Are you a seasoned Oxyacetylene Burner seeking a new career path? Discover our professionally built Oxyacetylene Burner Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

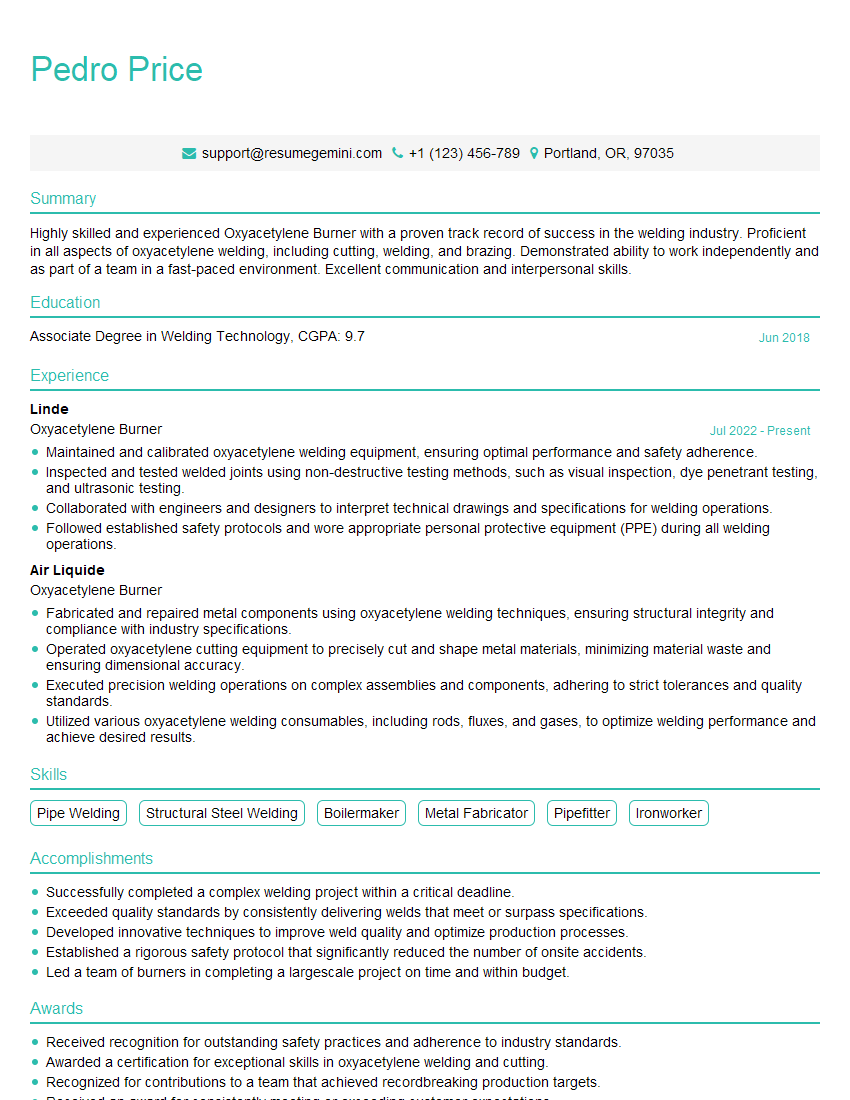

Pedro Price

Oxyacetylene Burner

Summary

Highly skilled and experienced Oxyacetylene Burner with a proven track record of success in the welding industry. Proficient in all aspects of oxyacetylene welding, including cutting, welding, and brazing. Demonstrated ability to work independently and as part of a team in a fast-paced environment. Excellent communication and interpersonal skills.

Education

Associate Degree in Welding Technology

June 2018

Skills

- Pipe Welding

- Structural Steel Welding

- Boilermaker

- Metal Fabricator

- Pipefitter

- Ironworker

Work Experience

Oxyacetylene Burner

- Maintained and calibrated oxyacetylene welding equipment, ensuring optimal performance and safety adherence.

- Inspected and tested welded joints using non-destructive testing methods, such as visual inspection, dye penetrant testing, and ultrasonic testing.

- Collaborated with engineers and designers to interpret technical drawings and specifications for welding operations.

- Followed established safety protocols and wore appropriate personal protective equipment (PPE) during all welding operations.

Oxyacetylene Burner

- Fabricated and repaired metal components using oxyacetylene welding techniques, ensuring structural integrity and compliance with industry specifications.

- Operated oxyacetylene cutting equipment to precisely cut and shape metal materials, minimizing material waste and ensuring dimensional accuracy.

- Executed precision welding operations on complex assemblies and components, adhering to strict tolerances and quality standards.

- Utilized various oxyacetylene welding consumables, including rods, fluxes, and gases, to optimize welding performance and achieve desired results.

Accomplishments

- Successfully completed a complex welding project within a critical deadline.

- Exceeded quality standards by consistently delivering welds that meet or surpass specifications.

- Developed innovative techniques to improve weld quality and optimize production processes.

- Established a rigorous safety protocol that significantly reduced the number of onsite accidents.

- Led a team of burners in completing a largescale project on time and within budget.

Awards

- Received recognition for outstanding safety practices and adherence to industry standards.

- Awarded a certification for exceptional skills in oxyacetylene welding and cutting.

- Recognized for contributions to a team that achieved recordbreaking production targets.

- Received an award for consistently meeting or exceeding customer expectations.

Certificates

- AWS Certified Welder

- ASME Boiler and Pressure Vessel Code

- National Board of Boiler and Pressure Vessel Inspectors

- Occupational Safety and Health Administration (OSHA)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Oxyacetylene Burner

- Highlight your experience and skills in oxyacetylene welding.

- Include any certifications or training you have received.

- Tailor your resume to the specific job you are applying for.

- Proofread your resume carefully before submitting it.

Essential Experience Highlights for a Strong Oxyacetylene Burner Resume

- Operate and maintain oxyacetylene welding equipment

- Cut, weld, and braze metal components according to specifications

- Inspect welds for defects and ensure they meet quality standards

- Follow safety procedures and use proper protective gear

- Maintain a clean and organized work area

- Collaborate with other tradespeople to complete projects on time and within budget

Frequently Asked Questions (FAQ’s) For Oxyacetylene Burner

What is oxyacetylene welding?

Oxyacetylene welding is a type of welding that uses a mixture of oxygen and acetylene gases to produce a flame that is used to melt metal and join it together.

What are the benefits of oxyacetylene welding?

Oxyacetylene welding is a versatile welding process that can be used to weld a wide variety of metals. It is also a relatively inexpensive welding process.

What are the safety hazards associated with oxyacetylene welding?

Oxyacetylene welding can be a hazardous process if proper safety precautions are not taken. The flames produced by oxyacetylene welding can be very hot and can cause burns. The gases used in oxyacetylene welding can also be explosive if they are not handled properly.

What are the applications of oxyacetylene welding?

Oxyacetylene welding is used in a variety of applications, including: – Cutting metal – Joining metal – Repairing metal – Fabricating metal

What are the career opportunities for oxyacetylene welders?

Oxyacetylene welders are in high demand in a variety of industries, including: – Construction – Manufacturing – Automotive – Aerospace