Are you a seasoned Oliver Filter Operator seeking a new career path? Discover our professionally built Oliver Filter Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

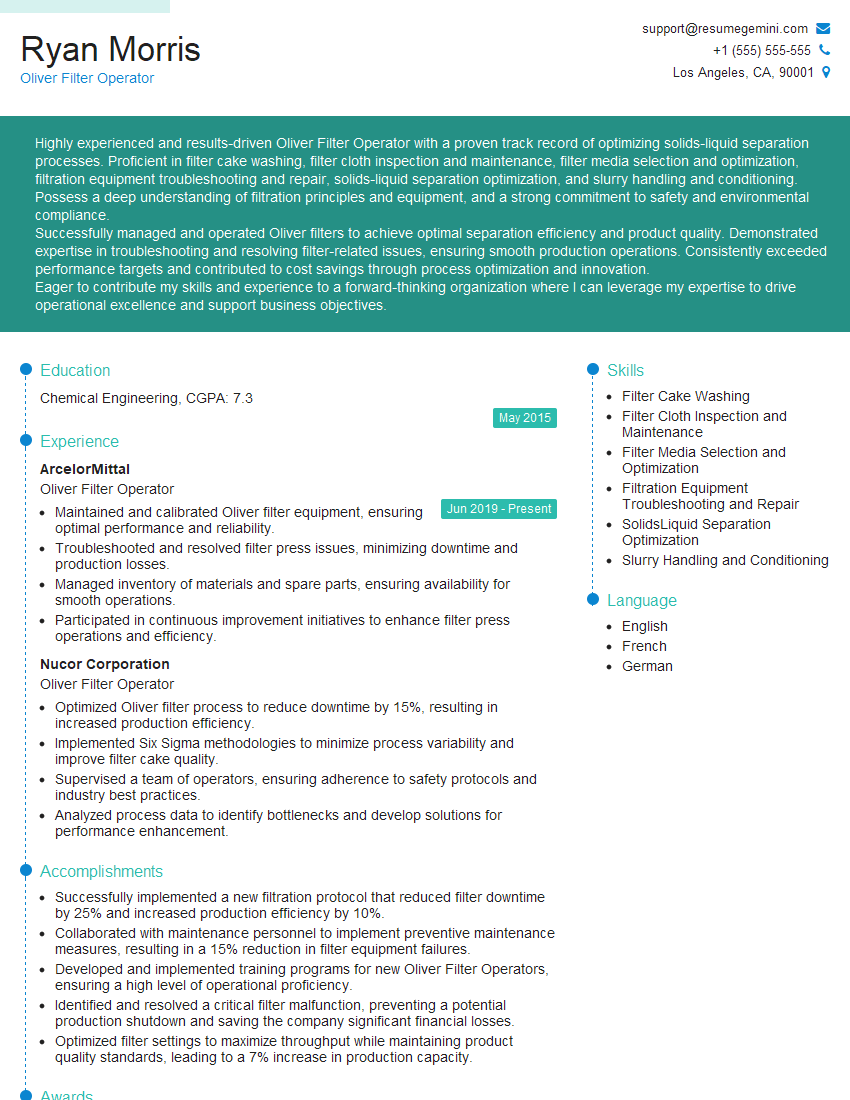

Ryan Morris

Oliver Filter Operator

Summary

Highly experienced and results-driven Oliver Filter Operator with a proven track record of optimizing solids-liquid separation processes. Proficient in filter cake washing, filter cloth inspection and maintenance, filter media selection and optimization, filtration equipment troubleshooting and repair, solids-liquid separation optimization, and slurry handling and conditioning. Possess a deep understanding of filtration principles and equipment, and a strong commitment to safety and environmental compliance.

Successfully managed and operated Oliver filters to achieve optimal separation efficiency and product quality. Demonstrated expertise in troubleshooting and resolving filter-related issues, ensuring smooth production operations. Consistently exceeded performance targets and contributed to cost savings through process optimization and innovation.

Eager to contribute my skills and experience to a forward-thinking organization where I can leverage my expertise to drive operational excellence and support business objectives.

Education

Chemical Engineering

May 2015

Skills

- Filter Cake Washing

- Filter Cloth Inspection and Maintenance

- Filter Media Selection and Optimization

- Filtration Equipment Troubleshooting and Repair

- SolidsLiquid Separation Optimization

- Slurry Handling and Conditioning

Work Experience

Oliver Filter Operator

- Maintained and calibrated Oliver filter equipment, ensuring optimal performance and reliability.

- Troubleshooted and resolved filter press issues, minimizing downtime and production losses.

- Managed inventory of materials and spare parts, ensuring availability for smooth operations.

- Participated in continuous improvement initiatives to enhance filter press operations and efficiency.

Oliver Filter Operator

- Optimized Oliver filter process to reduce downtime by 15%, resulting in increased production efficiency.

- Implemented Six Sigma methodologies to minimize process variability and improve filter cake quality.

- Supervised a team of operators, ensuring adherence to safety protocols and industry best practices.

- Analyzed process data to identify bottlenecks and develop solutions for performance enhancement.

Accomplishments

- Successfully implemented a new filtration protocol that reduced filter downtime by 25% and increased production efficiency by 10%.

- Collaborated with maintenance personnel to implement preventive maintenance measures, resulting in a 15% reduction in filter equipment failures.

- Developed and implemented training programs for new Oliver Filter Operators, ensuring a high level of operational proficiency.

- Identified and resolved a critical filter malfunction, preventing a potential production shutdown and saving the company significant financial losses.

- Optimized filter settings to maximize throughput while maintaining product quality standards, leading to a 7% increase in production capacity.

Awards

- Received the Outstanding Oliver Filter Operator Award for exceptional performance in optimizing filter operations.

- Recognized with the Plant Safety Award for maintaining a hazardfree and compliant filtration area.

- Honored with the Employee of the Month Award for consistently exceeding performance expectations and promoting a positive work environment.

- Awarded the Innovation Award for developing a novel approach to filter maintenance that significantly reduced labor costs.

Certificates

- Certified Filter Operator (CFO)

- Certified Maintenance and Reliability Technician (CMRT)

- OSHA Safety Certification

- Certified Lean Six Sigma Green Belt

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Oliver Filter Operator

- Quantify your accomplishments: Use specific metrics and data to demonstrate the impact of your work, such as increased filtration efficiency, reduced downtime, or cost savings.

- Highlight your problem-solving abilities: Describe instances where you successfully troubleshoot and resolved filter-related issues, showcasing your analytical and technical skills.

- Emphasize your commitment to safety and compliance: State your adherence to safety protocols and environmental regulations, demonstrating your responsible and professional approach.

- Tailor your resume to the specific job description: Carefully review the job requirements and tailor your resume to highlight the skills and experience that align with the position.

Essential Experience Highlights for a Strong Oliver Filter Operator Resume

- Operate and maintain Oliver filters to separate solids from liquids, ensuring optimal filtration efficiency and product quality.

- Wash filter cakes thoroughly to remove residual solids and impurities, maintaining product quality and preventing filter clogging.

- Inspect and maintain filter cloths regularly, identifying and repairing any tears or damage to prevent leaks and ensure proper filtration.

- Select and optimize filter media based on process requirements, ensuring efficient solids-liquid separation and minimizing operating costs.

- Troubleshoot and repair filtration equipment promptly, minimizing downtime and maintaining production efficiency.

- Optimize solids-liquid separation processes to improve filtration performance, reduce energy consumption, and minimize waste.

- Handle and condition slurries effectively, ensuring proper flowability and preventing filter blockages.

Frequently Asked Questions (FAQ’s) For Oliver Filter Operator

What is the role of an Oliver Filter Operator?

An Oliver Filter Operator is responsible for operating and maintaining Oliver filters, which are used to separate solids from liquids in various industrial processes. They ensure optimal filtration efficiency and product quality by performing tasks such as filter cake washing, filter cloth inspection and maintenance, filter media selection and optimization, filtration equipment troubleshooting and repair, and solids-liquid separation optimization.

What skills are required to be an Oliver Filter Operator?

Essential skills for an Oliver Filter Operator include proficiency in filter cake washing, filter cloth inspection and maintenance, filter media selection and optimization, filtration equipment troubleshooting and repair, solids-liquid separation optimization, slurry handling and conditioning, and a strong understanding of filtration principles and equipment.

What industries employ Oliver Filter Operators?

Oliver Filter Operators are employed in various industries that require solids-liquid separation processes, such as mining, chemical processing, food and beverage production, wastewater treatment, and pharmaceuticals.

What is the career path for an Oliver Filter Operator?

With experience and additional training, Oliver Filter Operators can advance to roles such as Filtration Supervisor, Process Engineer, or Plant Manager. They can also specialize in specific areas of filtration, such as membrane filtration or industrial wastewater treatment.

What is the job outlook for Oliver Filter Operators?

The job outlook for Oliver Filter Operators is expected to be stable in the coming years due to the increasing demand for filtration processes in various industries. As technology advances and new filtration methods emerge, skilled operators will be required to maintain and operate these systems.

What are the challenges faced by Oliver Filter Operators?

Common challenges faced by Oliver Filter Operators include maintaining optimal filtration efficiency, troubleshooting and resolving equipment issues, ensuring product quality, and adhering to safety and environmental regulations. They must also stay updated with the latest filtration technologies and best practices to maximize performance and minimize downtime.

What is the salary range for Oliver Filter Operators?

The salary range for Oliver Filter Operators varies depending on factors such as experience, location, and industry. According to Indeed, the average salary for Oliver Filter Operators in the United States is approximately $60,000 per year.