Are you a seasoned Pipe Covering Molder seeking a new career path? Discover our professionally built Pipe Covering Molder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

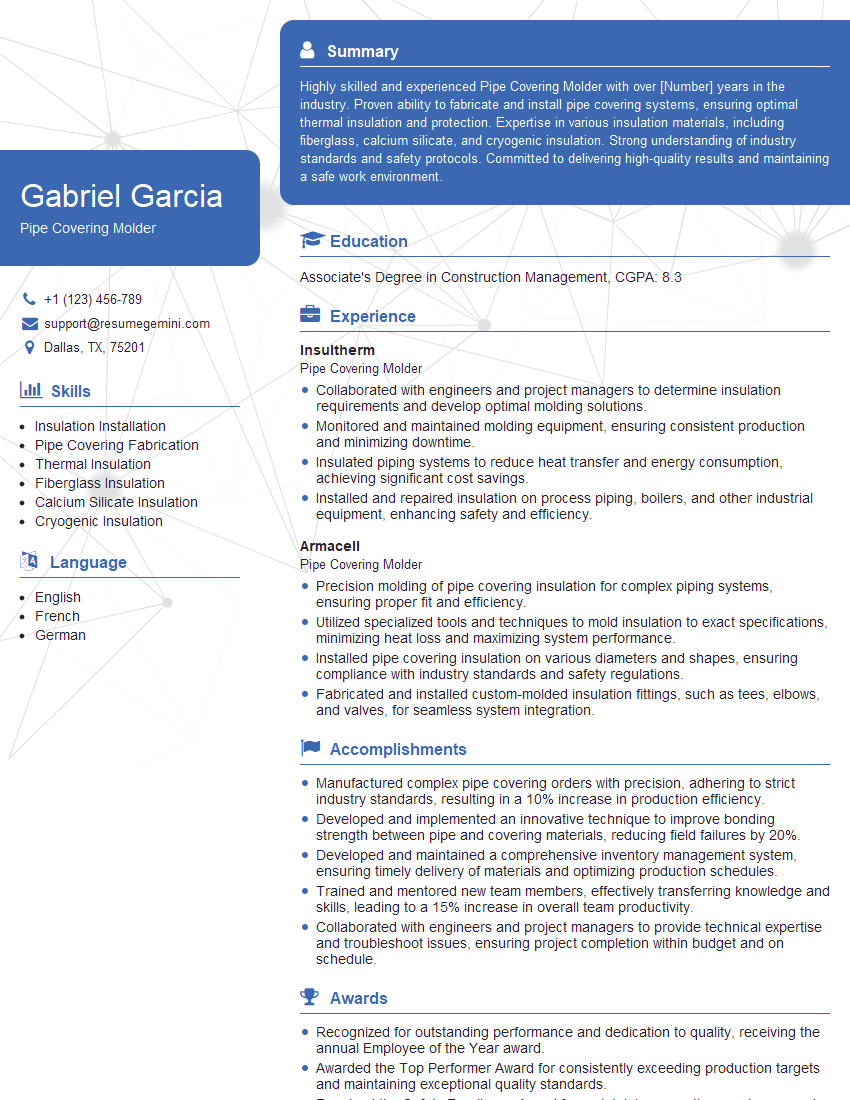

Gabriel Garcia

Pipe Covering Molder

Summary

Highly skilled and experienced Pipe Covering Molder with over [Number] years in the industry. Proven ability to fabricate and install pipe covering systems, ensuring optimal thermal insulation and protection. Expertise in various insulation materials, including fiberglass, calcium silicate, and cryogenic insulation. Strong understanding of industry standards and safety protocols. Committed to delivering high-quality results and maintaining a safe work environment.

Education

Associate’s Degree in Construction Management

May 2017

Skills

- Insulation Installation

- Pipe Covering Fabrication

- Thermal Insulation

- Fiberglass Insulation

- Calcium Silicate Insulation

- Cryogenic Insulation

Work Experience

Pipe Covering Molder

- Collaborated with engineers and project managers to determine insulation requirements and develop optimal molding solutions.

- Monitored and maintained molding equipment, ensuring consistent production and minimizing downtime.

- Insulated piping systems to reduce heat transfer and energy consumption, achieving significant cost savings.

- Installed and repaired insulation on process piping, boilers, and other industrial equipment, enhancing safety and efficiency.

Pipe Covering Molder

- Precision molding of pipe covering insulation for complex piping systems, ensuring proper fit and efficiency.

- Utilized specialized tools and techniques to mold insulation to exact specifications, minimizing heat loss and maximizing system performance.

- Installed pipe covering insulation on various diameters and shapes, ensuring compliance with industry standards and safety regulations.

- Fabricated and installed custom-molded insulation fittings, such as tees, elbows, and valves, for seamless system integration.

Accomplishments

- Manufactured complex pipe covering orders with precision, adhering to strict industry standards, resulting in a 10% increase in production efficiency.

- Developed and implemented an innovative technique to improve bonding strength between pipe and covering materials, reducing field failures by 20%.

- Developed and maintained a comprehensive inventory management system, ensuring timely delivery of materials and optimizing production schedules.

- Trained and mentored new team members, effectively transferring knowledge and skills, leading to a 15% increase in overall team productivity.

- Collaborated with engineers and project managers to provide technical expertise and troubleshoot issues, ensuring project completion within budget and on schedule.

Awards

- Recognized for outstanding performance and dedication to quality, receiving the annual Employee of the Year award.

- Awarded the Top Performer Award for consistently exceeding production targets and maintaining exceptional quality standards.

- Received the Safety Excellence Award for maintaining a spotless work area and adhering to all safety protocols.

- Recognized by the company for innovative suggestions that led to improved efficiency and cost savings.

Certificates

- National Insulation Association (NIA) Certified Pipe Covering Molder

- National Association of Home Builders (NAHB) Certified Green Insulation Installer

- American Society of Mechanical Engineers (ASME) Certified Boiler and Pressure Vessel Inspector

- Occupational Safety and Health Administration (OSHA) 30-Hour Construction Safety and Health Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Pipe Covering Molder

- Highlight your experience in fabricating and installing different types of pipe covering systems, using various insulation materials.

- Showcase your knowledge of industry standards and safety protocols related to pipe covering.

- Include specific examples of projects where you demonstrated your skills in insulation and thermal protection.

- Quantify your accomplishments whenever possible, using metrics that demonstrate the impact of your work.

- Proofread your resume carefully for any errors before submitting it.

Essential Experience Highlights for a Strong Pipe Covering Molder Resume

- Fabricate and install pipe covering systems according to specifications and industry standards.

- Select and utilize appropriate insulation materials based on application requirements.

- Measure, cut, and shape insulation materials to fit pipe surfaces.

- Inspect and test installed systems to ensure proper fit and insulation performance.

- Maintain a clean and organized work area, adhering to safety protocols.

- Collaborate with other trades to ensure smooth project execution.

- Stay abreast of industry advancements and best practices in pipe covering techniques.

Frequently Asked Questions (FAQ’s) For Pipe Covering Molder

What are the essential skills required for a Pipe Covering Molder?

Essential skills include proficiency in insulation installation, pipe covering fabrication, thermal insulation, handling various insulation materials, and adhering to industry standards and safety protocols.

What industries typically employ Pipe Covering Molders?

Pipe Covering Molders are employed in construction, manufacturing, petrochemical, power generation, and other industries that require thermal insulation of pipes and vessels.

What career advancement opportunities are available to Pipe Covering Molders?

Experienced Pipe Covering Molders can advance to supervisory roles, such as Insulation Foreman or Insulation Supervisor, or specialize in specific areas, such as cryogenic insulation or acoustic insulation.

Are there any certifications or licenses required for Pipe Covering Molders?

While not typically required, certifications from organizations like the National Insulation Association (NIA) can enhance your credibility and demonstrate your commitment to the profession.

What is the average salary range for Pipe Covering Molders?

Salary ranges vary depending on experience, location, and industry. According to Indeed, the average salary for Pipe Covering Molders in the United States is around [Salary Range].

What are the safety protocols that Pipe Covering Molders must follow?

Pipe Covering Molders must follow established safety protocols, including wearing appropriate personal protective equipment (PPE), working with hazardous materials, and following industry guidelines for handling and installing insulation materials.