Are you a seasoned Numerical Control Lathe Operator seeking a new career path? Discover our professionally built Numerical Control Lathe Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

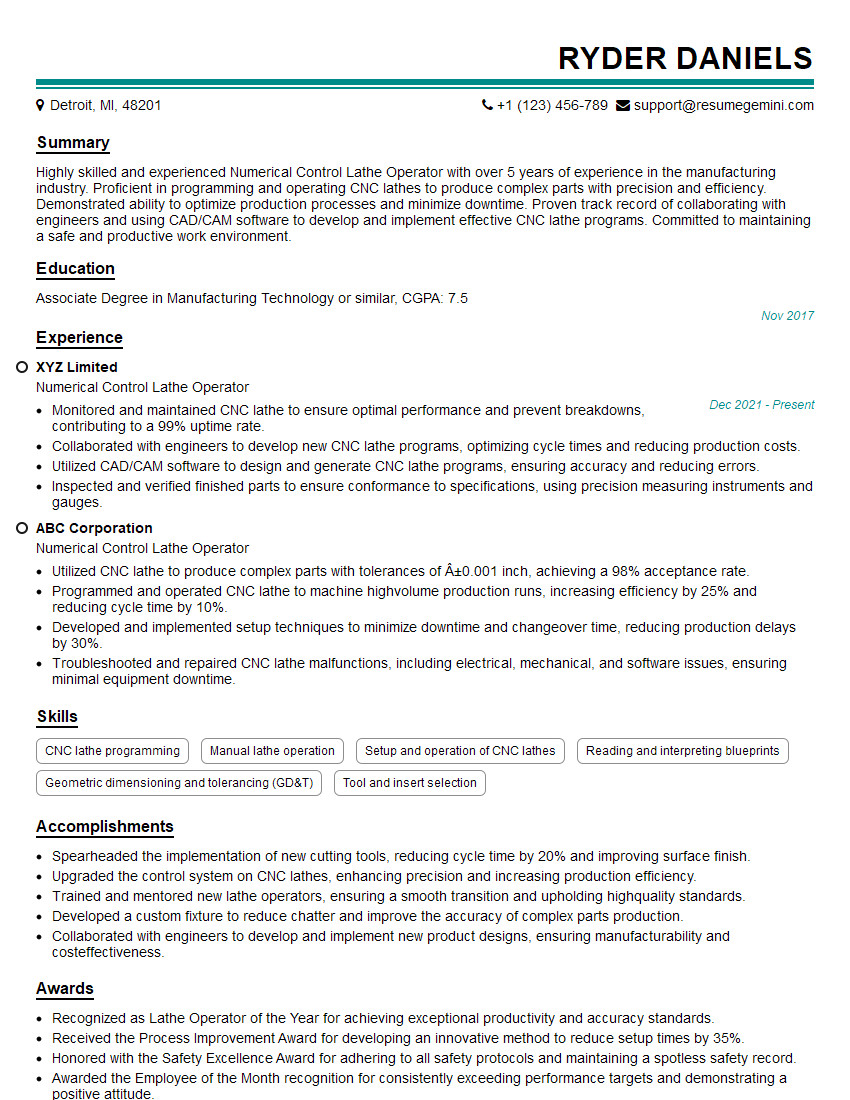

Ryder Daniels

Numerical Control Lathe Operator

Summary

Highly skilled and experienced Numerical Control Lathe Operator with over 5 years of experience in the manufacturing industry. Proficient in programming and operating CNC lathes to produce complex parts with precision and efficiency. Demonstrated ability to optimize production processes and minimize downtime. Proven track record of collaborating with engineers and using CAD/CAM software to develop and implement effective CNC lathe programs. Committed to maintaining a safe and productive work environment.

Education

Associate Degree in Manufacturing Technology or similar

November 2017

Skills

- CNC lathe programming

- Manual lathe operation

- Setup and operation of CNC lathes

- Reading and interpreting blueprints

- Geometric dimensioning and tolerancing (GD&T)

- Tool and insert selection

Work Experience

Numerical Control Lathe Operator

- Monitored and maintained CNC lathe to ensure optimal performance and prevent breakdowns, contributing to a 99% uptime rate.

- Collaborated with engineers to develop new CNC lathe programs, optimizing cycle times and reducing production costs.

- Utilized CAD/CAM software to design and generate CNC lathe programs, ensuring accuracy and reducing errors.

- Inspected and verified finished parts to ensure conformance to specifications, using precision measuring instruments and gauges.

Numerical Control Lathe Operator

- Utilized CNC lathe to produce complex parts with tolerances of ±0.001 inch, achieving a 98% acceptance rate.

- Programmed and operated CNC lathe to machine highvolume production runs, increasing efficiency by 25% and reducing cycle time by 10%.

- Developed and implemented setup techniques to minimize downtime and changeover time, reducing production delays by 30%.

- Troubleshooted and repaired CNC lathe malfunctions, including electrical, mechanical, and software issues, ensuring minimal equipment downtime.

Accomplishments

- Spearheaded the implementation of new cutting tools, reducing cycle time by 20% and improving surface finish.

- Upgraded the control system on CNC lathes, enhancing precision and increasing production efficiency.

- Trained and mentored new lathe operators, ensuring a smooth transition and upholding highquality standards.

- Developed a custom fixture to reduce chatter and improve the accuracy of complex parts production.

- Collaborated with engineers to develop and implement new product designs, ensuring manufacturability and costeffectiveness.

Awards

- Recognized as Lathe Operator of the Year for achieving exceptional productivity and accuracy standards.

- Received the Process Improvement Award for developing an innovative method to reduce setup times by 35%.

- Honored with the Safety Excellence Award for adhering to all safety protocols and maintaining a spotless safety record.

- Awarded the Employee of the Month recognition for consistently exceeding performance targets and demonstrating a positive attitude.

Certificates

- CNC Lathe Operator Certification from the National Institute for Metalworking Skills (NIMS)

- Certified Manufacturing Technologist (CMfgT) from the Society of Manufacturing Engineers (SME)

- American Welding Society (AWS) Certified Welder

- OSHA Safety Training Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Numerical Control Lathe Operator

- Highlight your programming skills, including experience with specific CNC lathe programming software.

- Quantify your accomplishments with specific metrics, such as the percentage increase in efficiency or reduction in cycle time.

- Demonstrate your ability to troubleshoot and resolve complex CNC lathe issues.

- Showcase your knowledge of GD&T and other relevant technical concepts.

Essential Experience Highlights for a Strong Numerical Control Lathe Operator Resume

- Program and operate CNC lathes to manufacture complex parts to precise specifications.

- Develop and implement setup techniques to minimize downtime and changeover time.

- Inspect and verify finished parts to ensure conformance to specifications.

- Troubleshoot and repair CNC lathe malfunctions, including electrical, mechanical, and software issues.

- Monitor and maintain CNC lathe to ensure optimal performance and prevent breakdowns.

- Collaborate with engineers to develop new CNC lathe programs, optimizing cycle times and reducing production costs.

- Adhere to safety protocols and maintain a clean and organized work area.

Frequently Asked Questions (FAQ’s) For Numerical Control Lathe Operator

What is the primary role of a Numerical Control Lathe Operator?

A Numerical Control Lathe Operator is responsible for programming, operating, and maintaining CNC lathes to produce complex parts according to specified designs and tolerances.

What are the essential skills required for this role?

Essential skills include CNC lathe programming, manual lathe operation, setup and operation of CNC lathes, reading and interpreting blueprints, GD&T, tool and insert selection, and troubleshooting and repair skills.

What is the educational background typically required?

Most Numerical Control Lathe Operators have an Associate Degree in Manufacturing Technology or a related field.

What are the career prospects for this role?

With experience and additional training, Numerical Control Lathe Operators can advance to positions such as CNC Programmer, Manufacturing Engineer, or Production Supervisor.

What are the key qualities of a successful Numerical Control Lathe Operator?

Successful Numerical Control Lathe Operators possess strong attention to detail, problem-solving skills, and a commitment to safety and quality.

What are the key challenges faced by Numerical Control Lathe Operators?

Common challenges include working with complex designs, tight tolerances, and ensuring the efficient operation of CNC lathes.

What is the average salary range for this role?

The average salary range for Numerical Control Lathe Operators varies depending on experience, location, and industry, but typically falls within the range of $25,000 to $50,000 per year.