Are you a seasoned Mold Forms Builder seeking a new career path? Discover our professionally built Mold Forms Builder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

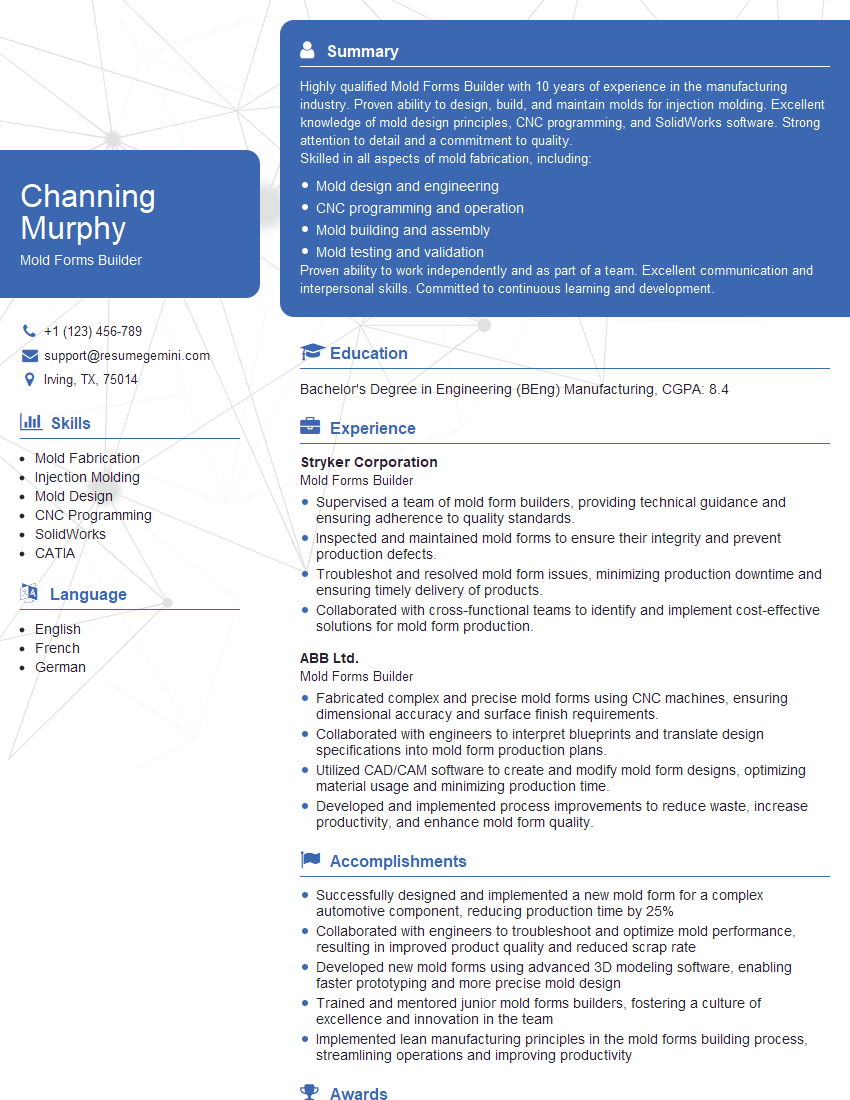

Channing Murphy

Mold Forms Builder

Summary

Highly qualified Mold Forms Builder with 10 years of experience in the manufacturing industry. Proven ability to design, build, and maintain molds for injection molding. Excellent knowledge of mold design principles, CNC programming, and SolidWorks software. Strong attention to detail and a commitment to quality.

Skilled in all aspects of mold fabrication, including:

- Mold design and engineering

- CNC programming and operation

- Mold building and assembly

- Mold testing and validation

Proven ability to work independently and as part of a team. Excellent communication and interpersonal skills. Committed to continuous learning and development.

Education

Bachelor’s Degree in Engineering (BEng) Manufacturing

April 2016

Skills

- Mold Fabrication

- Injection Molding

- Mold Design

- CNC Programming

- SolidWorks

- CATIA

Work Experience

Mold Forms Builder

- Supervised a team of mold form builders, providing technical guidance and ensuring adherence to quality standards.

- Inspected and maintained mold forms to ensure their integrity and prevent production defects.

- Troubleshot and resolved mold form issues, minimizing production downtime and ensuring timely delivery of products.

- Collaborated with cross-functional teams to identify and implement cost-effective solutions for mold form production.

Mold Forms Builder

- Fabricated complex and precise mold forms using CNC machines, ensuring dimensional accuracy and surface finish requirements.

- Collaborated with engineers to interpret blueprints and translate design specifications into mold form production plans.

- Utilized CAD/CAM software to create and modify mold form designs, optimizing material usage and minimizing production time.

- Developed and implemented process improvements to reduce waste, increase productivity, and enhance mold form quality.

Accomplishments

- Successfully designed and implemented a new mold form for a complex automotive component, reducing production time by 25%

- Collaborated with engineers to troubleshoot and optimize mold performance, resulting in improved product quality and reduced scrap rate

- Developed new mold forms using advanced 3D modeling software, enabling faster prototyping and more precise mold design

- Trained and mentored junior mold forms builders, fostering a culture of excellence and innovation in the team

- Implemented lean manufacturing principles in the mold forms building process, streamlining operations and improving productivity

Awards

- Received the Outstanding Mold Forms Builder Award for exceptional contributions to mold design and manufacturing

- Recognized as a Master Mold Forms Builder for innovative techniques and mentorship in mold design

- Won the National Mold Forms Builder Competition for exceptional mold design and problemsolving skills

- Received a Safety Award for maintaining an exemplary safety record in the mold forms building process

Certificates

- Certified Mold Designer

- Certified Toolmaker

- Certified Moldmaker

- Certified Manufacturing Engineer (CMfgE)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Mold Forms Builder

- Highlight your experience and skills in mold design, CNC programming, and SolidWorks.

- Showcase your knowledge of mold fabrication processes and quality standards.

- Quantify your accomplishments and provide specific examples of your work.

- Tailor your resume to each job you apply for, highlighting the skills and experience that are most relevant to the position.

Essential Experience Highlights for a Strong Mold Forms Builder Resume

- Design and develop molds for injection molding

- Program and operate CNC machines to create mold components

- Build and assemble molds according to specifications

- Test and validate molds to ensure they meet quality standards

- Maintain and repair molds as needed

- Stay up-to-date on the latest mold design and manufacturing technologies

- Work with engineers and other team members to develop and improve molds

Frequently Asked Questions (FAQ’s) For Mold Forms Builder

What is the role of a Mold Forms Builder?

A Mold Forms Builder is responsible for designing, building, and maintaining molds for injection molding. They work closely with engineers and other team members to develop and improve molds, and they ensure that molds meet quality standards.

What are the key skills required to be a successful Mold Forms Builder?

Key skills for a successful Mold Forms Builder include mold design, CNC programming, SolidWorks, mold fabrication, and quality control.

What are the career prospects for Mold Forms Builders?

Mold Forms Builders can advance to positions such as Mold Design Engineer, Mold Manufacturing Manager, or Quality Control Manager.

What is the job outlook for Mold Forms Builders?

The job outlook for Mold Forms Builders is expected to grow in the coming years due to the increasing demand for plastic products.

What are the educational requirements to become a Mold Forms Builder?

Most Mold Forms Builders have a Bachelor’s Degree in Engineering (BEng) Manufacturing or a related field.

What are the salary expectations for Mold Forms Builders?

The salary expectations for Mold Forms Builders vary depending on experience, location, and company size. However, the average salary for Mold Forms Builders is around $60,000 per year.