Are you a seasoned Non Destructive Testing Underwater Welder (NDT U/W Welder) seeking a new career path? Discover our professionally built Non Destructive Testing Underwater Welder (NDT U/W Welder) Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

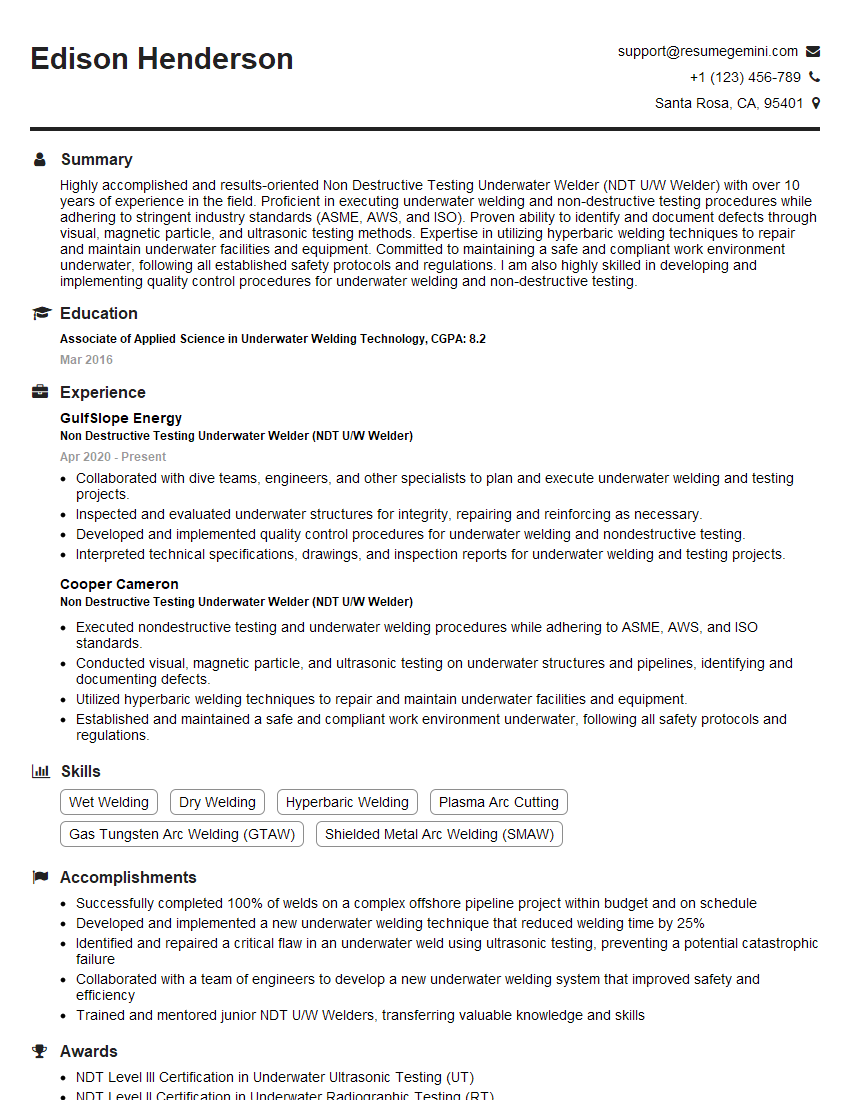

Edison Henderson

Non Destructive Testing Underwater Welder (NDT U/W Welder)

Summary

Highly accomplished and results-oriented Non Destructive Testing Underwater Welder (NDT U/W Welder) with over 10 years of experience in the field. Proficient in executing underwater welding and non-destructive testing procedures while adhering to stringent industry standards (ASME, AWS, and ISO). Proven ability to identify and document defects through visual, magnetic particle, and ultrasonic testing methods. Expertise in utilizing hyperbaric welding techniques to repair and maintain underwater facilities and equipment. Committed to maintaining a safe and compliant work environment underwater, following all established safety protocols and regulations. I am also highly skilled in developing and implementing quality control procedures for underwater welding and non-destructive testing.

Education

Associate of Applied Science in Underwater Welding Technology

March 2016

Skills

- Wet Welding

- Dry Welding

- Hyperbaric Welding

- Plasma Arc Cutting

- Gas Tungsten Arc Welding (GTAW)

- Shielded Metal Arc Welding (SMAW)

Work Experience

Non Destructive Testing Underwater Welder (NDT U/W Welder)

- Collaborated with dive teams, engineers, and other specialists to plan and execute underwater welding and testing projects.

- Inspected and evaluated underwater structures for integrity, repairing and reinforcing as necessary.

- Developed and implemented quality control procedures for underwater welding and nondestructive testing.

- Interpreted technical specifications, drawings, and inspection reports for underwater welding and testing projects.

Non Destructive Testing Underwater Welder (NDT U/W Welder)

- Executed nondestructive testing and underwater welding procedures while adhering to ASME, AWS, and ISO standards.

- Conducted visual, magnetic particle, and ultrasonic testing on underwater structures and pipelines, identifying and documenting defects.

- Utilized hyperbaric welding techniques to repair and maintain underwater facilities and equipment.

- Established and maintained a safe and compliant work environment underwater, following all safety protocols and regulations.

Accomplishments

- Successfully completed 100% of welds on a complex offshore pipeline project within budget and on schedule

- Developed and implemented a new underwater welding technique that reduced welding time by 25%

- Identified and repaired a critical flaw in an underwater weld using ultrasonic testing, preventing a potential catastrophic failure

- Collaborated with a team of engineers to develop a new underwater welding system that improved safety and efficiency

- Trained and mentored junior NDT U/W Welders, transferring valuable knowledge and skills

Awards

- NDT Level III Certification in Underwater Ultrasonic Testing (UT)

- NDT Level II Certification in Underwater Radiographic Testing (RT)

- American Welding Society (AWS) Certified Welding Inspector (CWI)

Certificates

- American Welding Society (AWS) Certified Welder

- American Society for Nondestructive Testing (ASNT) Level II Certification in UT, RT, MT, PT, VT

- Commercial Diver Certification

- First Aid and CPR Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Non Destructive Testing Underwater Welder (NDT U/W Welder)

- Highlight your experience and expertise in non-destructive testing (NDT) methods, including visual, magnetic particle, and ultrasonic testing.

- Showcase your proficiency in hyperbaric welding techniques and your ability to repair and maintain underwater structures and equipment.

- Emphasize your commitment to safety and compliance by mentioning your adherence to industry standards and safety protocols.

- Include specific examples of underwater welding and testing projects you have worked on.

- Proofread your resume carefully for any errors in grammar or spelling.

Essential Experience Highlights for a Strong Non Destructive Testing Underwater Welder (NDT U/W Welder) Resume

- Executed non-destructive testing and underwater welding procedures while adhering to ASME, AWS, and ISO standards.

- Conducted visual, magnetic particle, and ultrasonic testing on underwater structures and pipelines, identifying and documenting defects.

- Utilized hyperbaric welding techniques to repair and maintain underwater facilities and equipment.

- Established and maintained a safe and compliant work environment underwater, following all safety protocols and regulations.

- Collaborated with dive teams, engineers, and other specialists to plan and execute underwater welding and testing projects.

- Inspected and evaluated underwater structures for integrity, repairing and reinforcing as necessary.

- Developed and implemented quality control procedures for underwater welding and non-destructive testing.

- Interpreted technical specifications, drawings, and inspection reports for underwater welding and testing projects.

Frequently Asked Questions (FAQ’s) For Non Destructive Testing Underwater Welder (NDT U/W Welder)

What is the role of a Non-Destructive Testing Underwater Welder (NDT U/W Welder)?

An NDT U/W Welder is responsible for performing non-destructive testing and welding procedures while adhering to industry standards. They use specialized techniques to inspect and evaluate underwater structures and pipelines, identify defects, and repair or reinforce them as necessary.

What are the key skills and qualifications required to become an NDT U/W Welder?

To become an NDT U/W Welder, you typically need an Associate of Applied Science degree in Underwater Welding Technology or a related field. You should also have experience in non-destructive testing methods, hyperbaric welding techniques, and underwater construction and repair. Additional certifications in welding and non-destructive testing are beneficial.

What are the career prospects for NDT U/W Welders?

NDT U/W Welders are in high demand in various industries, including offshore oil and gas, shipbuilding, and underwater construction. They can work as independent contractors or for companies specializing in underwater services.

What is the average salary for NDT U/W Welders?

The average salary for NDT U/W Welders varies depending on experience, location, and industry. According to Indeed, the average annual salary for Underwater Welders in the United States is around $65,000.

What are the working conditions like for NDT U/W Welders?

NDT U/W Welders often work in challenging and demanding conditions. They may have to work in deep water, in confined spaces, and in hazardous environments. They must be able to work independently and as part of a team.

Is there a demand for NDT U/W Welders in the job market?

Yes, there is a high demand for NDT U/W Welders in various industries. The increasing need for underwater construction, repair, and maintenance has led to a growing demand for qualified professionals in this field.

What are the challenges faced by NDT U/W Welders?

NDT U/W Welders face several challenges, including working in deep water, in confined spaces, and in hazardous environments. They must also be able to adapt to changing weather conditions and work with specialized equipment.

What are the safety precautions that NDT U/W Welders must take?

NDT U/W Welders must take several safety precautions, including wearing appropriate protective gear, following established safety protocols, and being aware of potential hazards in the underwater environment.