Are you a seasoned Pipe Coremaker seeking a new career path? Discover our professionally built Pipe Coremaker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

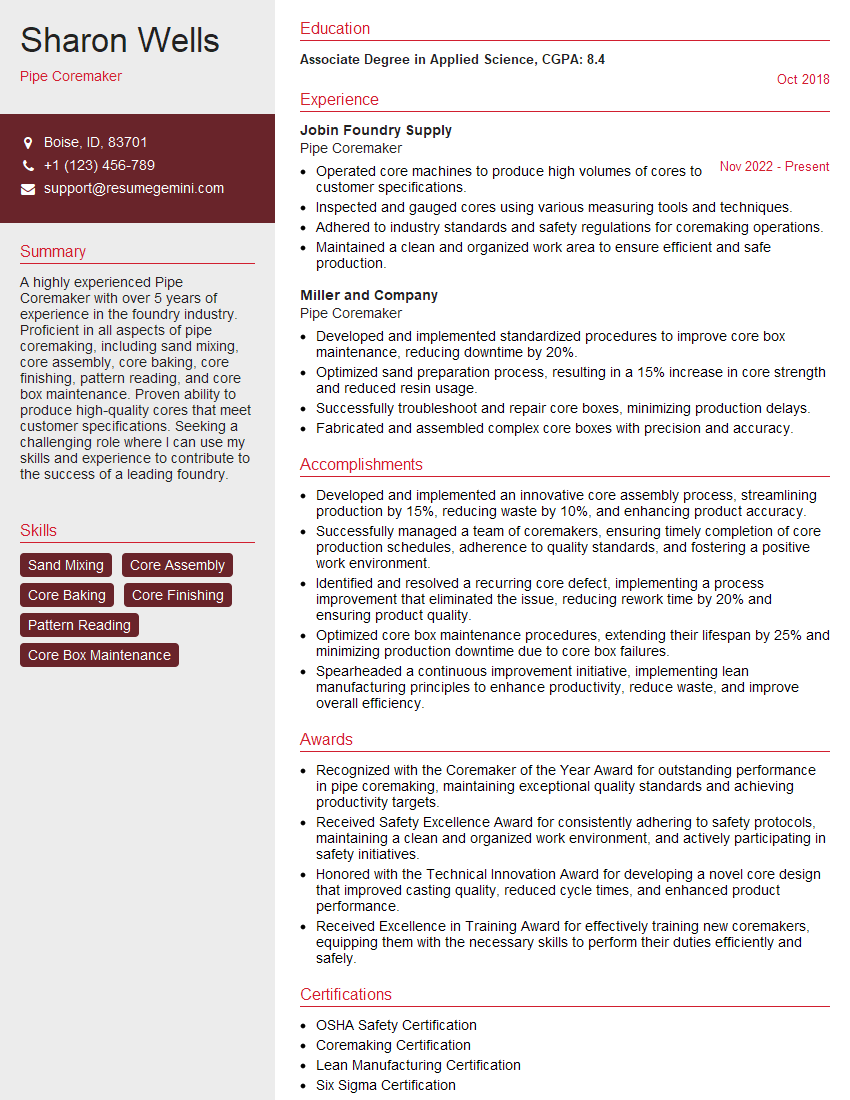

Sharon Wells

Pipe Coremaker

Summary

A highly experienced Pipe Coremaker with over 5 years of experience in the foundry industry. Proficient in all aspects of pipe coremaking, including sand mixing, core assembly, core baking, core finishing, pattern reading, and core box maintenance. Proven ability to produce high-quality cores that meet customer specifications. Seeking a challenging role where I can use my skills and experience to contribute to the success of a leading foundry.

Education

Associate Degree in Applied Science

October 2018

Skills

- Sand Mixing

- Core Assembly

- Core Baking

- Core Finishing

- Pattern Reading

- Core Box Maintenance

Work Experience

Pipe Coremaker

- Operated core machines to produce high volumes of cores to customer specifications.

- Inspected and gauged cores using various measuring tools and techniques.

- Adhered to industry standards and safety regulations for coremaking operations.

- Maintained a clean and organized work area to ensure efficient and safe production.

Pipe Coremaker

- Developed and implemented standardized procedures to improve core box maintenance, reducing downtime by 20%.

- Optimized sand preparation process, resulting in a 15% increase in core strength and reduced resin usage.

- Successfully troubleshoot and repair core boxes, minimizing production delays.

- Fabricated and assembled complex core boxes with precision and accuracy.

Accomplishments

- Developed and implemented an innovative core assembly process, streamlining production by 15%, reducing waste by 10%, and enhancing product accuracy.

- Successfully managed a team of coremakers, ensuring timely completion of core production schedules, adherence to quality standards, and fostering a positive work environment.

- Identified and resolved a recurring core defect, implementing a process improvement that eliminated the issue, reducing rework time by 20% and ensuring product quality.

- Optimized core box maintenance procedures, extending their lifespan by 25% and minimizing production downtime due to core box failures.

- Spearheaded a continuous improvement initiative, implementing lean manufacturing principles to enhance productivity, reduce waste, and improve overall efficiency.

Awards

- Recognized with the Coremaker of the Year Award for outstanding performance in pipe coremaking, maintaining exceptional quality standards and achieving productivity targets.

- Received Safety Excellence Award for consistently adhering to safety protocols, maintaining a clean and organized work environment, and actively participating in safety initiatives.

- Honored with the Technical Innovation Award for developing a novel core design that improved casting quality, reduced cycle times, and enhanced product performance.

- Received Excellence in Training Award for effectively training new coremakers, equipping them with the necessary skills to perform their duties efficiently and safely.

Certificates

- OSHA Safety Certification

- Coremaking Certification

- Lean Manufacturing Certification

- Six Sigma Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Pipe Coremaker

- Highlight your experience and skills related to pipe coremaking specifically.

- Provide quantifiable results to demonstrate your impact on productivity or quality.

- Showcase your knowledge of coremaking techniques and industry best practices.

- Include any certifications or training programs that attest to your competence.

- Review sample Pipe Coremaker resumes for inspiration and to see what hiring managers are looking for.

Essential Experience Highlights for a Strong Pipe Coremaker Resume

- Setup and preparation of core boxes, tools, and equipment.

- Mixing and preparing sand using various binders and additives.

- Assembling and finishing cores according to specifications.

- Baking and curing cores in ovens and autoclaves.

- Inspecting and testing cores to ensure quality standards.

- Identifying and troubleshooting core defects.

- Maintaining and repairing core boxes and related equipment.

Frequently Asked Questions (FAQ’s) For Pipe Coremaker

What are the key skills required to be a successful Pipe Coremaker?

Key skills for a Pipe Coremaker include sand mixing, core assembly, core baking, core finishing, pattern reading, core box maintenance, and a strong understanding of foundry processes.

What industries hire Pipe Coremakers?

Pipe Coremakers are employed in various industries, including foundries, metalworking, and automotive.

What is the average salary for a Pipe Coremaker?

The average salary for a Pipe Coremaker in the United States is around $35,000 per year.

What are the career advancement opportunities for a Pipe Coremaker?

Pipe Coremakers can advance their careers by becoming supervisors, quality control inspectors, or production managers.

What is the job outlook for Pipe Coremakers?

The job outlook for Pipe Coremakers is expected to be stable in the coming years due to the ongoing demand for skilled foundry workers.

What type of work environment can Pipe Coremakers expect?

Pipe Coremakers typically work in foundries, which can be noisy and have fumes and dust.