Are you a seasoned Operational Test Mechanic seeking a new career path? Discover our professionally built Operational Test Mechanic Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

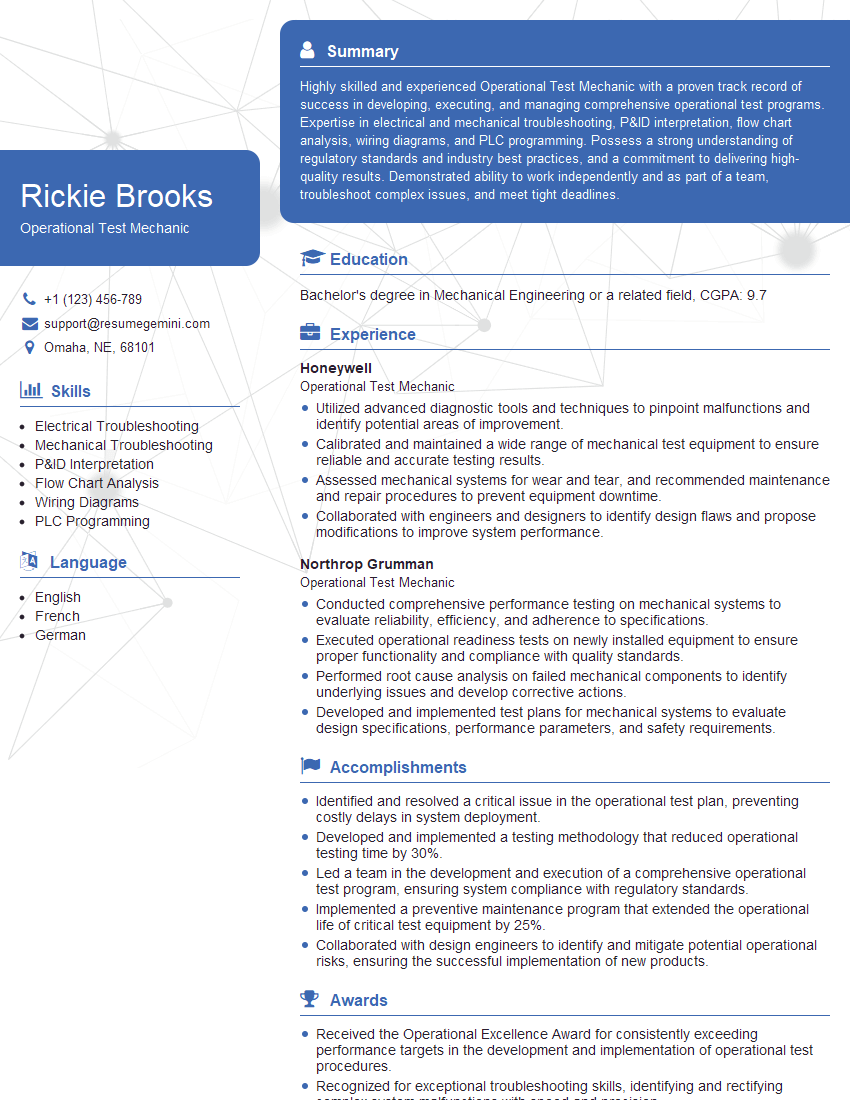

Rickie Brooks

Operational Test Mechanic

Summary

Highly skilled and experienced Operational Test Mechanic with a proven track record of success in developing, executing, and managing comprehensive operational test programs. Expertise in electrical and mechanical troubleshooting, P&ID interpretation, flow chart analysis, wiring diagrams, and PLC programming. Possess a strong understanding of regulatory standards and industry best practices, and a commitment to delivering high-quality results. Demonstrated ability to work independently and as part of a team, troubleshoot complex issues, and meet tight deadlines.

Education

Bachelor’s degree in Mechanical Engineering or a related field

March 2015

Skills

- Electrical Troubleshooting

- Mechanical Troubleshooting

- P&ID Interpretation

- Flow Chart Analysis

- Wiring Diagrams

- PLC Programming

Work Experience

Operational Test Mechanic

- Utilized advanced diagnostic tools and techniques to pinpoint malfunctions and identify potential areas of improvement.

- Calibrated and maintained a wide range of mechanical test equipment to ensure reliable and accurate testing results.

- Assessed mechanical systems for wear and tear, and recommended maintenance and repair procedures to prevent equipment downtime.

- Collaborated with engineers and designers to identify design flaws and propose modifications to improve system performance.

Operational Test Mechanic

- Conducted comprehensive performance testing on mechanical systems to evaluate reliability, efficiency, and adherence to specifications.

- Executed operational readiness tests on newly installed equipment to ensure proper functionality and compliance with quality standards.

- Performed root cause analysis on failed mechanical components to identify underlying issues and develop corrective actions.

- Developed and implemented test plans for mechanical systems to evaluate design specifications, performance parameters, and safety requirements.

Accomplishments

- Identified and resolved a critical issue in the operational test plan, preventing costly delays in system deployment.

- Developed and implemented a testing methodology that reduced operational testing time by 30%.

- Led a team in the development and execution of a comprehensive operational test program, ensuring system compliance with regulatory standards.

- Implemented a preventive maintenance program that extended the operational life of critical test equipment by 25%.

- Collaborated with design engineers to identify and mitigate potential operational risks, ensuring the successful implementation of new products.

Awards

- Received the Operational Excellence Award for consistently exceeding performance targets in the development and implementation of operational test procedures.

- Recognized for exceptional troubleshooting skills, identifying and rectifying complex system malfunctions with speed and precision.

- Awarded the Technical Innovation Award for designing and constructing a novel test fixture that significantly improved product reliability.

- Received the Safety Excellence Award for adhering to strict safety protocols and maintaining a safe working environment.

Certificates

- Certified Maintenance and Reliability Technician (CMRT)

- Certified Maintenance Professional (CMP)

- Control Systems Technician (CST)

- ISA Certified Automation Professional (CAP)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Operational Test Mechanic

- Highlight your experience in developing and executing operational test programs, including specific examples of successful projects.

- Quantify your accomplishments with specific metrics and results, such as reducing operational testing time or extending the operational life of critical test equipment.

- Demonstrate your understanding of regulatory standards and industry best practices, and how you have applied them to your work.

- Showcase your teamwork skills and ability to lead and mentor others.

- Emphasize your commitment to continuous learning and professional development.

Essential Experience Highlights for a Strong Operational Test Mechanic Resume

- Develop and execute operational test plans and procedures to ensure system compliance with regulatory standards and design specifications.

- Troubleshoot and resolve electrical and mechanical issues to ensure optimal system performance.

- Analyze test data and identify areas for improvement, making recommendations to optimize operational efficiency.

- Collaborate with design engineers to identify and mitigate potential operational risks, ensuring the seamless implementation of new products.

- Lead and mentor a team of test technicians, providing guidance and training to develop their skills and knowledge.

- Maintain and calibrate test equipment, ensuring accuracy and reliability.

- Prepare and maintain detailed test reports and documentation, providing a comprehensive record of all testing activities.

Frequently Asked Questions (FAQ’s) For Operational Test Mechanic

What is the primary role of an Operational Test Mechanic?

The primary role of an Operational Test Mechanic is to ensure that systems and equipment meet the required specifications and standards through testing and troubleshooting.

What industries employ Operational Test Mechanics?

Operational Test Mechanics are employed in a wide range of industries, including manufacturing, aerospace, automotive, and electronics.

What are the key skills required for this role?

Key skills for an Operational Test Mechanic include electrical and mechanical troubleshooting, P&ID interpretation, flow chart analysis, wiring diagrams, PLC programming, and a strong understanding of regulatory standards.

What is the career progression path for an Operational Test Mechanic?

With experience and additional training, Operational Test Mechanics can advance to roles such as Test Engineer, Quality Assurance Manager, or Project Manager.

What are the salary expectations for this role?

Salary expectations for Operational Test Mechanics vary depending on experience, location, and industry, but typically range from $60,000 to $100,000 per year.

What are the key challenges faced by Operational Test Mechanics?

Operational Test Mechanics often face challenges such as tight deadlines, complex systems, and troubleshooting unexpected issues.