Are you a seasoned Mold Laminator seeking a new career path? Discover our professionally built Mold Laminator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

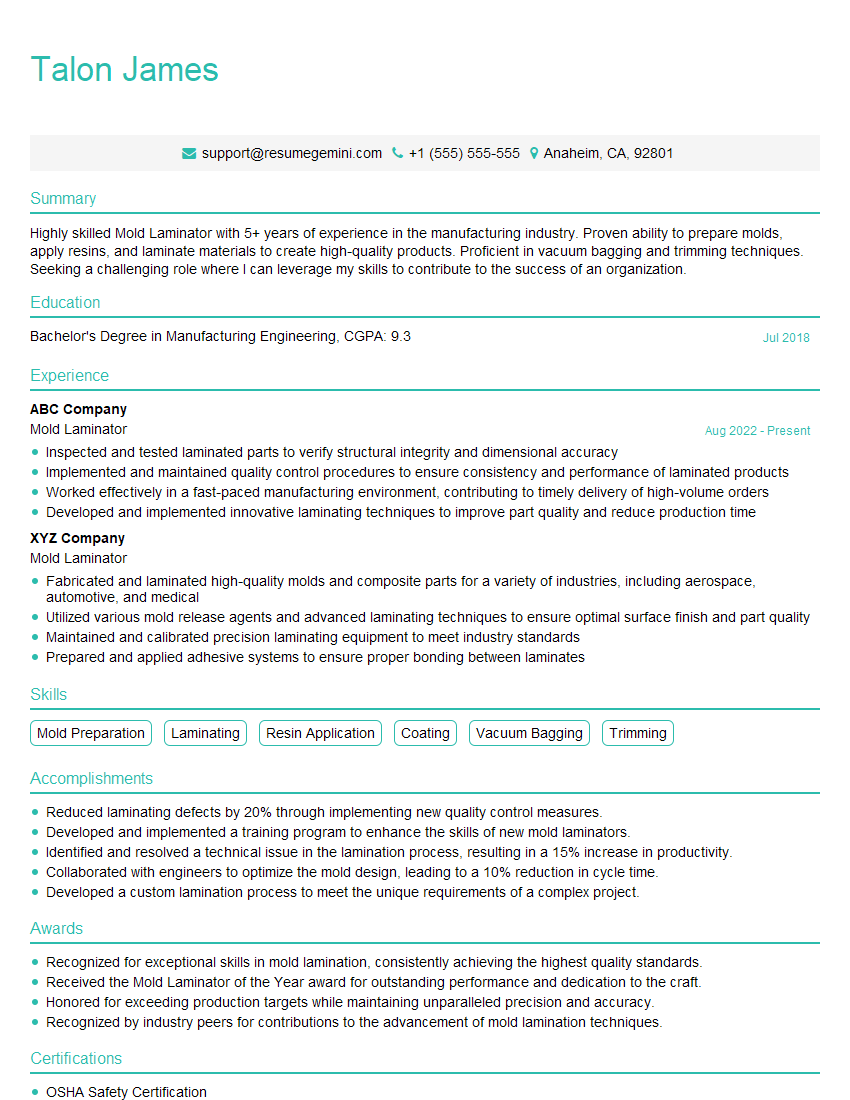

Talon James

Mold Laminator

Summary

Highly skilled Mold Laminator with 5+ years of experience in the manufacturing industry. Proven ability to prepare molds, apply resins, and laminate materials to create high-quality products. Proficient in vacuum bagging and trimming techniques. Seeking a challenging role where I can leverage my skills to contribute to the success of an organization.

Education

Bachelor’s Degree in Manufacturing Engineering

July 2018

Skills

- Mold Preparation

- Laminating

- Resin Application

- Coating

- Vacuum Bagging

- Trimming

Work Experience

Mold Laminator

- Inspected and tested laminated parts to verify structural integrity and dimensional accuracy

- Implemented and maintained quality control procedures to ensure consistency and performance of laminated products

- Worked effectively in a fast-paced manufacturing environment, contributing to timely delivery of high-volume orders

- Developed and implemented innovative laminating techniques to improve part quality and reduce production time

Mold Laminator

- Fabricated and laminated high-quality molds and composite parts for a variety of industries, including aerospace, automotive, and medical

- Utilized various mold release agents and advanced laminating techniques to ensure optimal surface finish and part quality

- Maintained and calibrated precision laminating equipment to meet industry standards

- Prepared and applied adhesive systems to ensure proper bonding between laminates

Accomplishments

- Reduced laminating defects by 20% through implementing new quality control measures.

- Developed and implemented a training program to enhance the skills of new mold laminators.

- Identified and resolved a technical issue in the lamination process, resulting in a 15% increase in productivity.

- Collaborated with engineers to optimize the mold design, leading to a 10% reduction in cycle time.

- Developed a custom lamination process to meet the unique requirements of a complex project.

Awards

- Recognized for exceptional skills in mold lamination, consistently achieving the highest quality standards.

- Received the Mold Laminator of the Year award for outstanding performance and dedication to the craft.

- Honored for exceeding production targets while maintaining unparalleled precision and accuracy.

- Recognized by industry peers for contributions to the advancement of mold lamination techniques.

Certificates

- OSHA Safety Certification

- Mold Laminating Certification

- American Society of Composites (ASC) Certification

- ISO 9001:2015 Quality Management System Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Mold Laminator

- Highlight your experience and skills in mold preparation, laminating, and resin application.

- Provide specific examples of projects you have worked on and the results you achieved.

- Quantify your accomplishments whenever possible, using numbers to demonstrate your impact.

- Tailor your resume to each job you apply for, highlighting the skills and experience that are most relevant to the requirements of the position.

Essential Experience Highlights for a Strong Mold Laminator Resume

- Prepare molds by cleaning and applying release agents.

- Laminate materials using resin, fiberglass, and other composites.

- Apply resins and coatings to molds and laminated surfaces.

- Operate vacuum bagging equipment to create a vacuum environment for curing.

- Trim and finish laminated products to meet specifications.

- Maintain a clean and organized work area.

- Follow safety protocols and wear appropriate protective gear.

Frequently Asked Questions (FAQ’s) For Mold Laminator

What are the duties of a Mold Laminator?

Mold Laminators prepare molds, apply resins, and laminate materials to create high-quality products. They are also responsible for operating vacuum bagging equipment and trimming and finishing laminated products.

What are the qualifications required to become a Mold Laminator?

A high school diploma or equivalent is typically required to become a Mold Laminator. Some employers may prefer candidates with a college degree in manufacturing engineering or a related field.

What is the work environment of a Mold Laminator like?

Mold Laminators typically work in manufacturing facilities. The work environment can be noisy and dusty, and Mold Laminators are required to wear protective gear, such as gloves, safety glasses, and respirators.

What are the career prospects for Mold Laminators?

Mold Laminators can advance to supervisory or management positions. They may also choose to specialize in a particular area of laminating, such as composite materials or metalworking.

What are the challenges faced by Mold Laminators?

Mold Laminators face a number of challenges, including working with hazardous materials, meeting deadlines, and maintaining a high level of quality.

What are the personal qualities of a successful Mold Laminator?

Successful Mold Laminators are typically detail-oriented, have strong problem-solving skills, and are able to work independently and as part of a team.