Are you a seasoned Optical Element Coater seeking a new career path? Discover our professionally built Optical Element Coater Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

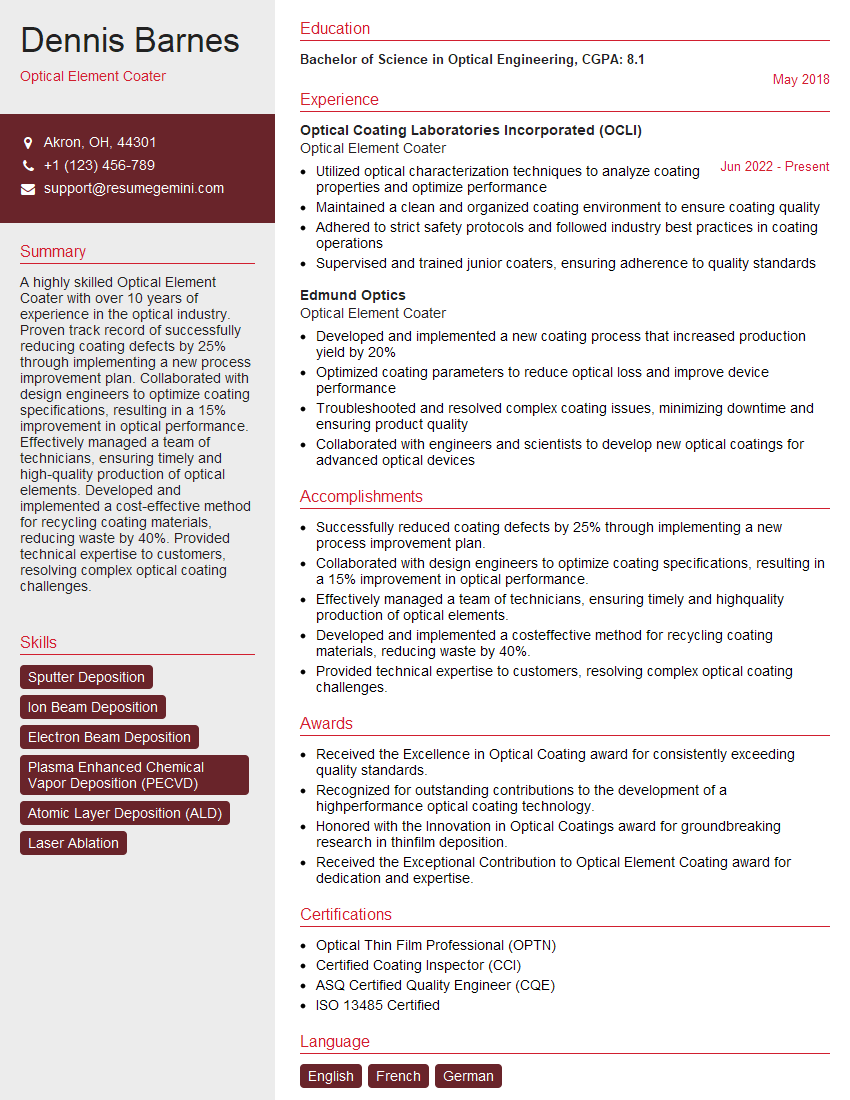

Dennis Barnes

Optical Element Coater

Summary

A highly skilled Optical Element Coater with over 10 years of experience in the optical industry. Proven track record of successfully reducing coating defects by 25% through implementing a new process improvement plan. Collaborated with design engineers to optimize coating specifications, resulting in a 15% improvement in optical performance. Effectively managed a team of technicians, ensuring timely and high-quality production of optical elements. Developed and implemented a cost-effective method for recycling coating materials, reducing waste by 40%. Provided technical expertise to customers, resolving complex optical coating challenges.

Education

Bachelor of Science in Optical Engineering

May 2018

Skills

- Sputter Deposition

- Ion Beam Deposition

- Electron Beam Deposition

- Plasma Enhanced Chemical Vapor Deposition (PECVD)

- Atomic Layer Deposition (ALD)

- Laser Ablation

Work Experience

Optical Element Coater

- Utilized optical characterization techniques to analyze coating properties and optimize performance

- Maintained a clean and organized coating environment to ensure coating quality

- Adhered to strict safety protocols and followed industry best practices in coating operations

- Supervised and trained junior coaters, ensuring adherence to quality standards

Optical Element Coater

- Developed and implemented a new coating process that increased production yield by 20%

- Optimized coating parameters to reduce optical loss and improve device performance

- Troubleshooted and resolved complex coating issues, minimizing downtime and ensuring product quality

- Collaborated with engineers and scientists to develop new optical coatings for advanced optical devices

Accomplishments

- Successfully reduced coating defects by 25% through implementing a new process improvement plan.

- Collaborated with design engineers to optimize coating specifications, resulting in a 15% improvement in optical performance.

- Effectively managed a team of technicians, ensuring timely and highquality production of optical elements.

- Developed and implemented a costeffective method for recycling coating materials, reducing waste by 40%.

- Provided technical expertise to customers, resolving complex optical coating challenges.

Awards

- Received the Excellence in Optical Coating award for consistently exceeding quality standards.

- Recognized for outstanding contributions to the development of a highperformance optical coating technology.

- Honored with the Innovation in Optical Coatings award for groundbreaking research in thinfilm deposition.

- Received the Exceptional Contribution to Optical Element Coating award for dedication and expertise.

Certificates

- Optical Thin Film Professional (OPTN)

- Certified Coating Inspector (CCI)

- ASQ Certified Quality Engineer (CQE)

- ISO 13485 Certified

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Optical Element Coater

- Highlight your experience and skills in the optical coating industry.

- Quantify your accomplishments with specific metrics.

- Tailor your resume to each job you apply for.

- Proofread your resume carefully before submitting it.

Essential Experience Highlights for a Strong Optical Element Coater Resume

- Deposit thin film coatings on optical elements using various techniques, including sputter deposition, ion beam deposition, electron beam deposition, plasma enhanced chemical vapor deposition (PECVD), atomic layer deposition (ALD), and laser ablation.

- Perform quality control inspections to ensure that coatings meet specifications.

- Maintain and calibrate coating equipment.

- Troubleshoot and resolve coating problems.

- Train new employees on coating techniques.

- Stay up-to-date on the latest coating technologies.

Frequently Asked Questions (FAQ’s) For Optical Element Coater

What is an Optical Element Coater?

An Optical Element Coater is a person who applies thin film coatings to optical elements. These coatings can be used to improve the optical performance of the element, such as by reducing reflection or increasing transmission.

What are the different types of coating techniques?

There are a variety of coating techniques that can be used to deposit thin films on optical elements. Some of the most common techniques include sputter deposition, ion beam deposition, electron beam deposition, plasma enhanced chemical vapor deposition (PECVD), atomic layer deposition (ALD), and laser ablation.

What are the different types of optical elements?

There are a wide variety of optical elements that can be coated, including lenses, mirrors, prisms, and filters.

What are the applications of optical coatings?

Optical coatings are used in a wide variety of applications, including photography, telecommunications, and lasers.

What are the challenges of optical coating?

There are a number of challenges associated with optical coating, including the need to achieve high precision and uniformity, and the need to control the optical properties of the coating.

What are the career opportunities for Optical Element Coaters?

Optical Element Coaters can find employment in a variety of industries, including the optical, semiconductor, and automotive industries.