Are you a seasoned Pickling Solution Maker seeking a new career path? Discover our professionally built Pickling Solution Maker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

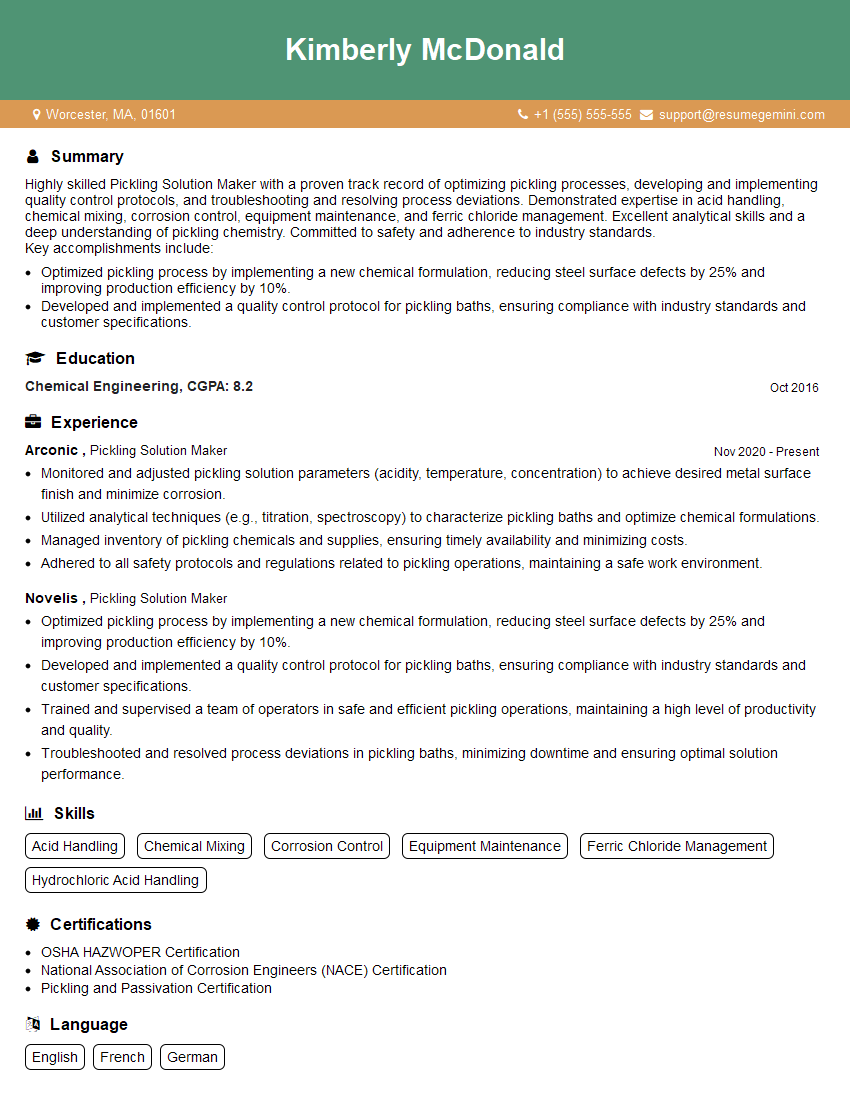

Kimberly McDonald

Pickling Solution Maker

Summary

Highly skilled Pickling Solution Maker with a proven track record of optimizing pickling processes, developing and implementing quality control protocols, and troubleshooting and resolving process deviations. Demonstrated expertise in acid handling, chemical mixing, corrosion control, equipment maintenance, and ferric chloride management. Excellent analytical skills and a deep understanding of pickling chemistry. Committed to safety and adherence to industry standards.

Key accomplishments include:

- Optimized pickling process by implementing a new chemical formulation, reducing steel surface defects by 25% and improving production efficiency by 10%.

- Developed and implemented a quality control protocol for pickling baths, ensuring compliance with industry standards and customer specifications.

Education

Chemical Engineering

October 2016

Skills

- Acid Handling

- Chemical Mixing

- Corrosion Control

- Equipment Maintenance

- Ferric Chloride Management

- Hydrochloric Acid Handling

Work Experience

Pickling Solution Maker

- Monitored and adjusted pickling solution parameters (acidity, temperature, concentration) to achieve desired metal surface finish and minimize corrosion.

- Utilized analytical techniques (e.g., titration, spectroscopy) to characterize pickling baths and optimize chemical formulations.

- Managed inventory of pickling chemicals and supplies, ensuring timely availability and minimizing costs.

- Adhered to all safety protocols and regulations related to pickling operations, maintaining a safe work environment.

Pickling Solution Maker

- Optimized pickling process by implementing a new chemical formulation, reducing steel surface defects by 25% and improving production efficiency by 10%.

- Developed and implemented a quality control protocol for pickling baths, ensuring compliance with industry standards and customer specifications.

- Trained and supervised a team of operators in safe and efficient pickling operations, maintaining a high level of productivity and quality.

- Troubleshooted and resolved process deviations in pickling baths, minimizing downtime and ensuring optimal solution performance.

Certificates

- OSHA HAZWOPER Certification

- National Association of Corrosion Engineers (NACE) Certification

- Pickling and Passivation Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Pickling Solution Maker

- Highlight your technical skills: Emphasize your expertise in acid handling, chemical mixing, corrosion control, and analytical techniques.

- Quantify your accomplishments: Use specific metrics to demonstrate the impact of your work, such as reducing defects or improving efficiency.

- Showcase your safety??: Highlight your commitment to safety and adherence to industry regulations.

- Tailor your resume to the job description: Carefully review the job description and tailor your resume to match the specific requirements and keywords.

Essential Experience Highlights for a Strong Pickling Solution Maker Resume

- Optimize pickling processes to improve surface finish and minimize defects.

- Develop and implement quality control protocols for pickling baths to ensure compliance with industry standards.

- Train and supervise a team of operators in safe and efficient pickling operations.

- Troubleshoot and resolve process deviations in pickling baths to minimize downtime.

- Monitor and adjust pickling solution parameters (acidity, temperature, concentration) to achieve desired metal surface finish and minimize corrosion.

- Manage inventory of pickling chemicals and supplies to ensure timely availability and minimize costs.

Frequently Asked Questions (FAQ’s) For Pickling Solution Maker

What is the primary role of a Pickling Solution Maker?

The primary role of a Pickling Solution Maker is to optimize and maintain pickling solutions used in metal surface treatment processes.

What are the key skills required for a Pickling Solution Maker?

Key skills include acid handling, chemical mixing, corrosion control, equipment maintenance, ferric chloride management, and analytical techniques.

What industries employ Pickling Solution Makers?

Pickling Solution Makers are employed in various industries, including metal fabrication, automotive, and aerospace.

What is the job outlook for Pickling Solution Makers?

The job outlook is expected to be positive due to the increasing demand for metal surface treatment processes in various industries.

What are the career advancement opportunities for Pickling Solution Makers?

Career advancement opportunities can include positions such as Process Engineer, Quality Control Manager, or Production Supervisor.

What are the safety precautions that Pickling Solution Makers must follow?

Pickling Solution Makers must follow strict safety protocols to handle acids and chemicals safely, including wearing appropriate protective gear and adhering to ventilation and disposal guidelines.

What are the environmental considerations for Pickling Solution Makers?

Pickling Solution Makers must be aware of the environmental impact of pickling chemicals and implement proper waste management practices to minimize pollution.