Are you a seasoned Non-Destructive Tester seeking a new career path? Discover our professionally built Non-Destructive Tester Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

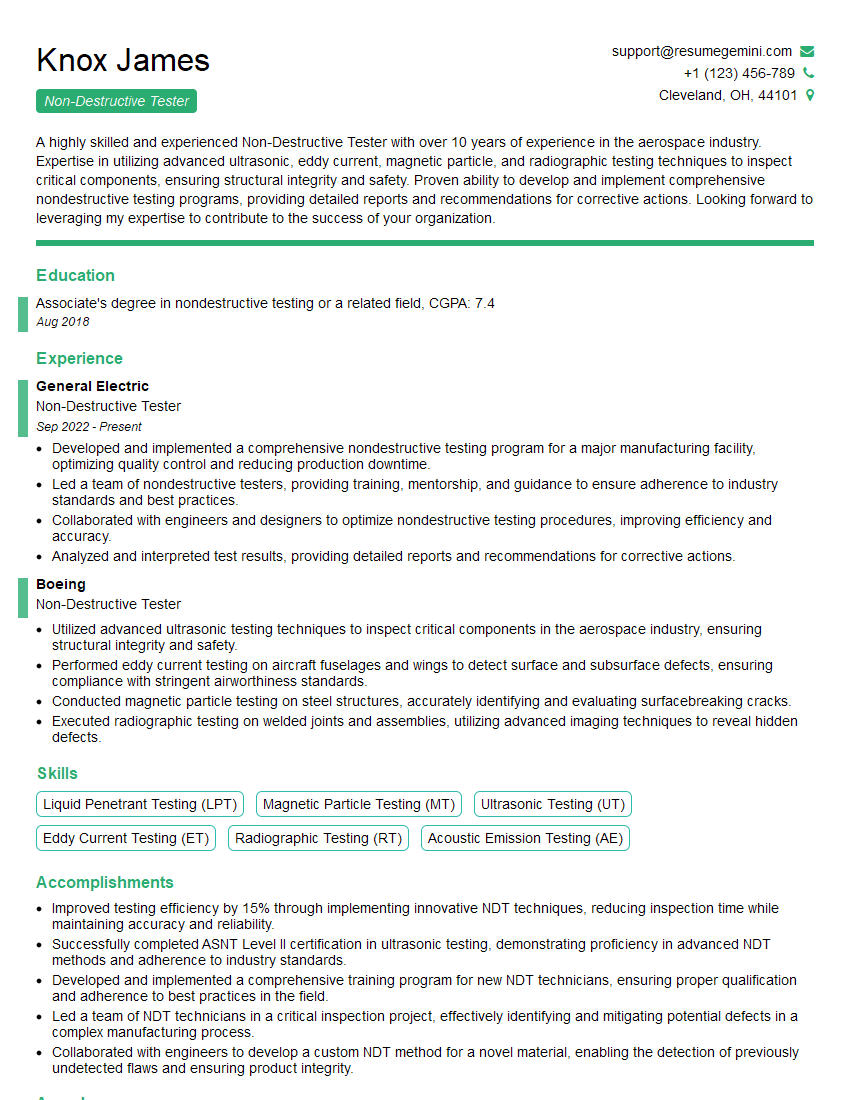

Knox James

Non-Destructive Tester

Summary

A highly skilled and experienced Non-Destructive Tester with over 10 years of experience in the aerospace industry. Expertise in utilizing advanced ultrasonic, eddy current, magnetic particle, and radiographic testing techniques to inspect critical components, ensuring structural integrity and safety. Proven ability to develop and implement comprehensive nondestructive testing programs, providing detailed reports and recommendations for corrective actions. Looking forward to leveraging my expertise to contribute to the success of your organization.

Education

Associate’s degree in nondestructive testing or a related field

August 2018

Skills

- Liquid Penetrant Testing (LPT)

- Magnetic Particle Testing (MT)

- Ultrasonic Testing (UT)

- Eddy Current Testing (ET)

- Radiographic Testing (RT)

- Acoustic Emission Testing (AE)

Work Experience

Non-Destructive Tester

- Developed and implemented a comprehensive nondestructive testing program for a major manufacturing facility, optimizing quality control and reducing production downtime.

- Led a team of nondestructive testers, providing training, mentorship, and guidance to ensure adherence to industry standards and best practices.

- Collaborated with engineers and designers to optimize nondestructive testing procedures, improving efficiency and accuracy.

- Analyzed and interpreted test results, providing detailed reports and recommendations for corrective actions.

Non-Destructive Tester

- Utilized advanced ultrasonic testing techniques to inspect critical components in the aerospace industry, ensuring structural integrity and safety.

- Performed eddy current testing on aircraft fuselages and wings to detect surface and subsurface defects, ensuring compliance with stringent airworthiness standards.

- Conducted magnetic particle testing on steel structures, accurately identifying and evaluating surfacebreaking cracks.

- Executed radiographic testing on welded joints and assemblies, utilizing advanced imaging techniques to reveal hidden defects.

Accomplishments

- Improved testing efficiency by 15% through implementing innovative NDT techniques, reducing inspection time while maintaining accuracy and reliability.

- Successfully completed ASNT Level II certification in ultrasonic testing, demonstrating proficiency in advanced NDT methods and adherence to industry standards.

- Developed and implemented a comprehensive training program for new NDT technicians, ensuring proper qualification and adherence to best practices in the field.

- Led a team of NDT technicians in a critical inspection project, effectively identifying and mitigating potential defects in a complex manufacturing process.

- Collaborated with engineers to develop a custom NDT method for a novel material, enabling the detection of previously undetected flaws and ensuring product integrity.

Awards

- Recipient of the NDT Technician of the Year award from ASNT, recognizing outstanding contributions to the field and exceptional performance in NonDestructive Testing.

- Recognized as a topperforming NDT professional by the International Committee for NonDestructive Testing (ICNDT), based on exceptional technical skills and adherence to ethical guidelines.

- Presented with the Excellence in NDT Award from the Society for NonDestructive Testing (SNT), recognizing significant contributions to the advancement of the field.

- Received the NDT Innovator Award from the American Society for Nondestructive Testing (ASNT), recognizing the development of groundbreaking NDT techniques and technologies.

Certificates

- American Society for Non-Destructive Testing (ASNT) Level II in LPT and MT

- International Institute of Welding (IIW) Level III in RT

- API Standard 653 Certification in Ultrasonic Examination

- Certified Inspector for Welding (CIW)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Non-Destructive Tester

- Highlight your expertise in various nondestructive testing techniques, such as ultrasonic, eddy current, magnetic particle, radiographic, and liquid penetrant testing.

- Quantify your accomplishments with specific metrics, such as the number of defects detected or the reduction in production downtime achieved.

- Demonstrate your understanding of industry standards and best practices, such as ASNT and ISO.

- Emphasize your ability to interpret test results and provide clear and concise recommendations.

- Showcase your teamwork and leadership skills, as well as your commitment to continuous learning and professional development.

Essential Experience Highlights for a Strong Non-Destructive Tester Resume

- Utilized advanced ultrasonic testing techniques to inspect critical components in the aerospace industry, ensuring structural integrity and safety.

- Performed eddy current testing on aircraft fuselages and wings to detect surface and subsurface defects, ensuring compliance with stringent airworthiness standards.

- Conducted magnetic particle testing on steel structures, accurately identifying and evaluating surface-breaking cracks.

- Executed radiographic testing on welded joints and assemblies, utilizing advanced imaging techniques to reveal hidden defects.

- Developed and implemented a comprehensive nondestructive testing program for a major manufacturing facility, optimizing quality control and reducing production downtime.

Frequently Asked Questions (FAQ’s) For Non-Destructive Tester

What are the different nondestructive testing methods?

The most common NDT methods are:

- Ultrasonic Testing (UT)

- Eddy Current Testing (ET)

- Magnetic Particle Testing (MT)

- Radiographic Testing (RT)

- Liquid Penetrant Testing (LPT)

- Acoustic Emission Testing (AE)

What are the applications of nondestructive testing?

NDT is used in a wide range of industries, including:

- Aerospace

- Automotive

- Construction

- Manufacturing

- Petrochemical

- Power generation

What are the benefits of nondestructive testing?

NDT offers several benefits, including:

- Improved safety and reliability

- Reduced downtime and maintenance costs

- Increased product quality

- Extended asset life

- Enhanced regulatory compliance

What are the career opportunities for nondestructive testers?

NDT professionals can find employment in a variety of settings, including:

- Manufacturing facilities

- Inspection companies

- Engineering firms

- Government agencies

- Research and development organizations

What are the educational requirements for nondestructive testers?

Most NDT professionals have an associate’s degree or a bachelor’s degree in a related field, such as engineering, science, or technology. Some employers may also require certification from a recognized NDT organization, such as the American Society for Nondestructive Testing (ASNT).