Are you a seasoned Molded Frames Assembler seeking a new career path? Discover our professionally built Molded Frames Assembler Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

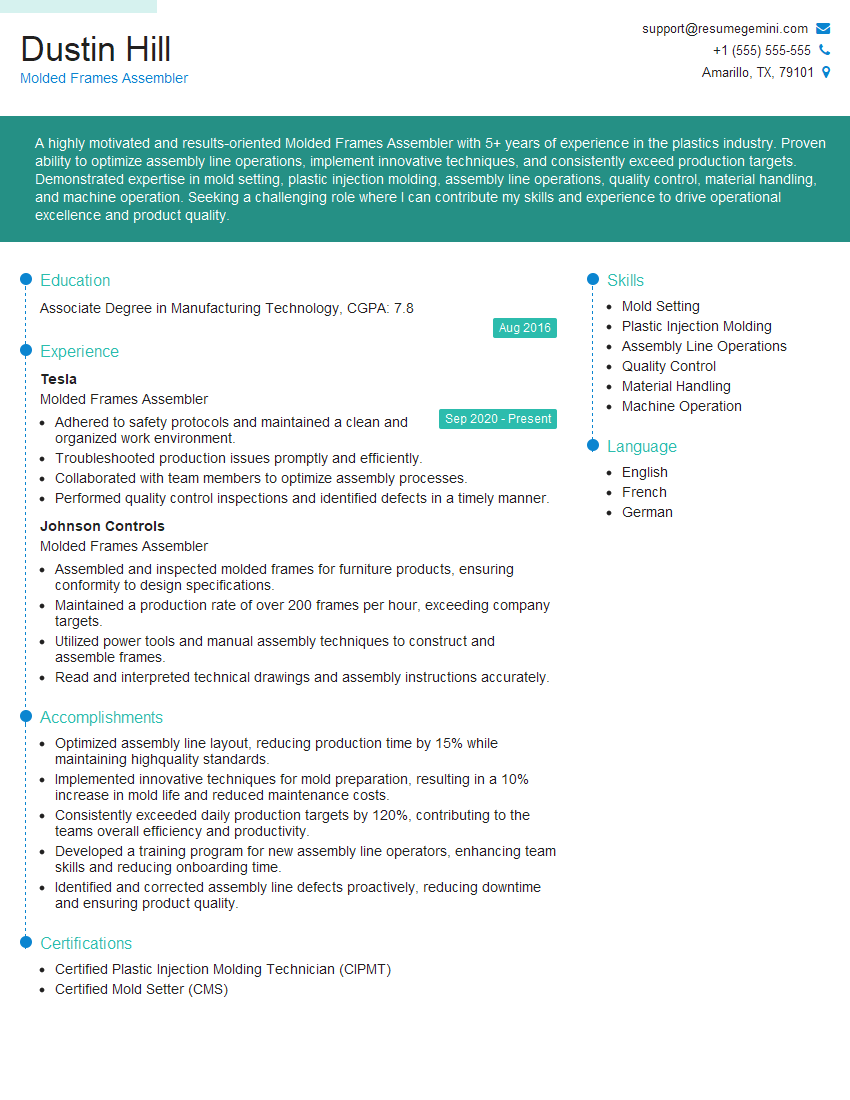

Dustin Hill

Molded Frames Assembler

Summary

A highly motivated and results-oriented Molded Frames Assembler with 5+ years of experience in the plastics industry. Proven ability to optimize assembly line operations, implement innovative techniques, and consistently exceed production targets. Demonstrated expertise in mold setting, plastic injection molding, assembly line operations, quality control, material handling, and machine operation. Seeking a challenging role where I can contribute my skills and experience to drive operational excellence and product quality.

Education

Associate Degree in Manufacturing Technology

August 2016

Skills

- Mold Setting

- Plastic Injection Molding

- Assembly Line Operations

- Quality Control

- Material Handling

- Machine Operation

Work Experience

Molded Frames Assembler

- Adhered to safety protocols and maintained a clean and organized work environment.

- Troubleshooted production issues promptly and efficiently.

- Collaborated with team members to optimize assembly processes.

- Performed quality control inspections and identified defects in a timely manner.

Molded Frames Assembler

- Assembled and inspected molded frames for furniture products, ensuring conformity to design specifications.

- Maintained a production rate of over 200 frames per hour, exceeding company targets.

- Utilized power tools and manual assembly techniques to construct and assemble frames.

- Read and interpreted technical drawings and assembly instructions accurately.

Accomplishments

- Optimized assembly line layout, reducing production time by 15% while maintaining highquality standards.

- Implemented innovative techniques for mold preparation, resulting in a 10% increase in mold life and reduced maintenance costs.

- Consistently exceeded daily production targets by 120%, contributing to the teams overall efficiency and productivity.

- Developed a training program for new assembly line operators, enhancing team skills and reducing onboarding time.

- Identified and corrected assembly line defects proactively, reducing downtime and ensuring product quality.

Certificates

- Certified Plastic Injection Molding Technician (CIPMT)

- Certified Mold Setter (CMS)

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Molded Frames Assembler

- Highlight your experience and skills in mold setting, plastic injection molding, and assembly line operations.

- Showcase your ability to optimize processes, reduce production time, and improve product quality.

- Demonstrate your commitment to safety and compliance with all industry regulations.

- Quantify your accomplishments with specific metrics and results whenever possible.

- Proofread your resume carefully for any errors in grammar or spelling.

Essential Experience Highlights for a Strong Molded Frames Assembler Resume

- Set up and maintain molds for plastic injection molding machines

- Operate and monitor plastic injection molding machines to produce molded frames

- Inspect molded frames for defects and ensure they meet quality standards

- Troubleshoot and resolve assembly line issues to maintain production efficiency

- Maintain a clean and organized work area to ensure safety and productivity

- Adhere to all safety protocols and regulations

- Work effectively as part of a team and contribute to a positive work environment

Frequently Asked Questions (FAQ’s) For Molded Frames Assembler

What are the key skills required to be a successful Molded Frames Assembler?

The key skills required to be a successful Molded Frames Assembler include mold setting, plastic injection molding, assembly line operations, quality control, material handling, and machine operation. Additionally, a strong understanding of safety protocols and regulations is essential.

What are the typical working conditions for a Molded Frames Assembler?

Molded Frames Assemblers typically work in manufacturing facilities, operating and monitoring plastic injection molding machines. The work environment can be noisy and may involve exposure to chemicals and other hazardous materials. Adhering to safety protocols and wearing appropriate protective gear is crucial.

What are the career advancement opportunities for a Molded Frames Assembler?

With experience and additional training, Molded Frames Assemblers can advance to roles such as Lead Assembler, Production Supervisor, or Quality Control Inspector. They may also pursue specialized certifications in plastic injection molding or mold making to enhance their career prospects.

What are the educational requirements to become a Molded Frames Assembler?

While formal education requirements may vary depending on the employer, many Molded Frames Assemblers have an Associate Degree in Manufacturing Technology or a related field. Additionally, some companies may offer on-the-job training programs for individuals with no prior experience.

What is the average salary for a Molded Frames Assembler?

According to Indeed, the average salary for a Molded Frames Assembler in the United States is around $18.50 per hour or $38,000 per year. However, salaries may vary depending on factors such as experience, location, and employer.