Are you a seasoned Nut Tightener seeking a new career path? Discover our professionally built Nut Tightener Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

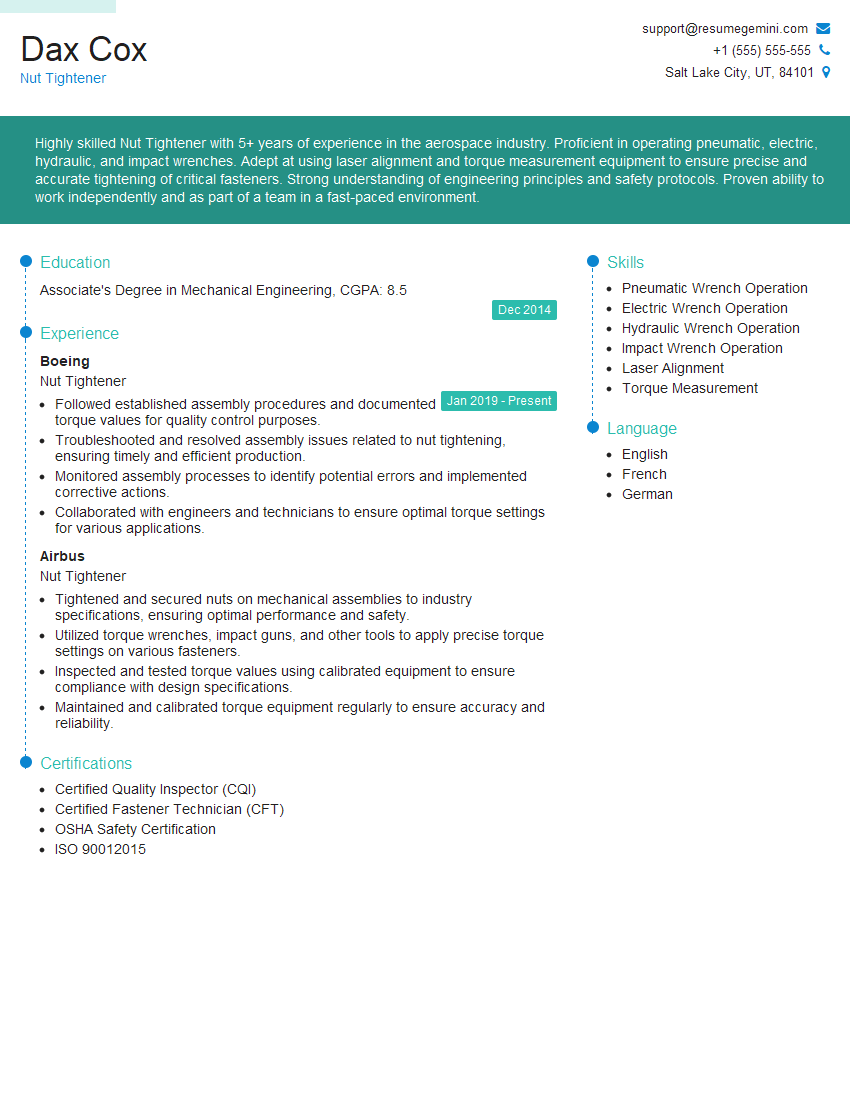

Dax Cox

Nut Tightener

Summary

Highly skilled Nut Tightener with 5+ years of experience in the aerospace industry. Proficient in operating pneumatic, electric, hydraulic, and impact wrenches. Adept at using laser alignment and torque measurement equipment to ensure precise and accurate tightening of critical fasteners. Strong understanding of engineering principles and safety protocols. Proven ability to work independently and as part of a team in a fast-paced environment.

Education

Associate’s Degree in Mechanical Engineering

December 2014

Skills

- Pneumatic Wrench Operation

- Electric Wrench Operation

- Hydraulic Wrench Operation

- Impact Wrench Operation

- Laser Alignment

- Torque Measurement

Work Experience

Nut Tightener

- Followed established assembly procedures and documented torque values for quality control purposes.

- Troubleshooted and resolved assembly issues related to nut tightening, ensuring timely and efficient production.

- Monitored assembly processes to identify potential errors and implemented corrective actions.

- Collaborated with engineers and technicians to ensure optimal torque settings for various applications.

Nut Tightener

- Tightened and secured nuts on mechanical assemblies to industry specifications, ensuring optimal performance and safety.

- Utilized torque wrenches, impact guns, and other tools to apply precise torque settings on various fasteners.

- Inspected and tested torque values using calibrated equipment to ensure compliance with design specifications.

- Maintained and calibrated torque equipment regularly to ensure accuracy and reliability.

Certificates

- Certified Quality Inspector (CQI)

- Certified Fastener Technician (CFT)

- OSHA Safety Certification

- ISO 90012015

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Nut Tightener

- Highlight your experience and skills in operating various types of wrenches and torque measurement equipment.

- Quantify your accomplishments and provide specific examples of your contributions to the team.

- Demonstrate your understanding of engineering principles and safety protocols.

- Emphasize your ability to work independently and as part of a team in a fast-paced environment.

- Proofread your resume carefully for any errors in grammar or spelling.

Essential Experience Highlights for a Strong Nut Tightener Resume

- Tighten, loosen, and remove nuts and bolts using pneumatic, electric, hydraulic, and impact wrenches

- Use laser alignment and torque measurement equipment to ensure precise and accurate tightening

- Inspect and identify damaged or loose nuts and bolts, and recommend appropriate repairs

- Maintain a clean and organized work area, and follow all safety protocols

- Operate machinery and equipment in a safe and efficient manner

- Adhere to established quality standards and specifications

- Work independently and as part of a team to meet production goals

Frequently Asked Questions (FAQ’s) For Nut Tightener

What is the role of a Nut Tightener?

A Nut Tightener is responsible for tightening, loosening, and removing nuts and bolts using various types of wrenches. They also use laser alignment and torque measurement equipment to ensure precise and accurate tightening.

What are the qualifications for becoming a Nut Tightener?

Typically, a Nut Tightener requires an Associate’s Degree in Mechanical Engineering or a related field, with experience in operating various types of wrenches and torque measurement equipment.

What are the key skills for a Nut Tightener?

Key skills for a Nut Tightener include proficiency in operating pneumatic, electric, hydraulic, and impact wrenches, as well as the ability to use laser alignment and torque measurement equipment. They should also have a strong understanding of engineering principles and safety protocols.

What is the work environment of a Nut Tightener like?

Nut Tighteners typically work in a fast-paced environment, often in manufacturing or industrial settings. They may work independently or as part of a team, and may be required to work in confined spaces or at heights.

What is the career outlook for Nut Tighteners?

The career outlook for Nut Tighteners is expected to be stable in the coming years, with growth in the aerospace, automotive, and manufacturing industries.

What is the average salary for a Nut Tightener?

The average salary for a Nut Tightener varies depending on experience, location, and industry, but typically ranges from $20,000 to $40,000 per year.