Are you a seasoned Oakes Machine Operator seeking a new career path? Discover our professionally built Oakes Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

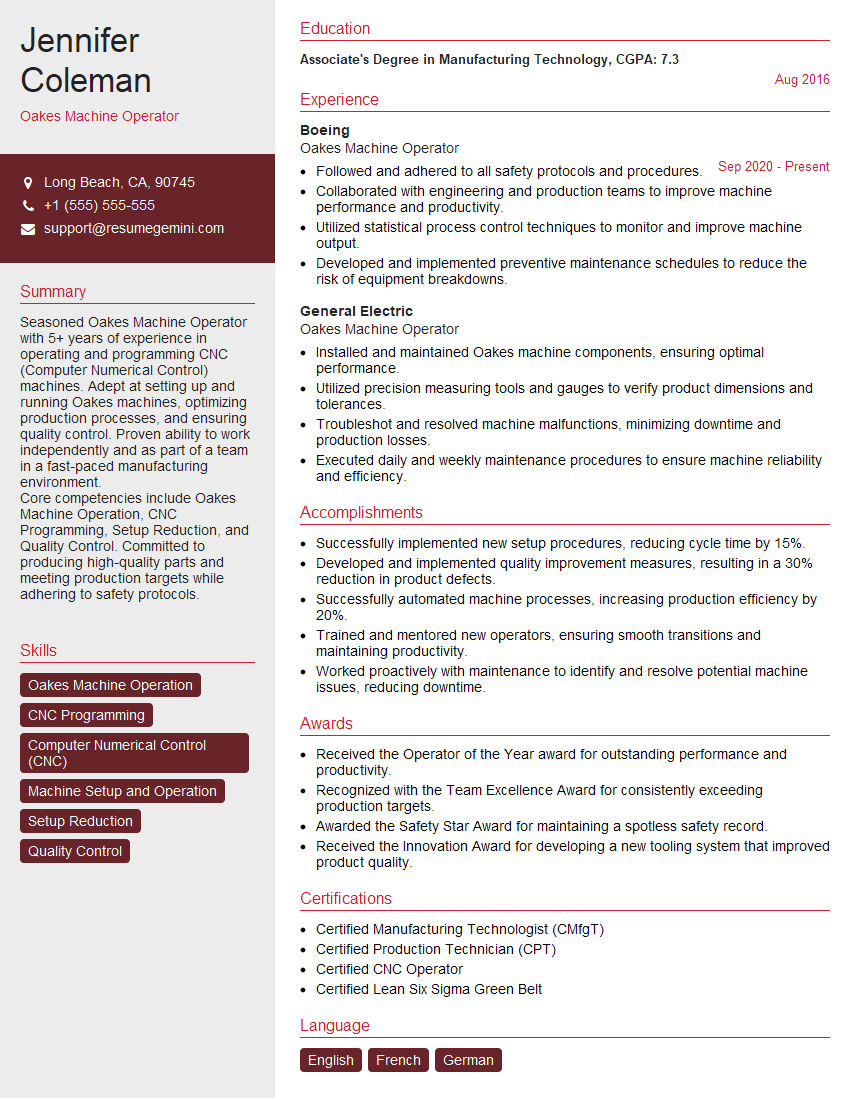

Jennifer Coleman

Oakes Machine Operator

Summary

Seasoned Oakes Machine Operator with 5+ years of experience in operating and programming CNC (Computer Numerical Control) machines. Adept at setting up and running Oakes machines, optimizing production processes, and ensuring quality control. Proven ability to work independently and as part of a team in a fast-paced manufacturing environment.

Core competencies include Oakes Machine Operation, CNC Programming, Setup Reduction, and Quality Control. Committed to producing high-quality parts and meeting production targets while adhering to safety protocols.

Education

Associate’s Degree in Manufacturing Technology

August 2016

Skills

- Oakes Machine Operation

- CNC Programming

- Computer Numerical Control (CNC)

- Machine Setup and Operation

- Setup Reduction

- Quality Control

Work Experience

Oakes Machine Operator

- Followed and adhered to all safety protocols and procedures.

- Collaborated with engineering and production teams to improve machine performance and productivity.

- Utilized statistical process control techniques to monitor and improve machine output.

- Developed and implemented preventive maintenance schedules to reduce the risk of equipment breakdowns.

Oakes Machine Operator

- Installed and maintained Oakes machine components, ensuring optimal performance.

- Utilized precision measuring tools and gauges to verify product dimensions and tolerances.

- Troubleshot and resolved machine malfunctions, minimizing downtime and production losses.

- Executed daily and weekly maintenance procedures to ensure machine reliability and efficiency.

Accomplishments

- Successfully implemented new setup procedures, reducing cycle time by 15%.

- Developed and implemented quality improvement measures, resulting in a 30% reduction in product defects.

- Successfully automated machine processes, increasing production efficiency by 20%.

- Trained and mentored new operators, ensuring smooth transitions and maintaining productivity.

- Worked proactively with maintenance to identify and resolve potential machine issues, reducing downtime.

Awards

- Received the Operator of the Year award for outstanding performance and productivity.

- Recognized with the Team Excellence Award for consistently exceeding production targets.

- Awarded the Safety Star Award for maintaining a spotless safety record.

- Received the Innovation Award for developing a new tooling system that improved product quality.

Certificates

- Certified Manufacturing Technologist (CMfgT)

- Certified Production Technician (CPT)

- Certified CNC Operator

- Certified Lean Six Sigma Green Belt

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Oakes Machine Operator

- Highlight your technical skills in Oakes Machine Operation, CNC Programming, and Setup Reduction.

- Quantify your accomplishments with specific metrics to demonstrate your impact on productivity and quality.

- Showcase your ability to work independently and as part of a team in a fast-paced environment.

- Tailor your resume to each job application, highlighting the skills and experience that are most relevant to the specific role.

Essential Experience Highlights for a Strong Oakes Machine Operator Resume

- Set up and operate Oakes machines according to specifications and blueprints.

- Program CNC machines using CAM software to generate cutting paths and control machine operations.

- Perform setup reduction techniques to minimize downtime and improve efficiency.

- Monitor machine performance and make adjustments to optimize production processes.

- Inspect finished parts and ensure they meet quality standards.

- Troubleshoot and resolve machine malfunctions to minimize downtime.

- Maintain a clean and organized work area, adhering to safety protocols.

Frequently Asked Questions (FAQ’s) For Oakes Machine Operator

What is the role of an Oakes Machine Operator?

An Oakes Machine Operator is responsible for setting up, operating, and maintaining Oakes machines, which are used to cut and shape metal parts. They use CNC (Computer Numerical Control) programming to generate cutting paths and control machine operations, ensuring precision and accuracy in the production of parts.

What are the key skills required for an Oakes Machine Operator?

Key skills for an Oakes Machine Operator include Oakes Machine Operation, CNC Programming, Setup Reduction, Quality Control, and Machine Maintenance. They should also have strong attention to detail, problem-solving abilities, and a commitment to safety.

What are the career prospects for an Oakes Machine Operator?

Oakes Machine Operators can advance to roles such as CNC Programmer, Manufacturing Supervisor, or Production Manager. With additional training and experience, they can also become certified in specific areas, such as Six Sigma or Lean Manufacturing.

How can I become an Oakes Machine Operator?

To become an Oakes Machine Operator, you can pursue an Associate’s Degree in Manufacturing Technology or a related field. You can also gain experience through apprenticeships or on-the-job training programs offered by manufacturing companies.

What is the work environment like for an Oakes Machine Operator?

Oakes Machine Operators typically work in manufacturing facilities, operating machines in a production environment. They may work independently or as part of a team, and may be required to work shifts, including evenings and weekends.

What are the safety precautions that Oakes Machine Operators must follow?

Oakes Machine Operators must follow strict safety protocols to minimize the risk of accidents. This includes wearing appropriate safety gear, such as gloves, safety glasses, and earplugs, and adhering to lockout/tagout procedures when performing maintenance or repairs.