Are you a seasoned Piercing Machine Operator seeking a new career path? Discover our professionally built Piercing Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

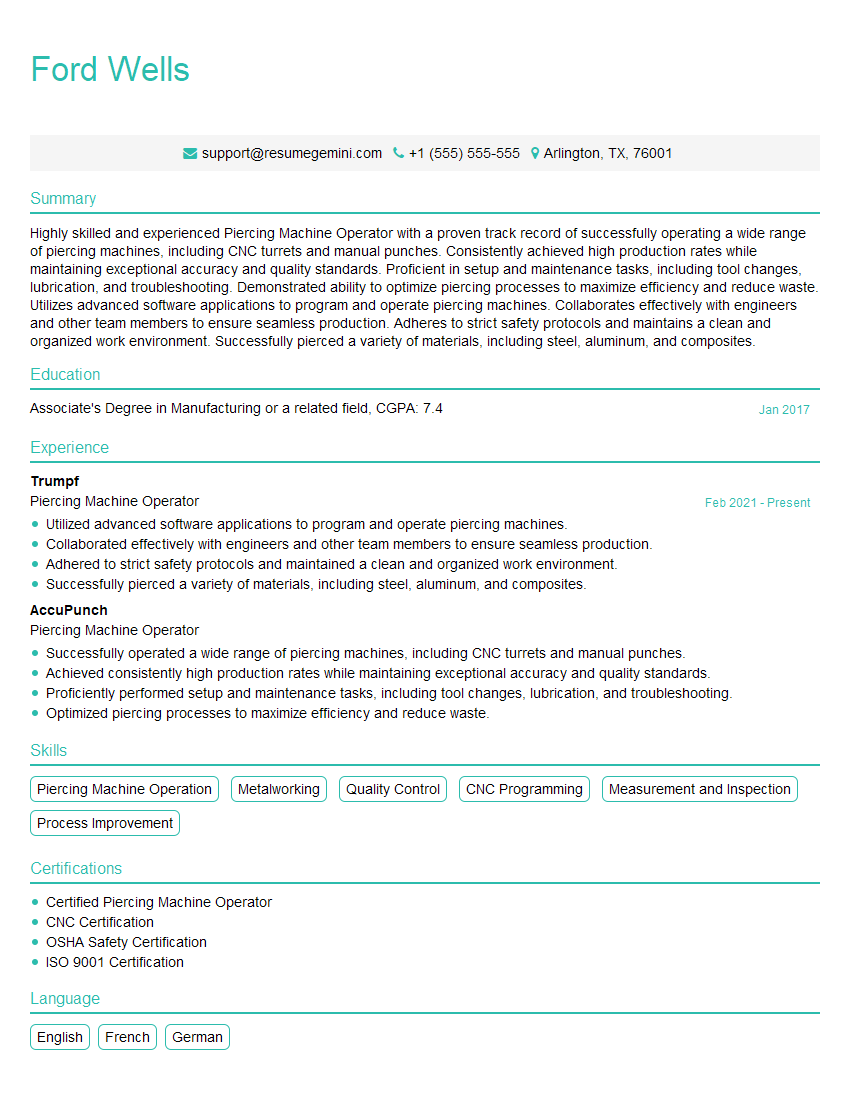

Ford Wells

Piercing Machine Operator

Summary

Highly skilled and experienced Piercing Machine Operator with a proven track record of successfully operating a wide range of piercing machines, including CNC turrets and manual punches. Consistently achieved high production rates while maintaining exceptional accuracy and quality standards. Proficient in setup and maintenance tasks, including tool changes, lubrication, and troubleshooting. Demonstrated ability to optimize piercing processes to maximize efficiency and reduce waste. Utilizes advanced software applications to program and operate piercing machines. Collaborates effectively with engineers and other team members to ensure seamless production. Adheres to strict safety protocols and maintains a clean and organized work environment. Successfully pierced a variety of materials, including steel, aluminum, and composites.

Education

Associate’s Degree in Manufacturing or a related field

January 2017

Skills

- Piercing Machine Operation

- Metalworking

- Quality Control

- CNC Programming

- Measurement and Inspection

- Process Improvement

Work Experience

Piercing Machine Operator

- Utilized advanced software applications to program and operate piercing machines.

- Collaborated effectively with engineers and other team members to ensure seamless production.

- Adhered to strict safety protocols and maintained a clean and organized work environment.

- Successfully pierced a variety of materials, including steel, aluminum, and composites.

Piercing Machine Operator

- Successfully operated a wide range of piercing machines, including CNC turrets and manual punches.

- Achieved consistently high production rates while maintaining exceptional accuracy and quality standards.

- Proficiently performed setup and maintenance tasks, including tool changes, lubrication, and troubleshooting.

- Optimized piercing processes to maximize efficiency and reduce waste.

Certificates

- Certified Piercing Machine Operator

- CNC Certification

- OSHA Safety Certification

- ISO 9001 Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Piercing Machine Operator

- Highlight your experience with different types of piercing machines and your ability to achieve high production rates.

- Emphasize your skills in setup and maintenance, as well as your ability to troubleshoot and resolve problems.

- Showcase your knowledge of advanced software applications used in piercing machines.

- Demonstrate your commitment to safety and your ability to work effectively in a team environment.

- Include specific examples of how you have optimized piercing processes and reduced waste.

Essential Experience Highlights for a Strong Piercing Machine Operator Resume

- Operate a variety of piercing machines, including CNC turrets and manual punches

- Achieve consistently high production rates while maintaining exceptional accuracy and quality standards

- Perform setup and maintenance tasks, including tool changes, lubrication, and troubleshooting

- Optimize piercing processes to maximize efficiency and reduce waste

- Utilize advanced software applications to program and operate piercing machines

- Collaborate effectively with engineers and other team members to ensure seamless production

- Adhere to strict safety protocols and maintain a clean and organized work environment

Frequently Asked Questions (FAQ’s) For Piercing Machine Operator

What are the key skills required to be a successful Piercing Machine Operator?

The key skills required to be a successful Piercing Machine Operator include a strong understanding of piercing machine operation, metalworking, quality control, CNC programming, measurement and inspection, and process improvement.

What are the career prospects for Piercing Machine Operators?

Piercing Machine Operators can advance to supervisory roles, such as Piercing Machine Supervisor or Production Manager. They may also specialize in a particular type of piercing machine or material.

What are the working conditions for Piercing Machine Operators?

Piercing Machine Operators typically work in a manufacturing environment. They may be exposed to noise, dust, and fumes. They must be able to stand for long periods of time and lift heavy objects.

What is the average salary for Piercing Machine Operators?

The average salary for Piercing Machine Operators varies depending on experience, location, and company size. According to Indeed, the average salary for Piercing Machine Operators in the United States is $20.50 per hour.

What are the educational requirements for Piercing Machine Operators?

Most Piercing Machine Operators have a high school diploma or equivalent. Some employers may require a post-secondary degree in a related field, such as manufacturing or engineering.