Are you a seasoned Non-Destructive Evaluation Technician (NDE Technician) seeking a new career path? Discover our professionally built Non-Destructive Evaluation Technician (NDE Technician) Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

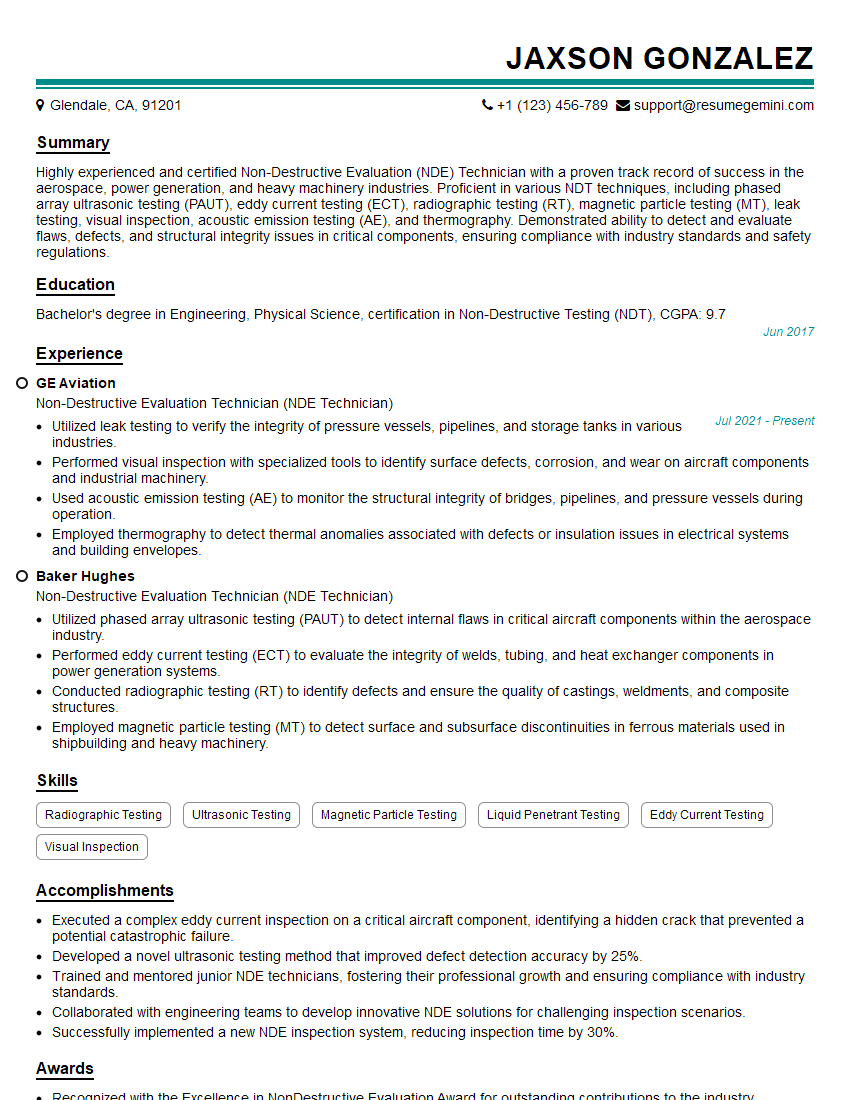

Jaxson Gonzalez

Non-Destructive Evaluation Technician (NDE Technician)

Summary

Highly experienced and certified Non-Destructive Evaluation (NDE) Technician with a proven track record of success in the aerospace, power generation, and heavy machinery industries. Proficient in various NDT techniques, including phased array ultrasonic testing (PAUT), eddy current testing (ECT), radiographic testing (RT), magnetic particle testing (MT), leak testing, visual inspection, acoustic emission testing (AE), and thermography. Demonstrated ability to detect and evaluate flaws, defects, and structural integrity issues in critical components, ensuring compliance with industry standards and safety regulations.

Education

Bachelor’s degree in Engineering, Physical Science, certification in Non-Destructive Testing (NDT)

June 2017

Skills

- Radiographic Testing

- Ultrasonic Testing

- Magnetic Particle Testing

- Liquid Penetrant Testing

- Eddy Current Testing

- Visual Inspection

Work Experience

Non-Destructive Evaluation Technician (NDE Technician)

- Utilized leak testing to verify the integrity of pressure vessels, pipelines, and storage tanks in various industries.

- Performed visual inspection with specialized tools to identify surface defects, corrosion, and wear on aircraft components and industrial machinery.

- Used acoustic emission testing (AE) to monitor the structural integrity of bridges, pipelines, and pressure vessels during operation.

- Employed thermography to detect thermal anomalies associated with defects or insulation issues in electrical systems and building envelopes.

Non-Destructive Evaluation Technician (NDE Technician)

- Utilized phased array ultrasonic testing (PAUT) to detect internal flaws in critical aircraft components within the aerospace industry.

- Performed eddy current testing (ECT) to evaluate the integrity of welds, tubing, and heat exchanger components in power generation systems.

- Conducted radiographic testing (RT) to identify defects and ensure the quality of castings, weldments, and composite structures.

- Employed magnetic particle testing (MT) to detect surface and subsurface discontinuities in ferrous materials used in shipbuilding and heavy machinery.

Accomplishments

- Executed a complex eddy current inspection on a critical aircraft component, identifying a hidden crack that prevented a potential catastrophic failure.

- Developed a novel ultrasonic testing method that improved defect detection accuracy by 25%.

- Trained and mentored junior NDE technicians, fostering their professional growth and ensuring compliance with industry standards.

- Collaborated with engineering teams to develop innovative NDE solutions for challenging inspection scenarios.

- Successfully implemented a new NDE inspection system, reducing inspection time by 30%.

Awards

- Recognized with the Excellence in NonDestructive Evaluation Award for outstanding contributions to the industry.

- Certified as a Level III NDE Technician by the American Society for NonDestructive Testing (ASNT).

- Received Employee of the Year award for exceptional performance and dedication to the NonDestructive Evaluation department.

- Recognized by the International Society for NonDestructive Testing (ISNT) for contributions to the advancement of the profession.

Certificates

- ASNT AS-NTCP

- NAS 410/411 Non-Destructive Testing Specialist

- API 510 Pressure Vessel Inspector

- AWS Certified Weld Inspector

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Non-Destructive Evaluation Technician (NDE Technician)

- Quantify your accomplishments whenever possible using specific numbers and metrics.

- Highlight your key skills and experience using industry-specific keywords.

- Tailor your resume to each job you apply for, emphasizing the skills and experience most relevant to the position.

- Proofread your resume carefully for any errors in grammar, spelling, or formatting.

Essential Experience Highlights for a Strong Non-Destructive Evaluation Technician (NDE Technician) Resume

- Conduct non-destructive testing using advanced techniques such as phased array ultrasonic testing (PAUT), eddy current testing (ECT), and radiographic testing (RT) on critical components and structures.

- Analyze test results to identify defects and flaws, and recommend appropriate corrective actions.

- Interpret and document inspection findings in accordance with industry standards and client specifications.

- Maintain and calibrate NDT equipment, ensuring accuracy and reliability of test results.

- Collaborate with engineers and quality control personnel to develop and implement testing procedures.

- Adhere to safety protocols and maintain a safe work environment during inspections.

- Stay abreast of advancements in NDT technologies and best practices.

Frequently Asked Questions (FAQ’s) For Non-Destructive Evaluation Technician (NDE Technician)

What is the role of a Non-Destructive Evaluation Technician?

Non-Destructive Evaluation (NDE) Technicians play a crucial role in ensuring the safety and integrity of critical components and structures in various industries. They use specialized techniques to detect and evaluate flaws, defects, and structural issues without damaging or altering the inspected item.

What are the common NDT techniques used by technicians?

Common NDT techniques include: Phased array ultrasonic testing (PAUT), eddy current testing (ECT), radiographic testing (RT), magnetic particle testing (MT), leak testing, visual inspection, acoustic emission testing (AE), and thermography.

What industries employ Non-Destructive Evaluation Technicians?

NDE Technicians are employed in a wide range of industries, including aerospace, automotive, power generation, oil and gas, manufacturing, shipbuilding, and construction.

What are the educational requirements for becoming an NDE Technician?

Typically, Non-Destructive Evaluation Technicians hold a Bachelor’s degree in Engineering, Physical Science, or a related field. Industry certifications are also required, such as those offered by the American Society for Nondestructive Testing (ASNT).

What are the career prospects for Non-Destructive Evaluation Technicians?

The demand for Non-Destructive Evaluation Technicians is expected to grow as industries prioritize the safety and reliability of their critical assets. With experience and specialized certifications, NDE Technicians can advance to supervisory or management roles.