Are you a seasoned Pallet Rectifier seeking a new career path? Discover our professionally built Pallet Rectifier Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

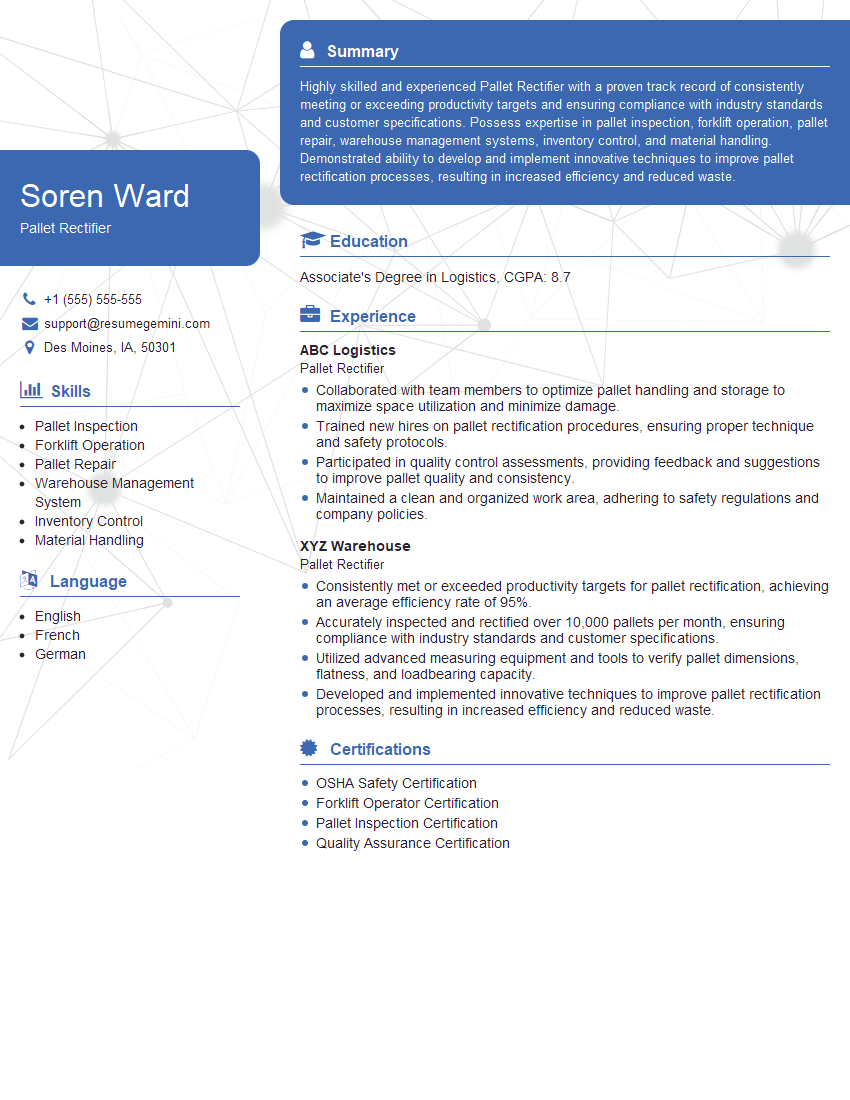

Soren Ward

Pallet Rectifier

Summary

Highly skilled and experienced Pallet Rectifier with a proven track record of consistently meeting or exceeding productivity targets and ensuring compliance with industry standards and customer specifications. Possess expertise in pallet inspection, forklift operation, pallet repair, warehouse management systems, inventory control, and material handling. Demonstrated ability to develop and implement innovative techniques to improve pallet rectification processes, resulting in increased efficiency and reduced waste.

Education

Associate’s Degree in Logistics

April 2016

Skills

- Pallet Inspection

- Forklift Operation

- Pallet Repair

- Warehouse Management System

- Inventory Control

- Material Handling

Work Experience

Pallet Rectifier

- Collaborated with team members to optimize pallet handling and storage to maximize space utilization and minimize damage.

- Trained new hires on pallet rectification procedures, ensuring proper technique and safety protocols.

- Participated in quality control assessments, providing feedback and suggestions to improve pallet quality and consistency.

- Maintained a clean and organized work area, adhering to safety regulations and company policies.

Pallet Rectifier

- Consistently met or exceeded productivity targets for pallet rectification, achieving an average efficiency rate of 95%.

- Accurately inspected and rectified over 10,000 pallets per month, ensuring compliance with industry standards and customer specifications.

- Utilized advanced measuring equipment and tools to verify pallet dimensions, flatness, and loadbearing capacity.

- Developed and implemented innovative techniques to improve pallet rectification processes, resulting in increased efficiency and reduced waste.

Certificates

- OSHA Safety Certification

- Forklift Operator Certification

- Pallet Inspection Certification

- Quality Assurance Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Pallet Rectifier

- Highlight your experience and skills in pallet inspection, forklift operation, and pallet repair.

- Quantify your accomplishments with specific metrics, such as the number of pallets rectified or the percentage of efficiency achieved.

- Showcase your knowledge of industry standards and customer specifications related to pallet rectification.

- Emphasize your ability to work independently and as part of a team.

- Proofread your resume carefully for any errors before submitting it.

Essential Experience Highlights for a Strong Pallet Rectifier Resume

- Inspect and rectify pallets to ensure compliance with industry standards and customer specifications.

- Utilize advanced measuring equipment and tools to verify pallet dimensions, flatness, and loadbearing capacity.

- Develop and implement innovative techniques to improve pallet rectification processes.

- Collaborate with team members to optimize pallet handling and storage.

- Train new hires on pallet rectification procedures.

- Participate in quality control assessments and provide feedback to improve pallet quality and consistency.

- Maintain a clean and organized work area.

Frequently Asked Questions (FAQ’s) For Pallet Rectifier

What are the key responsibilities of a Pallet Rectifier?

The key responsibilities of a Pallet Rectifier include inspecting and rectifying pallets to ensure compliance with industry standards and customer specifications, utilizing advanced measuring equipment and tools to verify pallet dimensions, flatness, and loadbearing capacity, developing and implementing innovative techniques to improve pallet rectification processes, collaborating with team members to optimize pallet handling and storage, training new hires on pallet rectification procedures, participating in quality control assessments and providing feedback to improve pallet quality and consistency, and maintaining a clean and organized work area.

What skills are required to be a Pallet Rectifier?

The skills required to be a Pallet Rectifier include pallet inspection, forklift operation, pallet repair, warehouse management system, inventory control, and material handling.

What is the work environment of a Pallet Rectifier?

Pallet Rectifiers typically work in a warehouse or manufacturing environment. They may be required to work in a variety of conditions, including extreme temperatures and noise levels.

What are the career prospects for a Pallet Rectifier?

Pallet Rectifiers can advance their careers by becoming supervisors or managers in the warehousing or manufacturing industry. They may also specialize in a particular area of pallet rectification, such as quality control or training.

What is the salary range for a Pallet Rectifier?

The salary range for a Pallet Rectifier can vary depending on experience, location, and company size. According to Salary.com, the average salary for a Pallet Rectifier in the United States is $42,000 per year.

What are the benefits of working as a Pallet Rectifier?

The benefits of working as a Pallet Rectifier can include a steady income, opportunities for advancement, and the chance to work with a variety of people.

What are the challenges of working as a Pallet Rectifier?

The challenges of working as a Pallet Rectifier can include working in a fast-paced environment, lifting heavy objects, and working in extreme temperatures and noise levels.