Are you a seasoned Offset Lithographic Press Operator seeking a new career path? Discover our professionally built Offset Lithographic Press Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

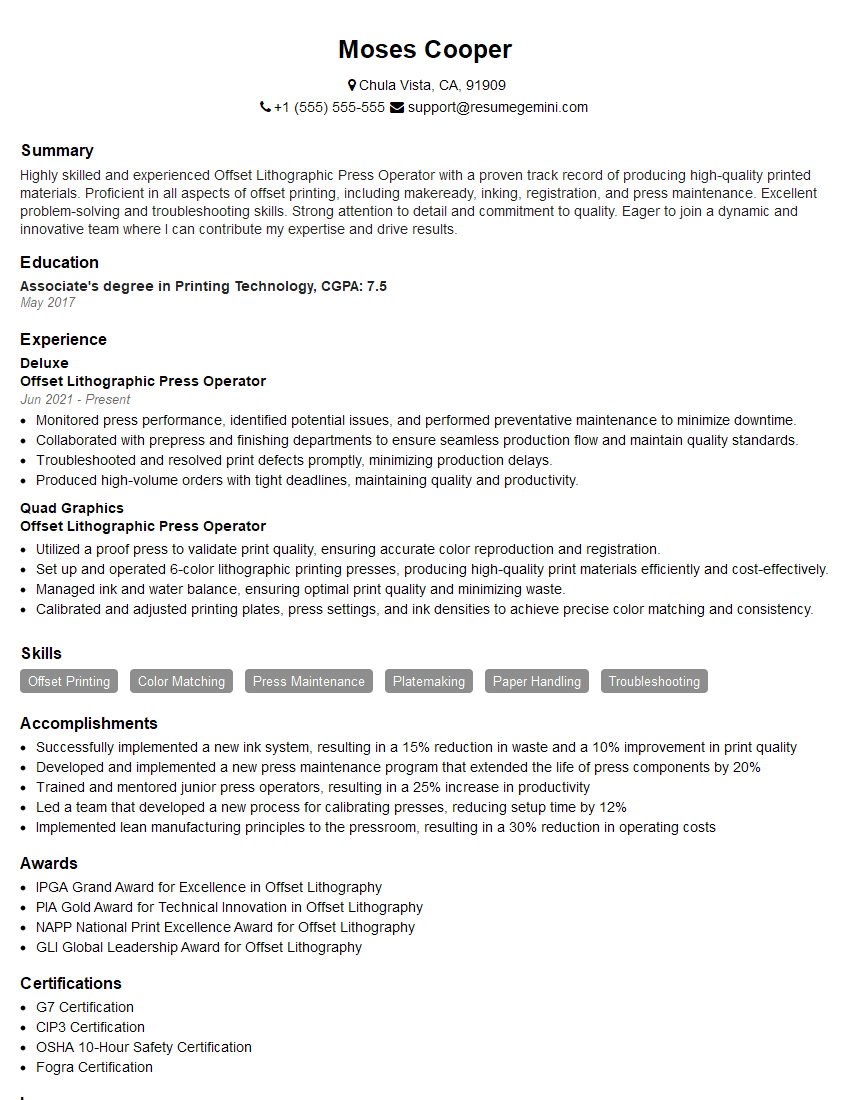

Moses Cooper

Offset Lithographic Press Operator

Summary

Highly skilled and experienced Offset Lithographic Press Operator with a proven track record of producing high-quality printed materials. Proficient in all aspects of offset printing, including makeready, inking, registration, and press maintenance. Excellent problem-solving and troubleshooting skills. Strong attention to detail and commitment to quality. Eager to join a dynamic and innovative team where I can contribute my expertise and drive results.

Education

Associate’s degree in Printing Technology

May 2017

Skills

- Offset Printing

- Color Matching

- Press Maintenance

- Platemaking

- Paper Handling

- Troubleshooting

Work Experience

Offset Lithographic Press Operator

- Monitored press performance, identified potential issues, and performed preventative maintenance to minimize downtime.

- Collaborated with prepress and finishing departments to ensure seamless production flow and maintain quality standards.

- Troubleshooted and resolved print defects promptly, minimizing production delays.

- Produced high-volume orders with tight deadlines, maintaining quality and productivity.

Offset Lithographic Press Operator

- Utilized a proof press to validate print quality, ensuring accurate color reproduction and registration.

- Set up and operated 6-color lithographic printing presses, producing high-quality print materials efficiently and cost-effectively.

- Managed ink and water balance, ensuring optimal print quality and minimizing waste.

- Calibrated and adjusted printing plates, press settings, and ink densities to achieve precise color matching and consistency.

Accomplishments

- Successfully implemented a new ink system, resulting in a 15% reduction in waste and a 10% improvement in print quality

- Developed and implemented a new press maintenance program that extended the life of press components by 20%

- Trained and mentored junior press operators, resulting in a 25% increase in productivity

- Led a team that developed a new process for calibrating presses, reducing setup time by 12%

- Implemented lean manufacturing principles to the pressroom, resulting in a 30% reduction in operating costs

Awards

- IPGA Grand Award for Excellence in Offset Lithography

- PIA Gold Award for Technical Innovation in Offset Lithography

- NAPP National Print Excellence Award for Offset Lithography

- GLI Global Leadership Award for Offset Lithography

Certificates

- G7 Certification

- CIP3 Certification

- OSHA 10-Hour Safety Certification

- Fogra Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Offset Lithographic Press Operator

- Highlight your experience operating and maintaining offset lithographic printing presses.

- Demonstrate your proficiency in makeready, inking, registration, and press maintenance.

- Showcase your problem-solving and troubleshooting skills.

- Emphasize your attention to detail and commitment to producing high-quality printed materials.

Essential Experience Highlights for a Strong Offset Lithographic Press Operator Resume

- Operate and maintain offset lithographic printing presses to produce a wide range of printed materials, such as brochures, magazines, packaging, and labels.

- Perform makeready operations, including loading paper, adjusting ink levels, and setting registration.

- Monitor print quality and make adjustments to ensure that printed materials meet customer specifications.

- Troubleshoot and resolve printing problems, such as ink smudging, paper jams, and color matching issues.

- Perform routine maintenance on printing presses to ensure optimal performance.

- Collaborate with other members of the printing team to ensure efficient production and meet deadlines.

Frequently Asked Questions (FAQ’s) For Offset Lithographic Press Operator

What are the key skills required for an Offset Lithographic Press Operator?

The key skills required for an Offset Lithographic Press Operator include offset printing, color matching, press maintenance, platemaking, paper handling, and troubleshooting.

What are the typical job responsibilities of an Offset Lithographic Press Operator?

Typical job responsibilities of an Offset Lithographic Press Operator include operating and maintaining offset lithographic printing presses, performing makeready operations, monitoring print quality, troubleshooting printing problems, and performing routine maintenance on printing presses.

What is the average salary for an Offset Lithographic Press Operator?

The average salary for an Offset Lithographic Press Operator in the United States is around $50,000 per year.

What is the job outlook for Offset Lithographic Press Operators?

The job outlook for Offset Lithographic Press Operators is expected to decline over the next few years due to automation and advances in digital printing technology.

What are the educational requirements for an Offset Lithographic Press Operator?

Most Offset Lithographic Press Operators have a high school diploma or equivalent, although some may have an associate’s degree in printing technology.

What are the certification requirements for an Offset Lithographic Press Operator?

There are no specific certification requirements for Offset Lithographic Press Operators, but some employers may prefer candidates who have completed industry-recognized training programs.