Are you a seasoned Para Machine Operator seeking a new career path? Discover our professionally built Para Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

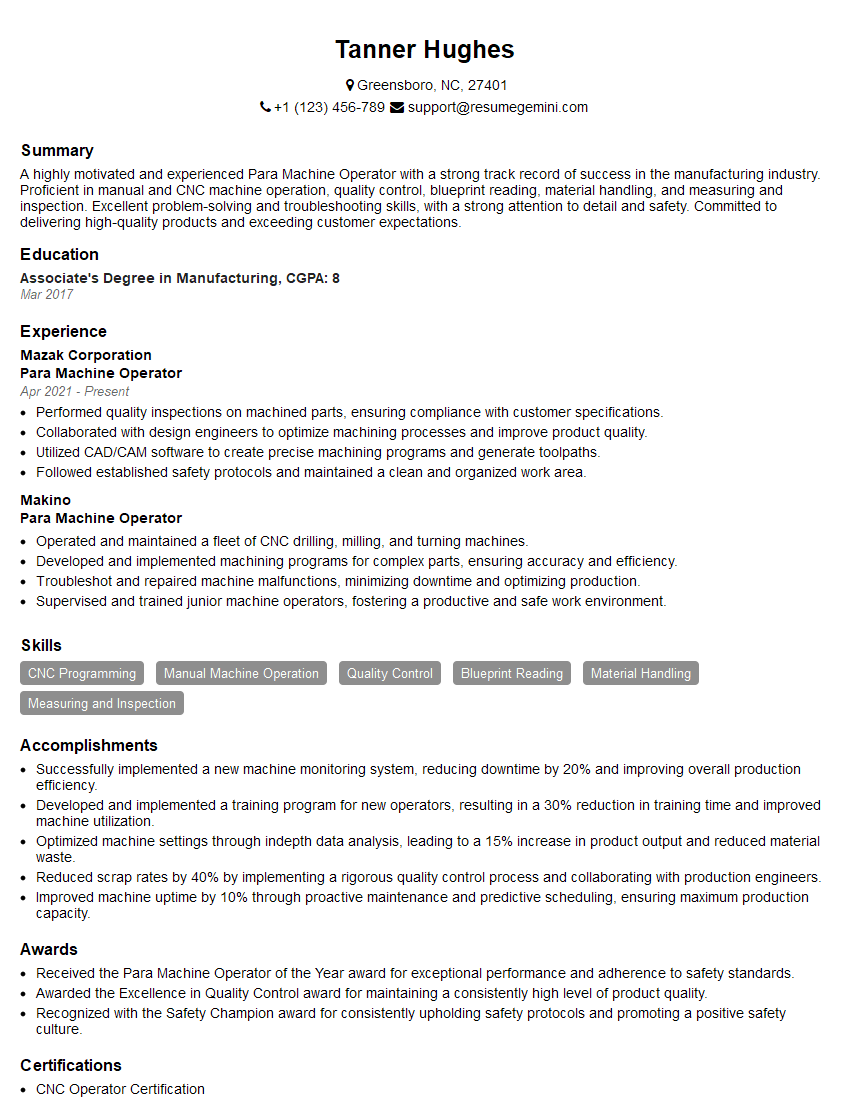

Tanner Hughes

Para Machine Operator

Summary

A highly motivated and experienced Para Machine Operator with a strong track record of success in the manufacturing industry. Proficient in manual and CNC machine operation, quality control, blueprint reading, material handling, and measuring and inspection. Excellent problem-solving and troubleshooting skills, with a strong attention to detail and safety. Committed to delivering high-quality products and exceeding customer expectations.

Education

Associate’s Degree in Manufacturing

March 2017

Skills

- CNC Programming

- Manual Machine Operation

- Quality Control

- Blueprint Reading

- Material Handling

- Measuring and Inspection

Work Experience

Para Machine Operator

- Performed quality inspections on machined parts, ensuring compliance with customer specifications.

- Collaborated with design engineers to optimize machining processes and improve product quality.

- Utilized CAD/CAM software to create precise machining programs and generate toolpaths.

- Followed established safety protocols and maintained a clean and organized work area.

Para Machine Operator

- Operated and maintained a fleet of CNC drilling, milling, and turning machines.

- Developed and implemented machining programs for complex parts, ensuring accuracy and efficiency.

- Troubleshot and repaired machine malfunctions, minimizing downtime and optimizing production.

- Supervised and trained junior machine operators, fostering a productive and safe work environment.

Accomplishments

- Successfully implemented a new machine monitoring system, reducing downtime by 20% and improving overall production efficiency.

- Developed and implemented a training program for new operators, resulting in a 30% reduction in training time and improved machine utilization.

- Optimized machine settings through indepth data analysis, leading to a 15% increase in product output and reduced material waste.

- Reduced scrap rates by 40% by implementing a rigorous quality control process and collaborating with production engineers.

- Improved machine uptime by 10% through proactive maintenance and predictive scheduling, ensuring maximum production capacity.

Awards

- Received the Para Machine Operator of the Year award for exceptional performance and adherence to safety standards.

- Awarded the Excellence in Quality Control award for maintaining a consistently high level of product quality.

- Recognized with the Safety Champion award for consistently upholding safety protocols and promoting a positive safety culture.

Certificates

- CNC Operator Certification

- Manual Machinist Certification

- Quality Control Certification

- Blueprint Reading Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Para Machine Operator

- Highlight your relevant skills and experience by quantifying your accomplishments and providing specific examples.

- Tailor your resume to each job you apply for, emphasizing the skills and experience that are most relevant to the position.

- Proofread your resume carefully before submitting it to ensure there are no errors.

- Consider getting your resume reviewed by a career counselor or professional resume writer.

Essential Experience Highlights for a Strong Para Machine Operator Resume

- Operate and control various para machines, including lathes, mills, and grinders

- Interpret blueprints and technical drawings to determine work specifications

- Set up and adjust machines according to specifications

- Perform quality control inspections on finished products to ensure they meet standards

- Troubleshoot and resolve machine malfunctions to minimize downtime

- Maintain a clean and organized work area, adhering to safety regulations

Frequently Asked Questions (FAQ’s) For Para Machine Operator

What is a Para Machine Operator?

A Para Machine Operator is responsible for operating and maintaining a variety of machines, including lathes, mills, and grinders, to produce high-quality parts and products.

What skills are required to be a Para Machine Operator?

To be a successful Para Machine Operator, you need to have strong technical skills, including CNC programming, manual machine operation, quality control, blueprint reading, material handling, and measuring and inspection.

What is the work environment for a Para Machine Operator?

Para Machine Operators typically work in manufacturing facilities, where they operate machines in a variety of settings, including workshops, assembly lines, and production plants.

Is there a demand for Para Machine Operators?

Yes, there is a high demand for Para Machine Operators due to the growing manufacturing industry. Many companies are looking for skilled operators to help them meet production demands.

What is the salary range for a Para Machine Operator?

The salary range for a Para Machine Operator can vary depending on experience, skills, and location. According to Indeed, the average salary for a Para Machine Operator in the United States is around $25 per hour.

What are the career prospects for a Para Machine Operator?

Para Machine Operators can advance their careers by gaining additional skills and experience. They can become CNC programmers, quality control inspectors, or production supervisors.

What are the challenges of being a Para Machine Operator?

Some challenges that Para Machine Operators may face include working in a fast-paced environment, meeting production deadlines, and working with hazardous materials.

What are the rewards of being a Para Machine Operator?

Para Machine Operators can experience job satisfaction by producing high-quality parts and products, contributing to the success of the company, and earning a competitive salary.