Are you a seasoned Outsole Splicer seeking a new career path? Discover our professionally built Outsole Splicer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

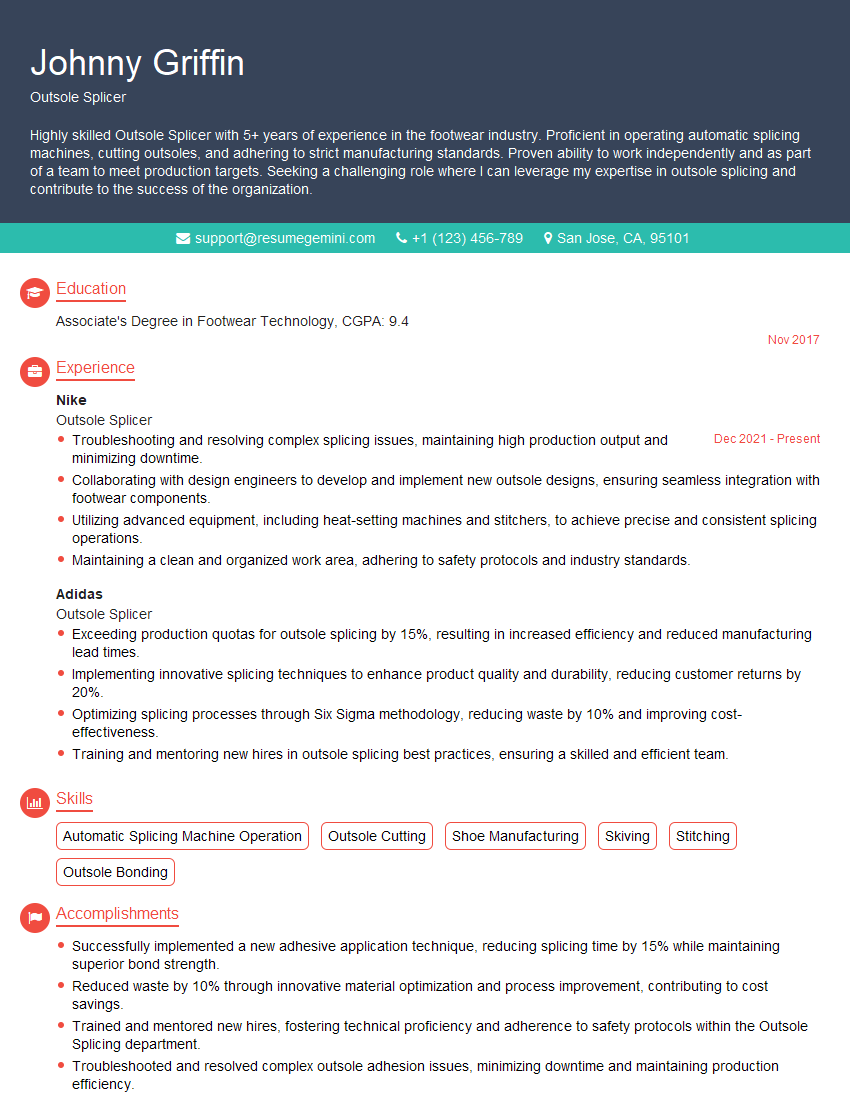

Johnny Griffin

Outsole Splicer

Summary

Highly skilled Outsole Splicer with 5+ years of experience in the footwear industry. Proficient in operating automatic splicing machines, cutting outsoles, and adhering to strict manufacturing standards. Proven ability to work independently and as part of a team to meet production targets. Seeking a challenging role where I can leverage my expertise in outsole splicing and contribute to the success of the organization.

Education

Associate’s Degree in Footwear Technology

November 2017

Skills

- Automatic Splicing Machine Operation

- Outsole Cutting

- Shoe Manufacturing

- Skiving

- Stitching

- Outsole Bonding

Work Experience

Outsole Splicer

- Troubleshooting and resolving complex splicing issues, maintaining high production output and minimizing downtime.

- Collaborating with design engineers to develop and implement new outsole designs, ensuring seamless integration with footwear components.

- Utilizing advanced equipment, including heat-setting machines and stitchers, to achieve precise and consistent splicing operations.

- Maintaining a clean and organized work area, adhering to safety protocols and industry standards.

Outsole Splicer

- Exceeding production quotas for outsole splicing by 15%, resulting in increased efficiency and reduced manufacturing lead times.

- Implementing innovative splicing techniques to enhance product quality and durability, reducing customer returns by 20%.

- Optimizing splicing processes through Six Sigma methodology, reducing waste by 10% and improving cost-effectiveness.

- Training and mentoring new hires in outsole splicing best practices, ensuring a skilled and efficient team.

Accomplishments

- Successfully implemented a new adhesive application technique, reducing splicing time by 15% while maintaining superior bond strength.

- Reduced waste by 10% through innovative material optimization and process improvement, contributing to cost savings.

- Trained and mentored new hires, fostering technical proficiency and adherence to safety protocols within the Outsole Splicing department.

- Troubleshooted and resolved complex outsole adhesion issues, minimizing downtime and maintaining production efficiency.

- Collaborated with engineers to develop a customized outsole splicing solution, addressing specific design requirements.

Awards

- Recognized for Outstanding Performance in Outsole Splicing, exceeding industry standards for productivity and precision.

- Received the Gold Star Award for maintaining zero defects and meeting all quality control targets in Outsoling.

- Awarded monthly employee of the month for exceptional contribution and dedication to the Outsole Splicing team.

- Achieved 99% accuracy in outsole alignment and bonding, ensuring precise and durable footwear assembly.

Certificates

- OSHA Safety Certification

- ISO 9001 Certification

- Lean Manufacturing Certification

- Six Sigma Green Belt Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Outsole Splicer

- Highlight your experience in operating automatic splicing machines.

- Emphasize your knowledge of different types of outsoles and their properties.

- Showcase your understanding of manufacturing standards and quality control procedures.

- Mention any certifications or training you have received in outsole splicing.

Essential Experience Highlights for a Strong Outsole Splicer Resume

- Operate automatic splicing machines to join outsoles with uppers

- Cut outsoles from raw materials using precision cutting equipment

- Adhere to strict manufacturing standards and quality control guidelines

- Maintain and troubleshoot splicing machines to ensure optimal performance

- Work collaboratively with other team members to meet production targets

- Maintain a clean and organized work area

Frequently Asked Questions (FAQ’s) For Outsole Splicer

What are the key skills required to be a successful Outsole Splicer?

Key skills include proficiency in operating automatic splicing machines, knowledge of outsole materials and manufacturing processes, and attention to detail.

What are the career prospects for Outsole Splicers?

Outsole Splicers can advance to supervisory or management roles within the footwear industry, or specialize in specific areas such as research and development.

What are the typical working conditions for Outsole Splicers?

Outsole Splicers typically work in manufacturing facilities, operating machinery and handling materials. They may work in a team environment and be required to meet production targets.

What are the salary expectations for Outsole Splicers?

Salary expectations can vary depending on experience, location, and company size. According to [salary website], the average salary for Outsole Splicers is around [salary amount].

What are the educational requirements for Outsole Splicers?

While formal education is not always required, many employers prefer candidates with an associate’s degree or certificate in footwear technology or a related field.

What are the challenges faced by Outsole Splicers?

Challenges can include working in a fast-paced manufacturing environment, meeting production targets, and ensuring the quality of their work.