Are you a seasoned Mulling Machine Operator seeking a new career path? Discover our professionally built Mulling Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

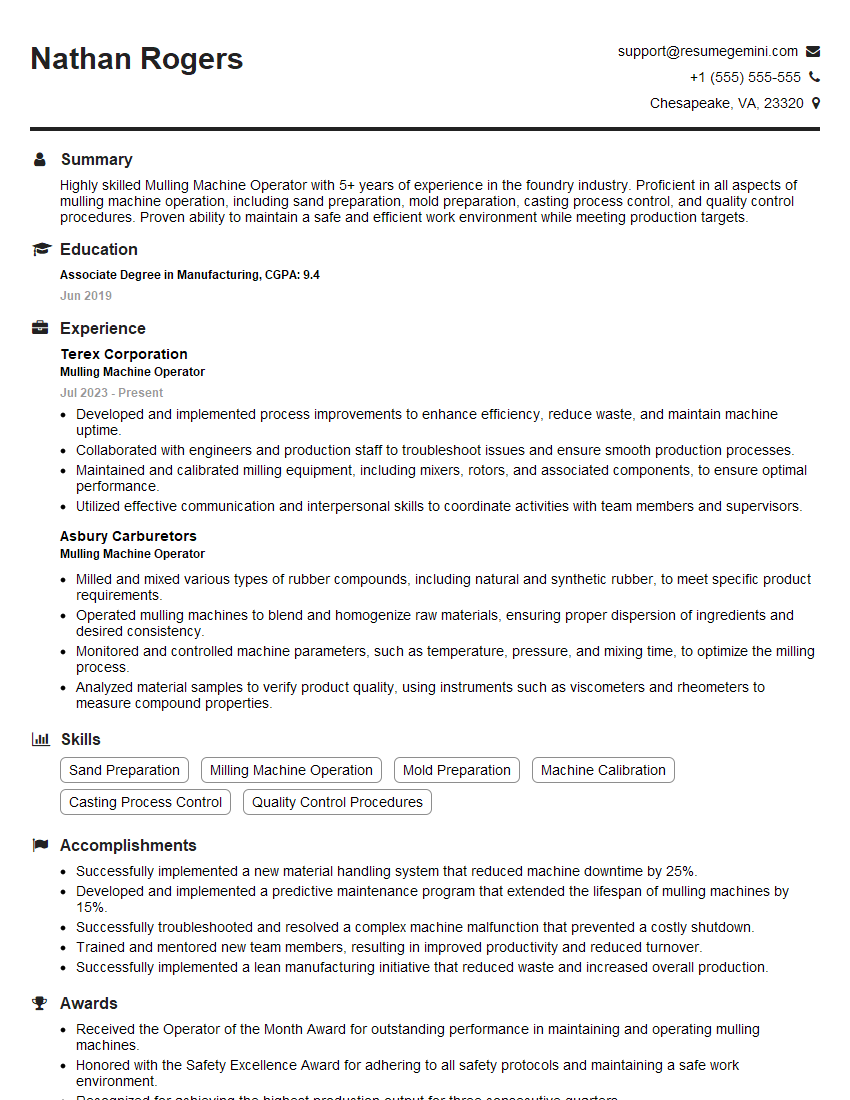

Nathan Rogers

Mulling Machine Operator

Summary

Highly skilled Mulling Machine Operator with 5+ years of experience in the foundry industry. Proficient in all aspects of mulling machine operation, including sand preparation, mold preparation, casting process control, and quality control procedures. Proven ability to maintain a safe and efficient work environment while meeting production targets.

Education

Associate Degree in Manufacturing

June 2019

Skills

- Sand Preparation

- Milling Machine Operation

- Mold Preparation

- Machine Calibration

- Casting Process Control

- Quality Control Procedures

Work Experience

Mulling Machine Operator

- Developed and implemented process improvements to enhance efficiency, reduce waste, and maintain machine uptime.

- Collaborated with engineers and production staff to troubleshoot issues and ensure smooth production processes.

- Maintained and calibrated milling equipment, including mixers, rotors, and associated components, to ensure optimal performance.

- Utilized effective communication and interpersonal skills to coordinate activities with team members and supervisors.

Mulling Machine Operator

- Milled and mixed various types of rubber compounds, including natural and synthetic rubber, to meet specific product requirements.

- Operated mulling machines to blend and homogenize raw materials, ensuring proper dispersion of ingredients and desired consistency.

- Monitored and controlled machine parameters, such as temperature, pressure, and mixing time, to optimize the milling process.

- Analyzed material samples to verify product quality, using instruments such as viscometers and rheometers to measure compound properties.

Accomplishments

- Successfully implemented a new material handling system that reduced machine downtime by 25%.

- Developed and implemented a predictive maintenance program that extended the lifespan of mulling machines by 15%.

- Successfully troubleshooted and resolved a complex machine malfunction that prevented a costly shutdown.

- Trained and mentored new team members, resulting in improved productivity and reduced turnover.

- Successfully implemented a lean manufacturing initiative that reduced waste and increased overall production.

Awards

- Received the Operator of the Month Award for outstanding performance in maintaining and operating mulling machines.

- Honored with the Safety Excellence Award for adhering to all safety protocols and maintaining a safe work environment.

- Recognized for achieving the highest production output for three consecutive quarters.

- Awarded the Employee of the Year title for exceptional contributions to the team and department.

Certificates

- Certified Mulling Machine Operator

- Certified Lean Manufacturing Specialist

- Certified Six Sigma Black Belt

- Certified Quality Manager

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Mulling Machine Operator

- Quantify your accomplishments whenever possible.

- Use action verbs to describe your skills and responsibilities.

- Highlight your experience with specific types of equipment or processes.

- Proofread your resume carefully for errors.

- Tailor your resume to each job you apply for.

Essential Experience Highlights for a Strong Mulling Machine Operator Resume

- Prepare sand to the required specifications for casting.

- Operate mulling machine to mix sand, binders, and additives.

- Set up and prepare molds for casting.

- Calibrate and maintain mulling machine to ensure optimal performance.

- Monitor casting process to ensure quality and prevent defects.

- Conduct quality control checks on castings to verify conformance to specifications.

- Maintain a clean and organized work area.

Frequently Asked Questions (FAQ’s) For Mulling Machine Operator

What is a Mulling Machine Operator?

A Mulling Machine Operator is responsible for operating a mulling machine, which is used to mix sand, binders, and additives to create a mold for casting. They also prepare sand to the required specifications, set up and prepare molds, calibrate and maintain the mulling machine, monitor the casting process, and conduct quality control checks on castings.

What are the qualifications for a Mulling Machine Operator?

Most Mulling Machine Operators have an Associate Degree in Manufacturing or a related field. They also have experience operating a mulling machine and knowledge of casting processes and quality control procedures.

What are the skills required for a Mulling Machine Operator?

Mulling Machine Operators need to have strong mechanical skills and be able to operate and maintain a variety of equipment. They also need to be able to read and interpret blueprints and work with precision.

What is the work environment of a Mulling Machine Operator?

Mulling Machine Operators typically work in a foundry or manufacturing plant. They may be exposed to dust, noise, and heat. They also may need to work overtime or on weekends to meet production deadlines.

What is the salary of a Mulling Machine Operator?

The salary of a Mulling Machine Operator can vary depending on their experience, location, and employer. According to Indeed, the average salary for a Mulling Machine Operator in the United States is $22.50 per hour.

What is the job outlook for Mulling Machine Operators?

The job outlook for Mulling Machine Operators is expected to be good over the next few years. The demand for castings is expected to increase as the manufacturing sector continues to grow.