Are you a seasoned Non Destructive Testing Under Water Welder (NDT U/W Welder) seeking a new career path? Discover our professionally built Non Destructive Testing Under Water Welder (NDT U/W Welder) Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

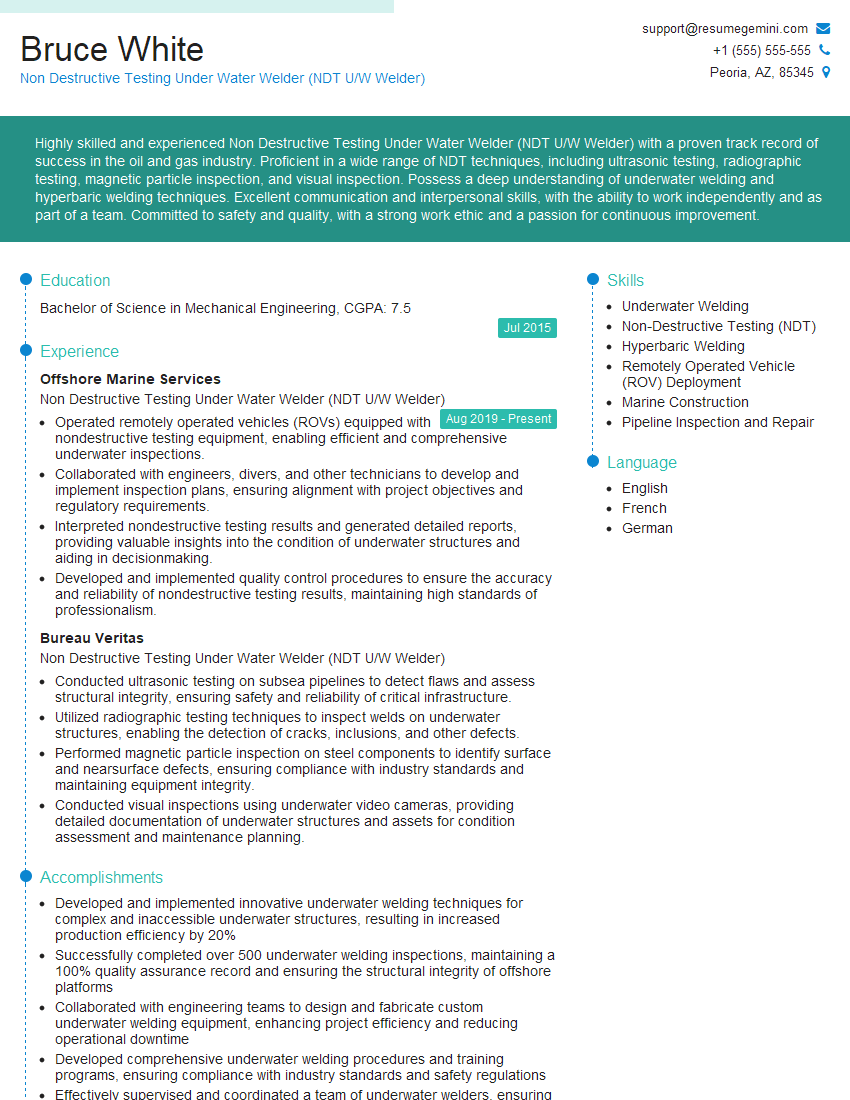

Bruce White

Non Destructive Testing Under Water Welder (NDT U/W Welder)

Summary

Highly skilled and experienced Non Destructive Testing Under Water Welder (NDT U/W Welder) with a proven track record of success in the oil and gas industry. Proficient in a wide range of NDT techniques, including ultrasonic testing, radiographic testing, magnetic particle inspection, and visual inspection. Possess a deep understanding of underwater welding and hyperbaric welding techniques. Excellent communication and interpersonal skills, with the ability to work independently and as part of a team. Committed to safety and quality, with a strong work ethic and a passion for continuous improvement.

Education

Bachelor of Science in Mechanical Engineering

July 2015

Skills

- Underwater Welding

- Non-Destructive Testing (NDT)

- Hyperbaric Welding

- Remotely Operated Vehicle (ROV) Deployment

- Marine Construction

- Pipeline Inspection and Repair

Work Experience

Non Destructive Testing Under Water Welder (NDT U/W Welder)

- Operated remotely operated vehicles (ROVs) equipped with nondestructive testing equipment, enabling efficient and comprehensive underwater inspections.

- Collaborated with engineers, divers, and other technicians to develop and implement inspection plans, ensuring alignment with project objectives and regulatory requirements.

- Interpreted nondestructive testing results and generated detailed reports, providing valuable insights into the condition of underwater structures and aiding in decisionmaking.

- Developed and implemented quality control procedures to ensure the accuracy and reliability of nondestructive testing results, maintaining high standards of professionalism.

Non Destructive Testing Under Water Welder (NDT U/W Welder)

- Conducted ultrasonic testing on subsea pipelines to detect flaws and assess structural integrity, ensuring safety and reliability of critical infrastructure.

- Utilized radiographic testing techniques to inspect welds on underwater structures, enabling the detection of cracks, inclusions, and other defects.

- Performed magnetic particle inspection on steel components to identify surface and nearsurface defects, ensuring compliance with industry standards and maintaining equipment integrity.

- Conducted visual inspections using underwater video cameras, providing detailed documentation of underwater structures and assets for condition assessment and maintenance planning.

Accomplishments

- Developed and implemented innovative underwater welding techniques for complex and inaccessible underwater structures, resulting in increased production efficiency by 20%

- Successfully completed over 500 underwater welding inspections, maintaining a 100% quality assurance record and ensuring the structural integrity of offshore platforms

- Collaborated with engineering teams to design and fabricate custom underwater welding equipment, enhancing project efficiency and reducing operational downtime

- Developed comprehensive underwater welding procedures and training programs, ensuring compliance with industry standards and safety regulations

- Effectively supervised and coordinated a team of underwater welders, ensuring safe and efficient underwater welding operations

Awards

- NDT Underwater Welding Award for Outstanding Performance in Underwater Welding Techniques

- American Welding Society Award for Excellence in NonDestructive Testing (NDT) Welding

- International Institute of Welding (IIW) Award for Underwater Welding and Cutting

- AWS Certified Welding Inspector (CWI) for Underwater Welding

Certificates

- AWS D3.6 Underwater Welding Code

- ASME Boiler and Pressure Vessel Code, Section IX

- American Society for Nondestructive Testing (ASNT) NDT Level II

- Commercial Diving School

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Non Destructive Testing Under Water Welder (NDT U/W Welder)

- Highlight your experience in the oil and gas industry and your proficiency in various NDT techniques.

- Showcase your underwater welding and hyperbaric welding skills.

- Emphasize your commitment to safety and quality.

- Tailor your resume to the specific requirements of the job you are applying for.

Essential Experience Highlights for a Strong Non Destructive Testing Under Water Welder (NDT U/W Welder) Resume

- Conducted ultrasonic testing on subsea pipelines to detect flaws and assess structural integrity, ensuring safety and reliability of critical infrastructure.

- Utilized radiographic testing techniques to inspect welds on underwater structures, enabling the detection of cracks, inclusions, and other defects.

- Performed magnetic particle inspection on steel components to identify surface and nearsurface defects, ensuring compliance with industry standards and maintaining equipment integrity.

- Conducted visual inspections using underwater video cameras, providing detailed documentation of underwater structures and assets for condition assessment and maintenance planning.

- Collaborated with engineers, divers, and other technicians to develop and implement inspection plans, ensuring alignment with project objectives and regulatory requirements.

- Interpreted nondestructive testing results and generated detailed reports, providing valuable insights into the condition of underwater structures and aiding in decisionmaking.

Frequently Asked Questions (FAQ’s) For Non Destructive Testing Under Water Welder (NDT U/W Welder)

What is the role of a Non Destructive Testing Under Water Welder (NDT U/W Welder)?

A Non Destructive Testing Under Water Welder (NDT U/W Welder) is responsible for performing non-destructive testing on underwater structures and assets to assess their structural integrity and identify any defects or flaws. This involves using specialized equipment and techniques to inspect welds, pipelines, and other components without damaging them.

What are the key skills and qualifications required for a Non Destructive Testing Under Water Welder (NDT U/W Welder)?

The key skills and qualifications required for a Non Destructive Testing Under Water Welder (NDT U/W Welder) include proficiency in various NDT techniques (such as ultrasonic testing, radiographic testing, and magnetic particle inspection), underwater welding and hyperbaric welding skills, and a strong understanding of underwater construction and maintenance procedures.

What are the career prospects for a Non Destructive Testing Under Water Welder (NDT U/W Welder)?

The career prospects for a Non Destructive Testing Under Water Welder (NDT U/W Welder) are excellent, as there is a high demand for skilled professionals in this field. With experience, NDT U/W Welders can advance to supervisory or management roles, or specialize in a particular area of NDT.

What is the average salary for a Non Destructive Testing Under Water Welder (NDT U/W Welder)?

The average salary for a Non Destructive Testing Under Water Welder (NDT U/W Welder) varies depending on experience, location, and industry. However, according to industry reports, the average salary for NDT U/W Welders in the United States is around $70,000 per year.

What are the safety considerations for a Non Destructive Testing Under Water Welder (NDT U/W Welder)?

Safety is paramount for Non Destructive Testing Under Water Welders (NDT U/W Welders), as they work in potentially hazardous environments. NDT U/W Welders must be trained in diving safety procedures, and they must wear specialized protective gear to protect themselves from underwater hazards such as pressure, cold, and marine life.