corrective action plan to eliminate the issue.

- Assisted in the design and implementation of a new molding line, significantly reducing production costs.

- Trained and mentored new mold closers, ensuring smooth transitions and maintaining high quality standards.

- Developed a new mold maintenance program that extended mold life and reduced downtime by 20%.

Awards

- Won the Molding Excellence Award for exceptional mold quality and consistent production efficiency.

- Recognized for Safety Innovation in developing and implementing a new safety protocol for mold handling.

- Received the Molding Specialist of the Year Award for outstanding contributions to the field.

- Honored with the Employee of the Month award for exceptional teamwork and dedication.

Certificates

- Certified Molding Technician (CMT)

- Certified Plastics Technician (CPT)

- Six Sigma Green Belt

- ISO 9001 Lead Auditor

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Mold Closer

- Use strong action verbs in your resume.

- Quantify your accomplishments whenever possible.

- Highlight your skills and experience in the industry.

- Proofread your resume carefully before submitting it.

Essential Experience Highlights for a Strong Mold Closer Resume

- Operate and maintain injection molding machines.

- Set up and adjust molds.

- Troubleshoot and resolve production problems.

- Perform preventive maintenance on equipment.

- Inspect and test parts for quality.

- Follow safety procedures.

- Work effectively with a team.

Frequently Asked Questions (FAQ’s) For Mold Closer

What is the role of a Mold Closer?

A Mold Closer is responsible for operating and maintaining injection molding machines, setting up and adjusting molds, troubleshooting and resolving production problems, performing preventive maintenance on equipment, inspecting and testing parts for quality, following safety procedures, and working effectively with a team.

What are the qualifications for a Mold Closer?

A Mold Closer typically needs a high school diploma or equivalent, plus some experience in the plastics industry. Some employers may require an associate degree in Mechanical Engineering or a related field.

What are the skills required for a Mold Closer?

A Mold Closer typically needs skills in injection molding, mold maintenance, press operation, trouble shooting, preventive maintenance, and quality control. Some employers may also require certification in Six Sigma Green Belt.

What is the career outlook for a Mold Closer?

The career outlook for a Mold Closer is good. The demand for skilled Mold Closers is expected to grow as the plastics industry continues to expand.

What is the average salary for a Mold Closer?

The average salary for a Mold Closer is $25 per hour.

What are the benefits of being a Mold Closer?

Being a Mold Closer offers many benefits, including a competitive salary, good benefits, and the opportunity to work in a challenging and rewarding field.