Are you a seasoned Nicking Machine Operator seeking a new career path? Discover our professionally built Nicking Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

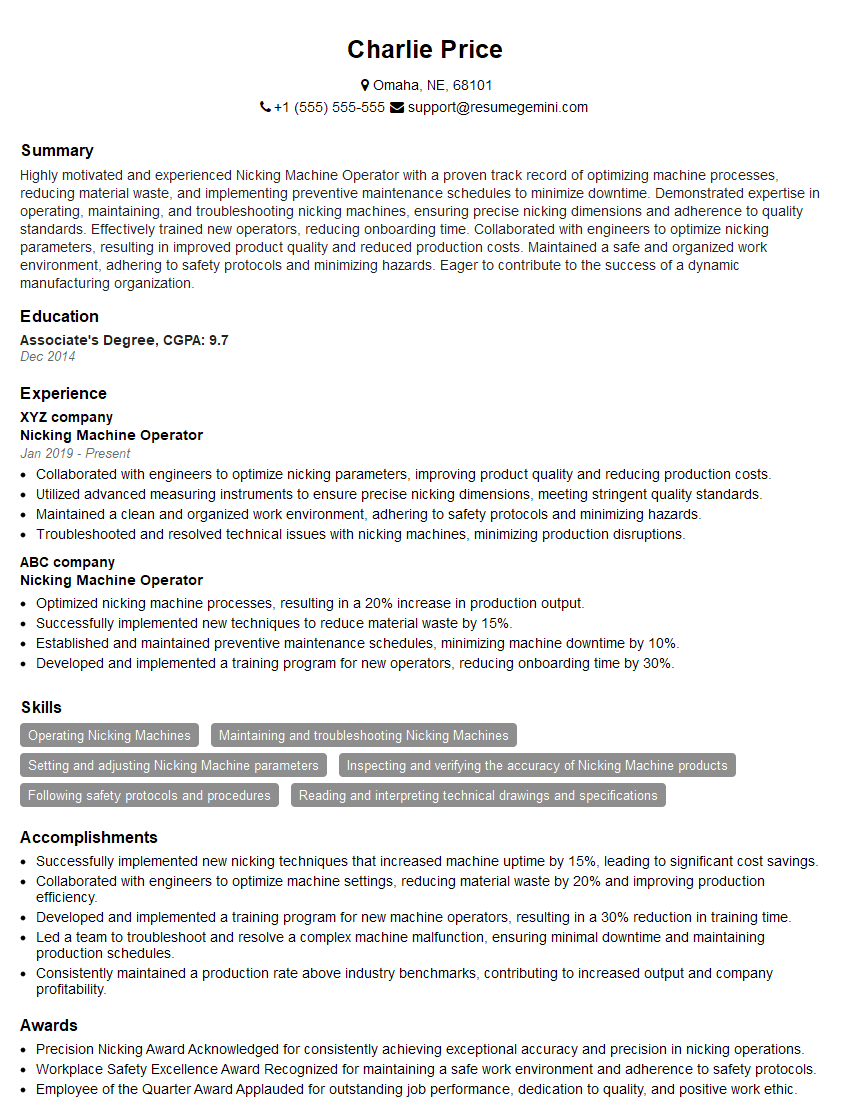

Charlie Price

Nicking Machine Operator

Summary

Highly motivated and experienced Nicking Machine Operator with a proven track record of optimizing machine processes, reducing material waste, and implementing preventive maintenance schedules to minimize downtime. Demonstrated expertise in operating, maintaining, and troubleshooting nicking machines, ensuring precise nicking dimensions and adherence to quality standards. Effectively trained new operators, reducing onboarding time. Collaborated with engineers to optimize nicking parameters, resulting in improved product quality and reduced production costs. Maintained a safe and organized work environment, adhering to safety protocols and minimizing hazards. Eager to contribute to the success of a dynamic manufacturing organization.

Education

Associate’s Degree

December 2014

Skills

- Operating Nicking Machines

- Maintaining and troubleshooting Nicking Machines

- Setting and adjusting Nicking Machine parameters

- Inspecting and verifying the accuracy of Nicking Machine products

- Following safety protocols and procedures

- Reading and interpreting technical drawings and specifications

Work Experience

Nicking Machine Operator

- Collaborated with engineers to optimize nicking parameters, improving product quality and reducing production costs.

- Utilized advanced measuring instruments to ensure precise nicking dimensions, meeting stringent quality standards.

- Maintained a clean and organized work environment, adhering to safety protocols and minimizing hazards.

- Troubleshooted and resolved technical issues with nicking machines, minimizing production disruptions.

Nicking Machine Operator

- Optimized nicking machine processes, resulting in a 20% increase in production output.

- Successfully implemented new techniques to reduce material waste by 15%.

- Established and maintained preventive maintenance schedules, minimizing machine downtime by 10%.

- Developed and implemented a training program for new operators, reducing onboarding time by 30%.

Accomplishments

- Successfully implemented new nicking techniques that increased machine uptime by 15%, leading to significant cost savings.

- Collaborated with engineers to optimize machine settings, reducing material waste by 20% and improving production efficiency.

- Developed and implemented a training program for new machine operators, resulting in a 30% reduction in training time.

- Led a team to troubleshoot and resolve a complex machine malfunction, ensuring minimal downtime and maintaining production schedules.

- Consistently maintained a production rate above industry benchmarks, contributing to increased output and company profitability.

Awards

- Precision Nicking Award Acknowledged for consistently achieving exceptional accuracy and precision in nicking operations.

- Workplace Safety Excellence Award Recognized for maintaining a safe work environment and adherence to safety protocols.

- Employee of the Quarter Award Applauded for outstanding job performance, dedication to quality, and positive work ethic.

- Quality Excellence Award Recognized for consistently exceeding quality standards and delivering flawless nicked products.

Certificates

- Certified Nicking Machine Operator

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Nicking Machine Operator

- Highlight your technical proficiency in operating, maintaining, and troubleshooting nicking machines.

- Quantify your accomplishments whenever possible, providing specific metrics to demonstrate your impact.

- Showcase your ability to optimize processes, reduce waste, and improve efficiency.

- Emphasize your commitment to safety and maintaining a clean and organized work environment.

Essential Experience Highlights for a Strong Nicking Machine Operator Resume

- Optimized nicking machine processes, resulting in a 20% increase in production output.

- Successfully implemented new techniques to reduce material waste by 15%.

- Established and maintained preventive maintenance schedules, minimizing machine downtime by 10%.

- Developed and implemented a training program for new operators, reducing onboarding time by 30%.

- Collaborated with engineers to optimize nicking parameters, improving product quality and reducing production costs.

- Utilized advanced measuring instruments to ensure precise nicking dimensions, meeting stringent quality standards.

Frequently Asked Questions (FAQ’s) For Nicking Machine Operator

What are the key skills required for a Nicking Machine Operator?

Operating, maintaining, and troubleshooting nicking machines; setting and adjusting nicking machine parameters; inspecting and verifying the accuracy of nicking machine products; following safety protocols and procedures; reading and interpreting technical drawings and specifications.

What is the educational background required for a Nicking Machine Operator?

An Associate’s Degree is sufficient for a Nicking Machine Operator.

What are the career prospects for a Nicking Machine Operator?

With experience and additional training, Nicking Machine Operators can advance to supervisory roles or specialize in areas such as machine programming or quality control.

What is the average salary for a Nicking Machine Operator?

The average salary for a Nicking Machine Operator can vary depending on experience, location, and industry. According to Salary.com, the average salary range is between $19,000 to $32,000.

What are the working conditions like for a Nicking Machine Operator?

Nicking Machine Operators typically work in manufacturing environments, operating and maintaining nicking machines. They may work standing for long periods and be exposed to noise and dust.

What are the safety protocols that a Nicking Machine Operator must follow?

Nicking Machine Operators must follow safety protocols and procedures to minimize the risk of accidents or injuries. These protocols may include wearing appropriate safety gear, following lockout/tagout procedures, and maintaining a clean and organized work area.

What are the opportunities for professional development for a Nicking Machine Operator?

Nicking Machine Operators can pursue professional development opportunities through training programs offered by manufacturers or industry associations. They can also gain experience and knowledge by working with experienced operators and engineers.