Are you a seasoned Nipping Machine Operator seeking a new career path? Discover our professionally built Nipping Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

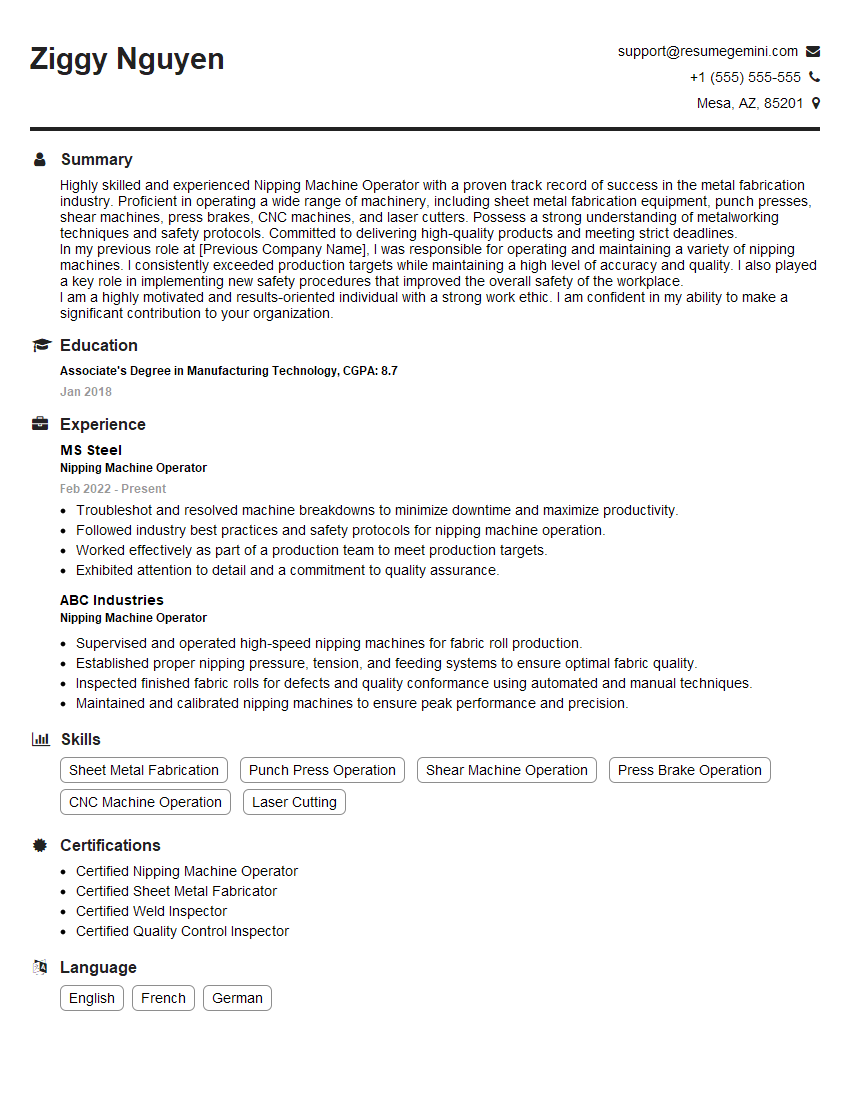

Ziggy Nguyen

Nipping Machine Operator

Summary

Highly skilled and experienced Nipping Machine Operator with a proven track record of success in the metal fabrication industry. Proficient in operating a wide range of machinery, including sheet metal fabrication equipment, punch presses, shear machines, press brakes, CNC machines, and laser cutters. Possess a strong understanding of metalworking techniques and safety protocols. Committed to delivering high-quality products and meeting strict deadlines.

In my previous role at [Previous Company Name], I was responsible for operating and maintaining a variety of nipping machines. I consistently exceeded production targets while maintaining a high level of accuracy and quality. I also played a key role in implementing new safety procedures that improved the overall safety of the workplace.

I am a highly motivated and results-oriented individual with a strong work ethic. I am confident in my ability to make a significant contribution to your organization.

Education

Associate’s Degree in Manufacturing Technology

January 2018

Skills

- Sheet Metal Fabrication

- Punch Press Operation

- Shear Machine Operation

- Press Brake Operation

- CNC Machine Operation

- Laser Cutting

Work Experience

Nipping Machine Operator

- Troubleshot and resolved machine breakdowns to minimize downtime and maximize productivity.

- Followed industry best practices and safety protocols for nipping machine operation.

- Worked effectively as part of a production team to meet production targets.

- Exhibited attention to detail and a commitment to quality assurance.

Nipping Machine Operator

- Supervised and operated high-speed nipping machines for fabric roll production.

- Established proper nipping pressure, tension, and feeding systems to ensure optimal fabric quality.

- Inspected finished fabric rolls for defects and quality conformance using automated and manual techniques.

- Maintained and calibrated nipping machines to ensure peak performance and precision.

Certificates

- Certified Nipping Machine Operator

- Certified Sheet Metal Fabricator

- Certified Weld Inspector

- Certified Quality Control Inspector

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Nipping Machine Operator

- Highlight your experience operating nipping machines and other metalworking equipment.

- Quantify your accomplishments whenever possible, using specific numbers and metrics.

- Demonstrate your knowledge of metalworking techniques and safety protocols.

- Tailor your resume to each job you apply for, highlighting the skills and experience that are most relevant to the position.

- Proofread your resume carefully before submitting it.

Essential Experience Highlights for a Strong Nipping Machine Operator Resume

- Operate nipping machines to cut, shape, and form metal sheets according to specifications.

- Set up and adjust nipping machines to ensure optimal performance and product quality.

- Inspect finished products to ensure they meet quality standards.

- Maintain a clean and organized work area.

- Follow safety protocols and procedures.

- Troubleshoot and resolve machine malfunctions.

- Assist with the maintenance and repair of nipping machines.

Frequently Asked Questions (FAQ’s) For Nipping Machine Operator

What is a nipping machine?

A nipping machine is a type of metalworking machine that is used to cut, shape, and form metal sheets. Nipping machines use a rotating blade to cut through the metal, and they can be used to create a variety of shapes and sizes.

What are the different types of nipping machines?

There are many different types of nipping machines, each with its own unique set of features and capabilities. Some of the most common types of nipping machines include:

- Manual nipping machines

- Power nipping machines

- Hydraulic nipping machines

- Pneumatic nipping machines

- CNC nipping machines

What are the safety precautions that should be taken when operating a nipping machine?

There are a number of safety precautions that should be taken when operating a nipping machine, including:

- Always wear appropriate safety gear, including safety glasses, gloves, and earplugs.

- Never operate a nipping machine if you are not properly trained.

- Keep your hands away from the cutting blade.

- Never attempt to clear a jam while the machine is running.

- Always follow the manufacturer’s instructions for operating the machine.

What are the benefits of using a nipping machine?

There are many benefits to using a nipping machine, including:

- Nipping machines are very precise, and they can be used to create complex shapes and designs.

- Nipping machines are relatively easy to operate, and they require minimal training.

- Nipping machines are relatively inexpensive to purchase and maintain.

- Nipping machines can be used to cut a variety of materials, including metal, plastic, and rubber.

What are the applications of nipping machines?

Nipping machines are used in a wide variety of applications, including:

- Automotive

- Aerospace

- Electronics

- Medical

- Construction