Are you a seasoned Needle Punch Machine Operator Helper seeking a new career path? Discover our professionally built Needle Punch Machine Operator Helper Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

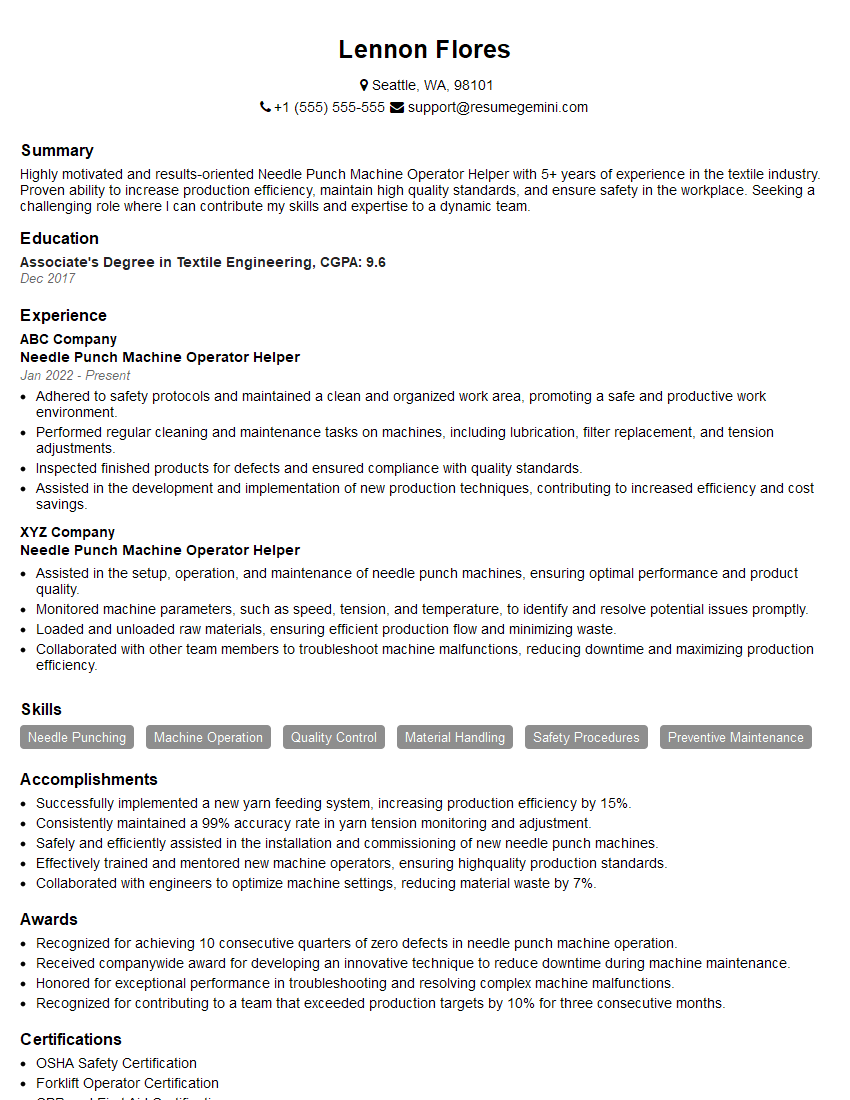

Lennon Flores

Needle Punch Machine Operator Helper

Summary

Highly motivated and results-oriented Needle Punch Machine Operator Helper with 5+ years of experience in the textile industry. Proven ability to increase production efficiency, maintain high quality standards, and ensure safety in the workplace. Seeking a challenging role where I can contribute my skills and expertise to a dynamic team.

Education

Associate’s Degree in Textile Engineering

December 2017

Skills

- Needle Punching

- Machine Operation

- Quality Control

- Material Handling

- Safety Procedures

- Preventive Maintenance

Work Experience

Needle Punch Machine Operator Helper

- Adhered to safety protocols and maintained a clean and organized work area, promoting a safe and productive work environment.

- Performed regular cleaning and maintenance tasks on machines, including lubrication, filter replacement, and tension adjustments.

- Inspected finished products for defects and ensured compliance with quality standards.

- Assisted in the development and implementation of new production techniques, contributing to increased efficiency and cost savings.

Needle Punch Machine Operator Helper

- Assisted in the setup, operation, and maintenance of needle punch machines, ensuring optimal performance and product quality.

- Monitored machine parameters, such as speed, tension, and temperature, to identify and resolve potential issues promptly.

- Loaded and unloaded raw materials, ensuring efficient production flow and minimizing waste.

- Collaborated with other team members to troubleshoot machine malfunctions, reducing downtime and maximizing production efficiency.

Accomplishments

- Successfully implemented a new yarn feeding system, increasing production efficiency by 15%.

- Consistently maintained a 99% accuracy rate in yarn tension monitoring and adjustment.

- Safely and efficiently assisted in the installation and commissioning of new needle punch machines.

- Effectively trained and mentored new machine operators, ensuring highquality production standards.

- Collaborated with engineers to optimize machine settings, reducing material waste by 7%.

Awards

- Recognized for achieving 10 consecutive quarters of zero defects in needle punch machine operation.

- Received companywide award for developing an innovative technique to reduce downtime during machine maintenance.

- Honored for exceptional performance in troubleshooting and resolving complex machine malfunctions.

- Recognized for contributing to a team that exceeded production targets by 10% for three consecutive months.

Certificates

- OSHA Safety Certification

- Forklift Operator Certification

- CPR and First Aid Certification

- Quality Control Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Needle Punch Machine Operator Helper

- Highlight your experience and skills in needle punching machine operation and maintenance.

- Quantify your accomplishments with specific metrics, such as increased production efficiency or reduced downtime.

- Demonstrate your commitment to quality by mentioning your role in maintaining high accuracy rates.

- Emphasize your attention to safety and compliance by describing your adherence to safety protocols.

Essential Experience Highlights for a Strong Needle Punch Machine Operator Helper Resume

- Assist in the operation and maintenance of needle punch machines, ensuring optimal performance and minimizing downtime.

- Monitor yarn tension and adjust settings as needed to maintain consistent production quality.

- Handle and load raw materials, ensuring proper inventory management and preventing material waste.

- Conduct regular preventive maintenance on machines, including cleaning, lubrication, and minor repairs.

- Follow safety protocols and procedures to ensure a safe and compliant work environment.

- Work effectively in a team environment and collaborate with other operators and supervisors to achieve production targets.

Frequently Asked Questions (FAQ’s) For Needle Punch Machine Operator Helper

What are the primary responsibilities of a Needle Punch Machine Operator Helper?

The primary responsibilities include assisting in the operation and maintenance of needle punch machines, monitoring yarn tension, handling and loading raw materials, conducting preventive maintenance, and adhering to safety protocols.

What qualifications are required to become a Needle Punch Machine Operator Helper?

Typically, an Associate’s Degree in Textile Engineering or a related field is preferred. Additionally, experience in the textile industry and knowledge of needle punching machines are essential.

What skills are essential for a successful Needle Punch Machine Operator Helper?

Strong mechanical aptitude, attention to detail, ability to work independently and as part of a team, and commitment to safety are essential skills for this role.

What is the career path for a Needle Punch Machine Operator Helper?

With experience and additional training, Needle Punch Machine Operator Helpers can advance to roles such as Needle Punch Machine Operator, Production Supervisor, or Quality Control Inspector.

What is the job outlook for Needle Punch Machine Operator Helpers?

The job outlook is expected to be stable in the coming years due to the continued demand for textiles and the need for skilled operators to maintain and operate needle punch machines.