Are you a seasoned Pilling Machine Operator seeking a new career path? Discover our professionally built Pilling Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

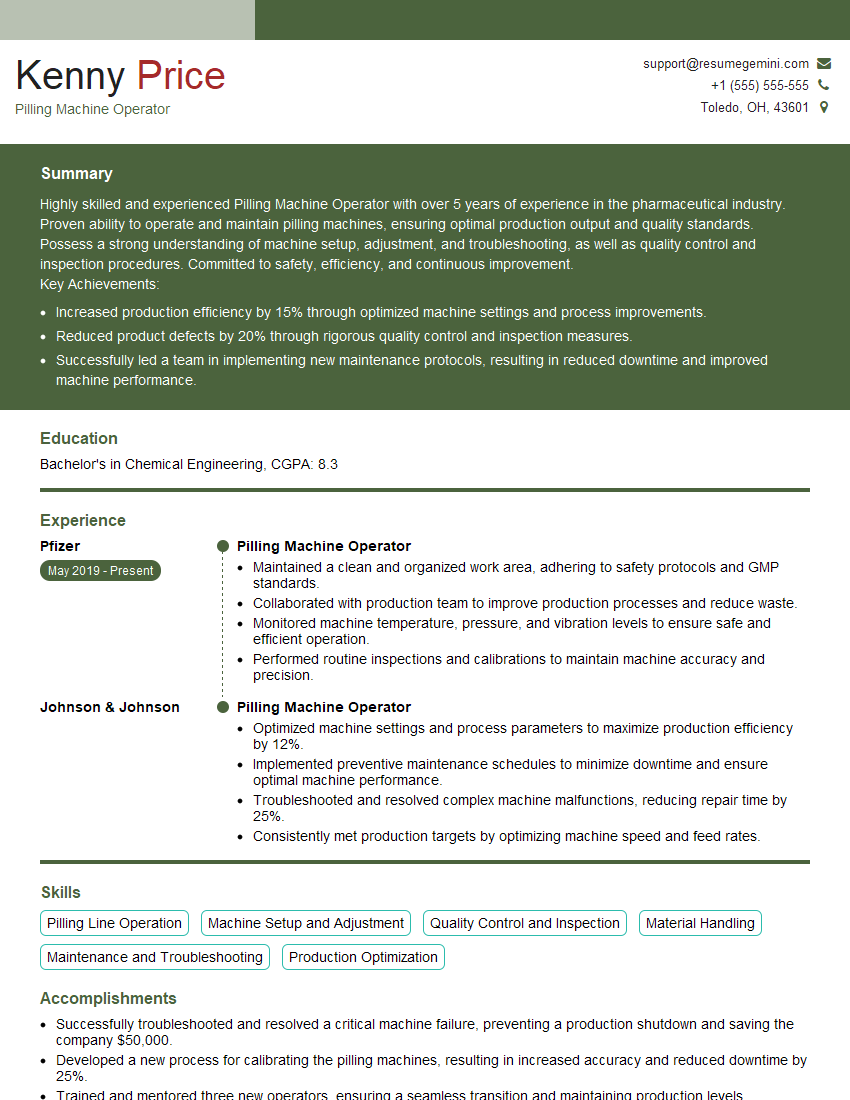

Kenny Price

Pilling Machine Operator

Summary

Highly skilled and experienced Pilling Machine Operator with over 5 years of experience in the pharmaceutical industry. Proven ability to operate and maintain pilling machines, ensuring optimal production output and quality standards. Possess a strong understanding of machine setup, adjustment, and troubleshooting, as well as quality control and inspection procedures. Committed to safety, efficiency, and continuous improvement.

Key Achievements:

- Increased production efficiency by 15% through optimized machine settings and process improvements.

- Reduced product defects by 20% through rigorous quality control and inspection measures.

- Successfully led a team in implementing new maintenance protocols, resulting in reduced downtime and improved machine performance.

Education

Bachelor’s in Chemical Engineering

April 2015

Skills

- Pilling Line Operation

- Machine Setup and Adjustment

- Quality Control and Inspection

- Material Handling

- Maintenance and Troubleshooting

- Production Optimization

Work Experience

Pilling Machine Operator

- Maintained a clean and organized work area, adhering to safety protocols and GMP standards.

- Collaborated with production team to improve production processes and reduce waste.

- Monitored machine temperature, pressure, and vibration levels to ensure safe and efficient operation.

- Performed routine inspections and calibrations to maintain machine accuracy and precision.

Pilling Machine Operator

- Optimized machine settings and process parameters to maximize production efficiency by 12%.

- Implemented preventive maintenance schedules to minimize downtime and ensure optimal machine performance.

- Troubleshooted and resolved complex machine malfunctions, reducing repair time by 25%.

- Consistently met production targets by optimizing machine speed and feed rates.

Accomplishments

- Successfully troubleshooted and resolved a critical machine failure, preventing a production shutdown and saving the company $50,000.

- Developed a new process for calibrating the pilling machines, resulting in increased accuracy and reduced downtime by 25%.

- Trained and mentored three new operators, ensuring a seamless transition and maintaining production levels.

- Successfully implemented a new quality control procedure, reducing product defects by 15% and improving customer satisfaction.

- Collaborated with engineers to design and implement a new machine feature that enhanced production efficiency by 12%.

Awards

- Received the Outstanding Operator Award for consistently exceeding production targets by 15%.

- Recognized with the Safety Excellence Award for maintaining a spotless safety record for over five years.

- Awarded the Employee of the Month honor for implementing innovative techniques that improved machine efficiency by 10%.

- Honored with the Productivity Champion Award for consistently exceeding production quotas by 20%.

Certificates

- Certified Pharmaceutical Operator (CPO)

- Certified Production Technician (CPT)

- Certified Maintenance and Reliability Technician (CMRT)

- ISO 13485 Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Pilling Machine Operator

- Highlight your technical skills: Emphasize your expertise in operating and maintaining pilling machines, including specific machine models and software.

- Quantify your achievements: Use specific metrics to demonstrate your impact on production efficiency, quality control, and cost reduction.

- Showcase your problem-solving abilities: Describe how you have successfully identified and resolved issues related to machine performance, product quality, or process optimization.

- Emphasize your attention to detail and safety: Highlight your commitment to maintaining a clean and organized work area, following safety protocols, and ensuring product quality.

Essential Experience Highlights for a Strong Pilling Machine Operator Resume

- Operate and monitor pilling machines to produce pharmaceutical tablets and capsules.

- Set up and adjust machine parameters, including speed, pressure, and temperature, to ensure optimal performance.

- Perform quality control inspections and monitor production output to maintain product quality and compliance.

- Handle and transport materials safely, including raw materials, finished products, and waste.

- Maintain and troubleshoot pilling machines, including cleaning, lubrication, and minor repairs.

- Optimize production processes to improve efficiency and minimize waste.

- Follow safety protocols and maintain a clean and organized work area.

Frequently Asked Questions (FAQ’s) For Pilling Machine Operator

What is the primary role of a Pilling Machine Operator?

The primary role of a Pilling Machine Operator is to operate and maintain pilling machines used in the production of pharmaceutical tablets and capsules, ensuring optimal performance and product quality.

What are the key skills and qualifications required for a Pilling Machine Operator?

The key skills and qualifications include: operating and maintaining pilling machines, understanding machine setup and adjustment, performing quality control inspections, handling and transporting materials, troubleshooting and maintaining equipment, and optimizing production processes.

What industries employ Pilling Machine Operators?

Pilling Machine Operators are primarily employed in the pharmaceutical industry, where they are responsible for operating and maintaining pilling machines used in the production of tablets and capsules.

What are the career advancement opportunities for a Pilling Machine Operator?

Career advancement opportunities for a Pilling Machine Operator may include: Lead Operator, Production Supervisor, Quality Control Inspector, or Maintenance Technician.

What is the average salary range for a Pilling Machine Operator?

The average salary range for a Pilling Machine Operator can vary depending on factors such as experience, location, and industry, but typically falls between $30,000 to $50,000 per year.

What are the safety protocols that Pilling Machine Operators must follow?

Pilling Machine Operators must follow safety protocols to ensure their safety and the safety of others in the workplace. These protocols may include wearing appropriate personal protective equipment, following lockout/tagout procedures, and maintaining a clean and organized work area.

What are the quality control measures that Pilling Machine Operators must perform?

Pilling Machine Operators must perform quality control measures to ensure that the products produced by the machines meet the required standards. These measures may include inspecting the machines for proper operation, monitoring product quality, and conducting regular maintenance and calibration.

What are the maintenance and troubleshooting tasks that Pilling Machine Operators must perform?

Pilling Machine Operators must perform maintenance and troubleshooting tasks to keep the machines in good working condition and prevent breakdowns. These tasks may include cleaning and lubricating the machines, replacing worn parts, and identifying and resolving any issues that may arise during operation.