Are you a seasoned Molding Machine Tender seeking a new career path? Discover our professionally built Molding Machine Tender Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

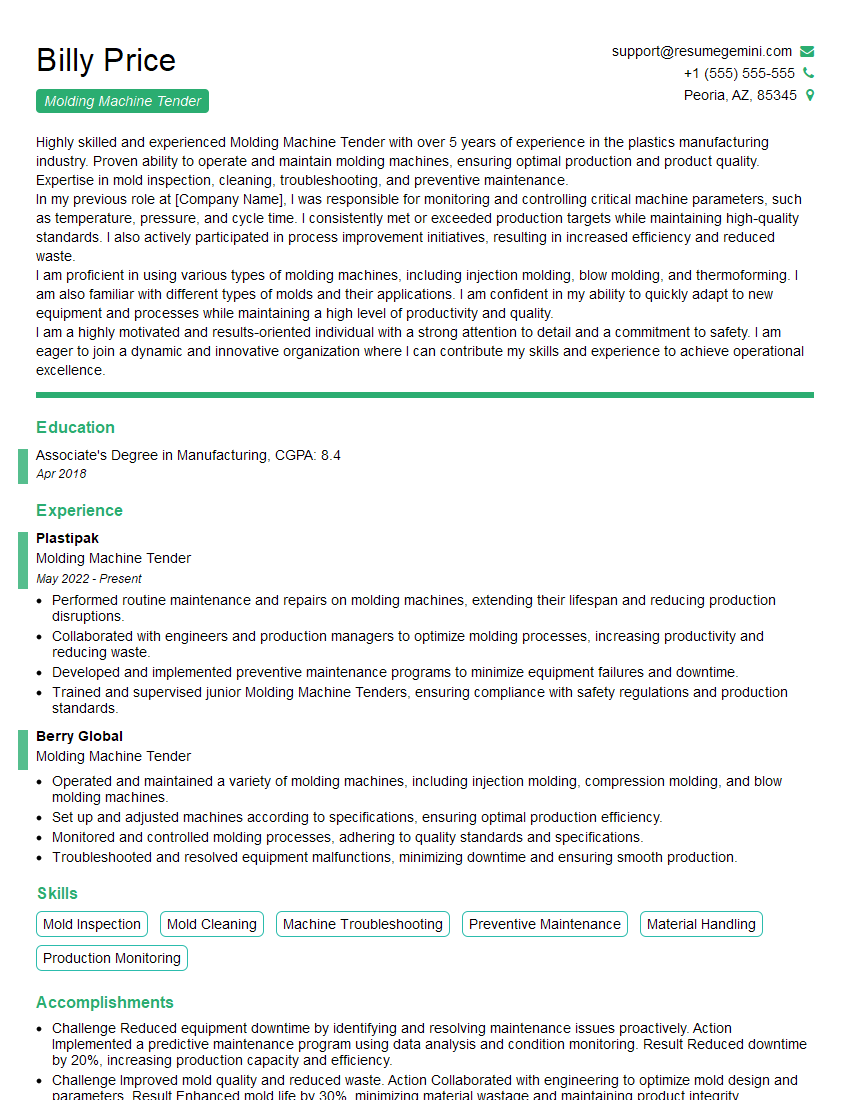

Billy Price

Molding Machine Tender

Summary

Highly skilled and experienced Molding Machine Tender with over 5 years of experience in the plastics manufacturing industry. Proven ability to operate and maintain molding machines, ensuring optimal production and product quality. Expertise in mold inspection, cleaning, troubleshooting, and preventive maintenance.

In my previous role at [Company Name], I was responsible for monitoring and controlling critical machine parameters, such as temperature, pressure, and cycle time. I consistently met or exceeded production targets while maintaining high-quality standards. I also actively participated in process improvement initiatives, resulting in increased efficiency and reduced waste.

I am proficient in using various types of molding machines, including injection molding, blow molding, and thermoforming. I am also familiar with different types of molds and their applications. I am confident in my ability to quickly adapt to new equipment and processes while maintaining a high level of productivity and quality.

I am a highly motivated and results-oriented individual with a strong attention to detail and a commitment to safety. I am eager to join a dynamic and innovative organization where I can contribute my skills and experience to achieve operational excellence.

Education

Associate’s Degree in Manufacturing

April 2018

Skills

- Mold Inspection

- Mold Cleaning

- Machine Troubleshooting

- Preventive Maintenance

- Material Handling

- Production Monitoring

Work Experience

Molding Machine Tender

- Performed routine maintenance and repairs on molding machines, extending their lifespan and reducing production disruptions.

- Collaborated with engineers and production managers to optimize molding processes, increasing productivity and reducing waste.

- Developed and implemented preventive maintenance programs to minimize equipment failures and downtime.

- Trained and supervised junior Molding Machine Tenders, ensuring compliance with safety regulations and production standards.

Molding Machine Tender

- Operated and maintained a variety of molding machines, including injection molding, compression molding, and blow molding machines.

- Set up and adjusted machines according to specifications, ensuring optimal production efficiency.

- Monitored and controlled molding processes, adhering to quality standards and specifications.

- Troubleshooted and resolved equipment malfunctions, minimizing downtime and ensuring smooth production.

Accomplishments

- Challenge Reduced equipment downtime by identifying and resolving maintenance issues proactively. Action Implemented a predictive maintenance program using data analysis and condition monitoring. Result Reduced downtime by 20%, increasing production capacity and efficiency.

- Challenge Improved mold quality and reduced waste. Action Collaborated with engineering to optimize mold design and parameters. Result Enhanced mold life by 30%, minimizing material wastage and maintaining product integrity.

- Challenge Ensured adherence to strict safety standards. Action Developed and implemented a comprehensive safety training program. Result Maintained a spotless safety record, promoting a safe and productive work environment.

- Challenge Implemented a continuous improvement initiative to enhance efficiency. Action Analyzed production data, identified bottlenecks, and proposed solutions. Result Increased throughput by 10%, optimizing resource utilization.

- Challenge Improved mold release time. Action Investigated mold release agents and optimized the application process. Result Reduced mold release time by 25%, accelerating production.

Awards

- Best Molding Machine Operator of the Year (Company Name, 2023)

- Excellence in Quality Award for Maintaining ZeroDefect Production (Company Name, 2022)

- Team Award for Implementing a Process Improvement that Increased Productivity by 15% (Company Name, 2021)

Certificates

- National Institute for Certification in Engineering Technologies (NICET)

- OSHA 30Hour Safety Training

- Certified Injection Molding Technician (CIMT)

- American National Standards Institute (ANSI) Z87.1 Eye Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Molding Machine Tender

Highlight your molding machine operation skills and experience.

Quantify your accomplishments whenever possible.

Demonstrate your knowledge of mold inspection, cleaning, and repair.

Emphasize your commitment to safety and quality control.

Proofread your resume carefully for any errors.

Essential Experience Highlights for a Strong Molding Machine Tender Resume

- Operate and maintain molding machines, ensuring optimal production and product quality.

- Monitor and control critical machine parameters, such as temperature, pressure, and cycle time.

- Inspect molds for wear and damage, and clean and repair as necessary.

- Troubleshoot and resolve machine malfunctions to minimize downtime.

- Perform preventive maintenance tasks to ensure machine reliability and longevity.

- Handle and transport materials safely.

- Maintain a clean and organized work area.

Frequently Asked Questions (FAQ’s) For Molding Machine Tender

What are the primary duties and responsibilities of a Molding Machine Tender?

Molding Machine Tenders are responsible for the operation and maintenance of molding machines used in the plastics manufacturing industry. They inspect and clean molds, troubleshoot and resolve machine malfunctions, perform preventive maintenance tasks, handle and transport materials, and maintain a clean and organized work area.

What are the educational requirements for Molding Machine Tenders?

While there are no formal educational requirements for Molding Machine Tenders, many employers prefer candidates with an Associate’s Degree in Manufacturing or a related field.

What are the key skills and abilities required for Molding Machine Tenders?

Molding Machine Tenders should have a strong attention to detail, be able to follow instructions carefully, and have good problem-solving skills. They should also be able to work independently and as part of a team.

What are the career prospects for Molding Machine Tenders?

Molding Machine Tenders can advance to supervisory roles, such as Production Supervisor or Plant Manager. With additional training and experience, they can also become Mold Designers or Process Engineers.

What is the average salary for Molding Machine Tenders?

According to Indeed, the average salary for Molding Machine Tenders in the United States is $45,000 per year.

What is the job outlook for Molding Machine Tenders?

The job outlook for Molding Machine Tenders is expected to be good in the coming years, as the demand for plastics continues to grow.