Are you a seasoned Offset Duplicating Machine Operator seeking a new career path? Discover our professionally built Offset Duplicating Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

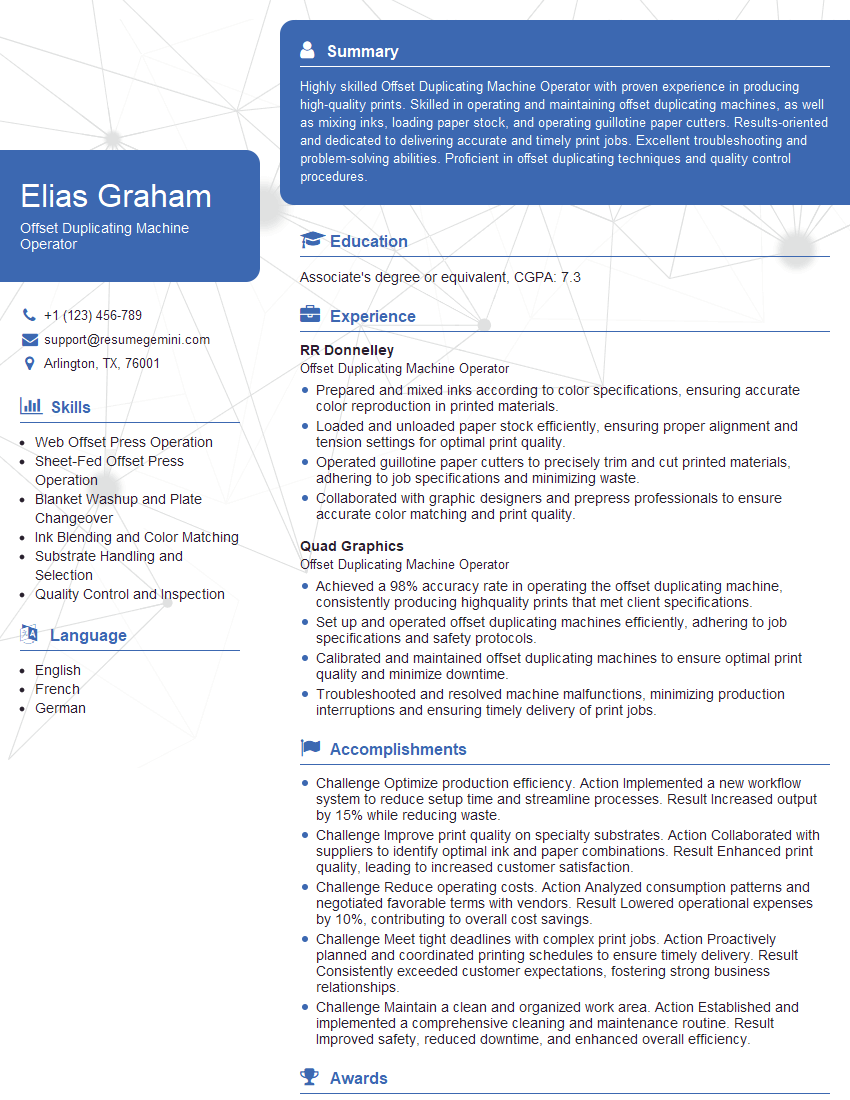

Elias Graham

Offset Duplicating Machine Operator

Summary

Highly skilled Offset Duplicating Machine Operator with proven experience in producing high-quality prints. Skilled in operating and maintaining offset duplicating machines, as well as mixing inks, loading paper stock, and operating guillotine paper cutters. Results-oriented and dedicated to delivering accurate and timely print jobs. Excellent troubleshooting and problem-solving abilities. Proficient in offset duplicating techniques and quality control procedures.

Education

Associate’s degree or equivalent

October 2015

Skills

- Web Offset Press Operation

- Sheet-Fed Offset Press Operation

- Blanket Washup and Plate Changeover

- Ink Blending and Color Matching

- Substrate Handling and Selection

- Quality Control and Inspection

Work Experience

Offset Duplicating Machine Operator

- Prepared and mixed inks according to color specifications, ensuring accurate color reproduction in printed materials.

- Loaded and unloaded paper stock efficiently, ensuring proper alignment and tension settings for optimal print quality.

- Operated guillotine paper cutters to precisely trim and cut printed materials, adhering to job specifications and minimizing waste.

- Collaborated with graphic designers and prepress professionals to ensure accurate color matching and print quality.

Offset Duplicating Machine Operator

- Achieved a 98% accuracy rate in operating the offset duplicating machine, consistently producing highquality prints that met client specifications.

- Set up and operated offset duplicating machines efficiently, adhering to job specifications and safety protocols.

- Calibrated and maintained offset duplicating machines to ensure optimal print quality and minimize downtime.

- Troubleshooted and resolved machine malfunctions, minimizing production interruptions and ensuring timely delivery of print jobs.

Accomplishments

- Challenge Optimize production efficiency. Action Implemented a new workflow system to reduce setup time and streamline processes. Result Increased output by 15% while reducing waste.

- Challenge Improve print quality on specialty substrates. Action Collaborated with suppliers to identify optimal ink and paper combinations. Result Enhanced print quality, leading to increased customer satisfaction.

- Challenge Reduce operating costs. Action Analyzed consumption patterns and negotiated favorable terms with vendors. Result Lowered operational expenses by 10%, contributing to overall cost savings.

- Challenge Meet tight deadlines with complex print jobs. Action Proactively planned and coordinated printing schedules to ensure timely delivery. Result Consistently exceeded customer expectations, fostering strong business relationships.

- Challenge Maintain a clean and organized work area. Action Established and implemented a comprehensive cleaning and maintenance routine. Result Improved safety, reduced downtime, and enhanced overall efficiency.

Awards

- Received the Offset Duplicating Machine Operator of the Year award for outstanding performance and efficiency.

- Honored with the Excellence in Offset Duplication award for consistent highquality output and innovative techniques.

- Recognized with the Safety Star award for adhering to all safety protocols and maintaining a hazardfree work environment.

Certificates

- Offset Printing Press Operator Certification

- Color Management Certification

- Press Safety Certification

- Printing and Finishing Specialist Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Offset Duplicating Machine Operator

- Highlight your experience in operating offset duplicating machines and related equipment.

- Provide specific examples of your troubleshooting and problem-solving skills.

- Quantify your accomplishments, such as your accuracy rate or the number of print jobs you produced.

- Tailor your resume to each job you apply for, highlighting the skills and experience that are most relevant to the position.

- Proofread your resume carefully for any errors before submitting it.

Essential Experience Highlights for a Strong Offset Duplicating Machine Operator Resume

- Set up and operate offset duplicating machines according to job specifications and safety protocols

- Calibrate and maintain offset duplicating machines to ensure optimal print quality and minimize downtime

- Troubleshoot and resolve machine malfunctions, minimizing production interruptions and ensuring timely delivery of print jobs

- Prepare and mix inks according to color specifications, ensuring accurate color reproduction in printed materials

- Load and unload paper stock efficiently, ensuring proper alignment and tension settings for optimal print quality

- Operate guillotine paper cutters to precisely trim and cut printed materials, adhering to job specifications and minimizing waste

- Collaborate with graphic designers and prepress professionals to ensure accurate color matching and print quality

Frequently Asked Questions (FAQ’s) For Offset Duplicating Machine Operator

What are the key skills required to be an Offset Duplicating Machine Operator?

The key skills required for an Offset Duplicating Machine Operator include operating and maintaining offset duplicating machines, understanding color theory and ink mixing, setting up and adjusting machines for different print jobs, and troubleshooting and resolving machine malfunctions.

What is the work environment of an Offset Duplicating Machine Operator like?

An Offset Duplicating Machine Operator typically works in a printing plant or a commercial print shop. The work environment can be fast-paced and demanding, and may involve working with hazardous materials such as inks and chemicals.

What are the career prospects for an Offset Duplicating Machine Operator?

Offset Duplicating Machine Operators can advance to positions such as printing press operator, prepress technician, or quality control inspector. With additional training and experience, they may also become supervisors or managers in the printing industry.

How do I become an Offset Duplicating Machine Operator?

To become an Offset Duplicating Machine Operator, you can complete a formal training program or apprenticeship, or gain experience working as an assistant or helper in a printing plant. Certification is not required, but it can demonstrate your skills and knowledge to potential employers.

What are the salary expectations for an Offset Duplicating Machine Operator?

The salary expectations for an Offset Duplicating Machine Operator vary depending on their experience, skills, and location. According to the U.S. Bureau of Labor Statistics, the median annual wage for printing press operators was $44,240 in May 2021.

What are the job duties of an Offset Duplicating Machine Operator?

The job duties of an Offset Duplicating Machine Operator include setting up and operating offset duplicating machines, calibrating and maintaining machines, troubleshooting and resolving machine malfunctions, preparing and mixing inks, loading and unloading paper stock, and operating guillotine paper cutters.

What are the safety precautions that an Offset Duplicating Machine Operator should take?

Offset Duplicating Machine Operators should follow all safety protocols and procedures, including wearing appropriate personal protective equipment (PPE), such as safety glasses, gloves, and hearing protection.