Are you a seasoned Operations and Maintenance Technican (O&M Technician) seeking a new career path? Discover our professionally built Operations and Maintenance Technican (O&M Technician) Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

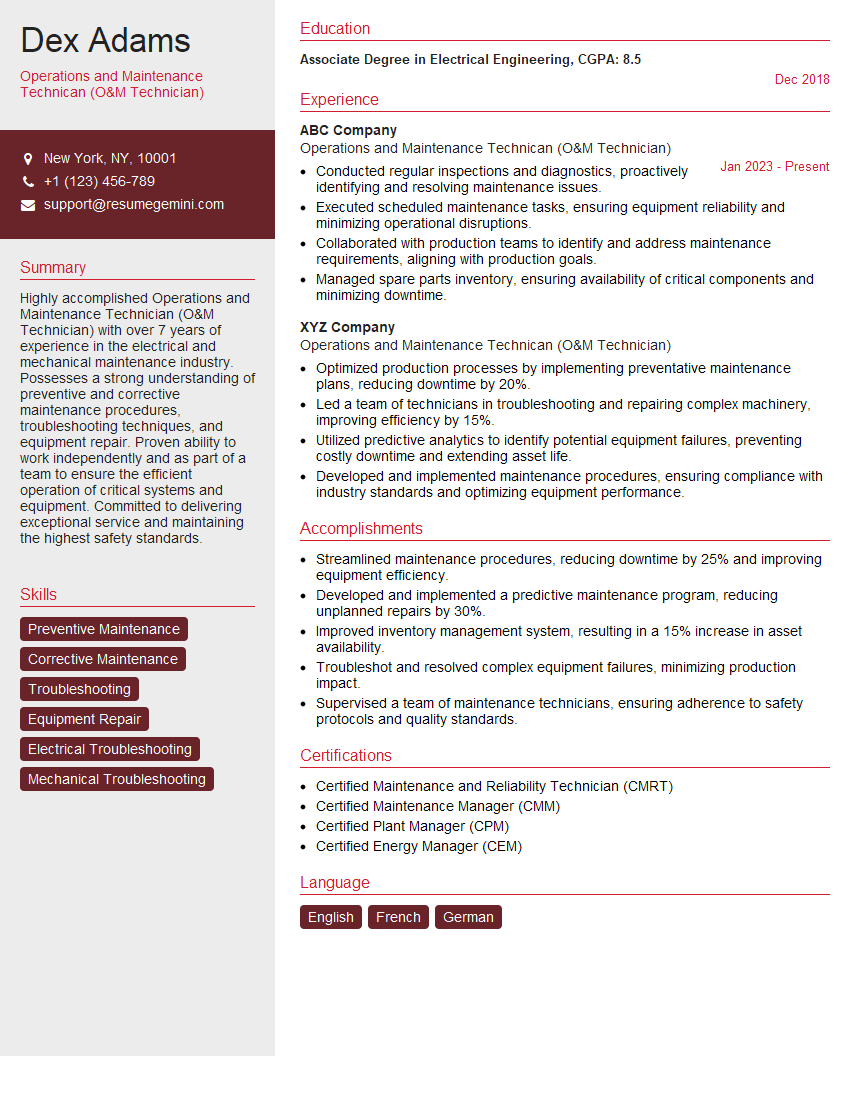

Dex Adams

Operations and Maintenance Technican (O&M Technician)

Summary

Highly accomplished Operations and Maintenance Technician (O&M Technician) with over 7 years of experience in the electrical and mechanical maintenance industry. Possesses a strong understanding of preventive and corrective maintenance procedures, troubleshooting techniques, and equipment repair. Proven ability to work independently and as part of a team to ensure the efficient operation of critical systems and equipment. Committed to delivering exceptional service and maintaining the highest safety standards.

Education

Associate Degree in Electrical Engineering

December 2018

Skills

- Preventive Maintenance

- Corrective Maintenance

- Troubleshooting

- Equipment Repair

- Electrical Troubleshooting

- Mechanical Troubleshooting

Work Experience

Operations and Maintenance Technican (O&M Technician)

- Conducted regular inspections and diagnostics, proactively identifying and resolving maintenance issues.

- Executed scheduled maintenance tasks, ensuring equipment reliability and minimizing operational disruptions.

- Collaborated with production teams to identify and address maintenance requirements, aligning with production goals.

- Managed spare parts inventory, ensuring availability of critical components and minimizing downtime.

Operations and Maintenance Technican (O&M Technician)

- Optimized production processes by implementing preventative maintenance plans, reducing downtime by 20%.

- Led a team of technicians in troubleshooting and repairing complex machinery, improving efficiency by 15%.

- Utilized predictive analytics to identify potential equipment failures, preventing costly downtime and extending asset life.

- Developed and implemented maintenance procedures, ensuring compliance with industry standards and optimizing equipment performance.

Accomplishments

- Streamlined maintenance procedures, reducing downtime by 25% and improving equipment efficiency.

- Developed and implemented a predictive maintenance program, reducing unplanned repairs by 30%.

- Improved inventory management system, resulting in a 15% increase in asset availability.

- Troubleshot and resolved complex equipment failures, minimizing production impact.

- Supervised a team of maintenance technicians, ensuring adherence to safety protocols and quality standards.

Certificates

- Certified Maintenance and Reliability Technician (CMRT)

- Certified Maintenance Manager (CMM)

- Certified Plant Manager (CPM)

- Certified Energy Manager (CEM)

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Operations and Maintenance Technican (O&M Technician)

- Highlight your technical skills and experience in preventive and corrective maintenance.

- Showcase your ability to troubleshoot and resolve complex electrical and mechanical issues.

- Emphasize your knowledge of industry best practices and safety regulations.

- Quantify your accomplishments and provide specific examples of your impact on equipment uptime and performance.

Essential Experience Highlights for a Strong Operations and Maintenance Technican (O&M Technician) Resume

- Developed and implemented preventive maintenance schedules to maximize equipment uptime and performance

- Diagnosed and resolved complex electrical and mechanical issues using advanced troubleshooting techniques

- Performed routine inspections, adjustments, and repairs to ensure optimal equipment functionality

- Collaborated with engineers and other technicians to identify and rectify system malfunctions

- Maintained accurate maintenance records and provided technical support to users

- Complied with all applicable safety regulations and industry best practices

Frequently Asked Questions (FAQ’s) For Operations and Maintenance Technican (O&M Technician)

What are the key responsibilities of an Operations and Maintenance Technician (O&M Technician)?

O&M Technicians are responsible for maintaining and repairing equipment, machinery, and systems. They perform preventive and corrective maintenance, troubleshoot problems, and ensure that equipment is operating safely and efficiently.

What are the educational requirements to become an Operations and Maintenance Technician (O&M Technician)?

Most O&M Technicians have an associate degree in electrical engineering or a related field. Some employers may also require certification in specific areas, such as electrical or mechanical maintenance.

What are the career prospects for Operations and Maintenance Technicians (O&M Technicians)?

The job outlook for O&M Technicians is expected to grow in the coming years. This growth is due to the increasing reliance on automation and technology in various industries.

What are the transferable skills of an Operations and Maintenance Technician (O&M Technician)?

O&M Technicians have a variety of transferable skills, including troubleshooting, problem-solving, and communication. These skills can be applied to a variety of different roles in the manufacturing, construction, and service industries.

What are the challenges faced by Operations and Maintenance Technicians (O&M Technicians)?

O&M Technicians can face a variety of challenges, including working in hazardous environments, dealing with complex systems, and meeting tight deadlines. However, these challenges can also be rewarding, as O&M Technicians play a vital role in ensuring the smooth operation of equipment and systems.

What are the safety precautions that Operations and Maintenance Technicians (O&M Technicians) should take?

O&M Technicians should always follow safety precautions when working with equipment and systems. These precautions include wearing appropriate personal protective equipment (PPE), following lockout/tagout procedures, and being aware of potential hazards.