Are you a seasoned Oxygen Furnace Operator seeking a new career path? Discover our professionally built Oxygen Furnace Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

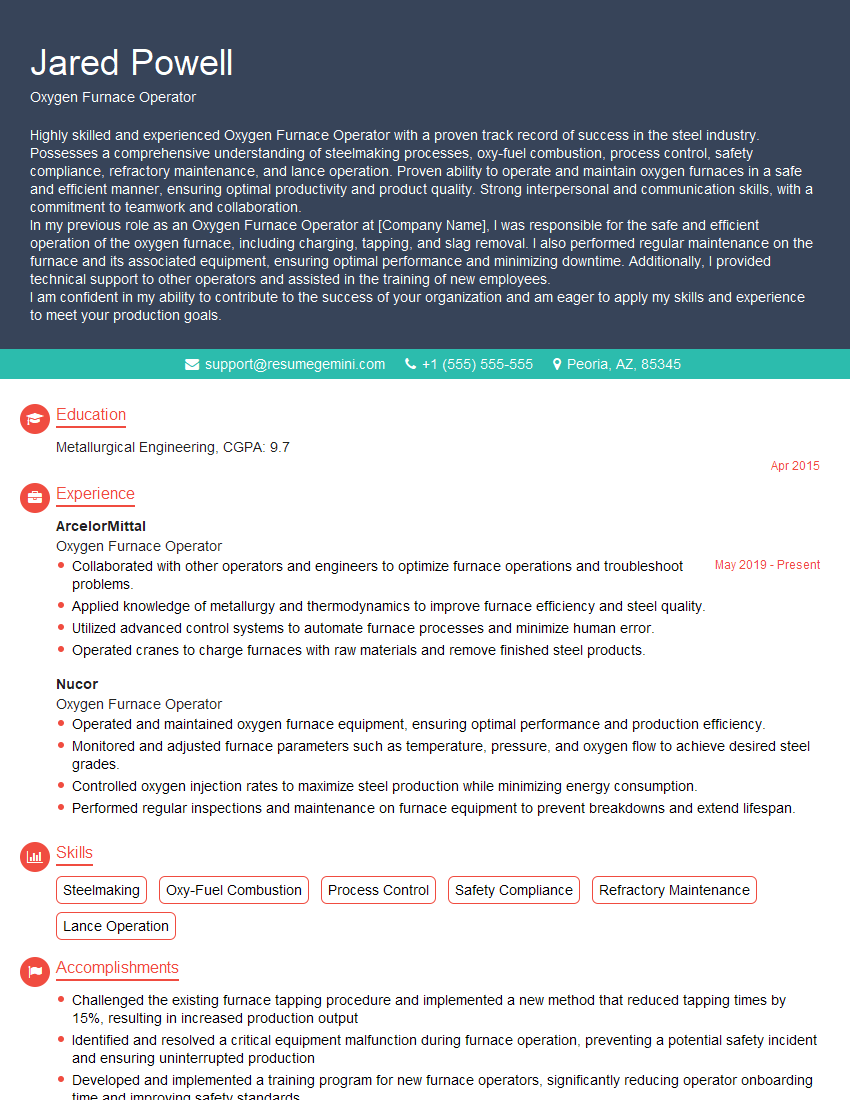

Jared Powell

Oxygen Furnace Operator

Summary

Highly skilled and experienced Oxygen Furnace Operator with a proven track record of success in the steel industry. Possesses a comprehensive understanding of steelmaking processes, oxy-fuel combustion, process control, safety compliance, refractory maintenance, and lance operation. Proven ability to operate and maintain oxygen furnaces in a safe and efficient manner, ensuring optimal productivity and product quality. Strong interpersonal and communication skills, with a commitment to teamwork and collaboration.

In my previous role as an Oxygen Furnace Operator at [Company Name], I was responsible for the safe and efficient operation of the oxygen furnace, including charging, tapping, and slag removal. I also performed regular maintenance on the furnace and its associated equipment, ensuring optimal performance and minimizing downtime. Additionally, I provided technical support to other operators and assisted in the training of new employees.

I am confident in my ability to contribute to the success of your organization and am eager to apply my skills and experience to meet your production goals.

Education

Metallurgical Engineering

April 2015

Skills

- Steelmaking

- Oxy-Fuel Combustion

- Process Control

- Safety Compliance

- Refractory Maintenance

- Lance Operation

Work Experience

Oxygen Furnace Operator

- Collaborated with other operators and engineers to optimize furnace operations and troubleshoot problems.

- Applied knowledge of metallurgy and thermodynamics to improve furnace efficiency and steel quality.

- Utilized advanced control systems to automate furnace processes and minimize human error.

- Operated cranes to charge furnaces with raw materials and remove finished steel products.

Oxygen Furnace Operator

- Operated and maintained oxygen furnace equipment, ensuring optimal performance and production efficiency.

- Monitored and adjusted furnace parameters such as temperature, pressure, and oxygen flow to achieve desired steel grades.

- Controlled oxygen injection rates to maximize steel production while minimizing energy consumption.

- Performed regular inspections and maintenance on furnace equipment to prevent breakdowns and extend lifespan.

Accomplishments

- Challenged the existing furnace tapping procedure and implemented a new method that reduced tapping times by 15%, resulting in increased production output

- Identified and resolved a critical equipment malfunction during furnace operation, preventing a potential safety incident and ensuring uninterrupted production

- Developed and implemented a training program for new furnace operators, significantly reducing operator onboarding time and improving safety standards

- Optimized furnace operating parameters to achieve a 10% reduction in energy consumption, contributing to cost savings and environmental sustainability

- Monitored and analyzed furnace performance data, identifying and implementing improvements that resulted in a 5% increase in furnace productivity

Awards

- Received the Operator of the Year award for exceptional performance and contributions to the oxygen furnace operation

- Recognized with the Safety Champion award for maintaining an exemplary safety record and promoting a positive safety culture within the furnace team

- Awarded the Innovation Award for developing and implementing a novel process that significantly improved furnace efficiency

Certificates

- Certified Oxygen Furnace Operator (COFO)

- OSHA 40-Hour HAZWOPER

- American Red Cross First Aid/CPR/AED

- National Fire Protection Association (NFPA) 10

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Oxygen Furnace Operator

- Highlight your technical skills and experience in steelmaking, oxy-fuel combustion, and process control.

- Quantify your accomplishments and provide specific examples of how you have improved productivity or reduced downtime.

- Showcase your commitment to safety and compliance by mentioning any relevant certifications or training programs.

- Emphasize your ability to work independently and as part of a team.

Essential Experience Highlights for a Strong Oxygen Furnace Operator Resume

- Operate oxygen furnaces to produce steel according to specified quality standards

- Monitor and control furnace temperature, oxygen flow, and other process parameters to optimize production efficiency

- Inspect and maintain furnace equipment, including refractory lining, lances, and nozzles

- Troubleshoot and resolve furnace operating problems to minimize downtime and ensure safe and efficient operation

- Adhere to all safety regulations and procedures to protect personnel and equipment

- Collaborate with other operators, engineers, and supervisors to optimize furnace performance and achieve production targets

- Maintain accurate records of furnace operations and performance data

Frequently Asked Questions (FAQ’s) For Oxygen Furnace Operator

What is the primary role of an Oxygen Furnace Operator?

The primary role of an Oxygen Furnace Operator is to safely and efficiently operate an oxygen furnace to produce steel according to specified quality standards.

What are the key skills required to be successful as an Oxygen Furnace Operator?

Key skills required for success as an Oxygen Furnace Operator include a strong understanding of steelmaking processes, oxy-fuel combustion, process control, safety compliance, refractory maintenance, and lance operation.

What are the career prospects for Oxygen Furnace Operators?

Oxygen Furnace Operators can advance to roles such as Production Supervisor, Plant Manager, or Technical Advisor in the steel industry.

What is the work environment like for Oxygen Furnace Operators?

Oxygen Furnace Operators typically work in a hot, noisy, and potentially hazardous environment. They must be able to work independently and as part of a team, and be able to respond quickly to emergencies.

What are the salary expectations for Oxygen Furnace Operators?

Salary expectations for Oxygen Furnace Operators can vary depending on experience, qualifications, and location.