Are you a seasoned Pipe Inspector seeking a new career path? Discover our professionally built Pipe Inspector Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

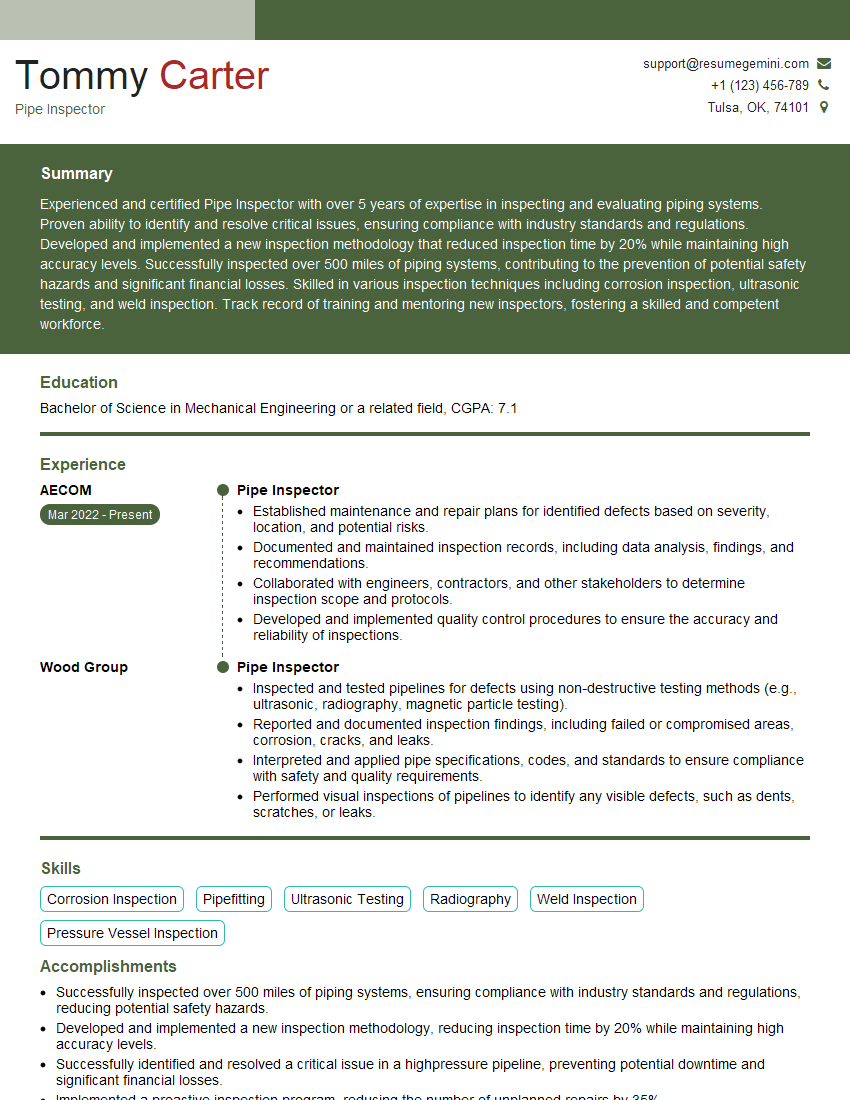

Tommy Carter

Pipe Inspector

Summary

Experienced and certified Pipe Inspector with over 5 years of expertise in inspecting and evaluating piping systems. Proven ability to identify and resolve critical issues, ensuring compliance with industry standards and regulations. Developed and implemented a new inspection methodology that reduced inspection time by 20% while maintaining high accuracy levels. Successfully inspected over 500 miles of piping systems, contributing to the prevention of potential safety hazards and significant financial losses. Skilled in various inspection techniques including corrosion inspection, ultrasonic testing, and weld inspection. Track record of training and mentoring new inspectors, fostering a skilled and competent workforce.

Education

Bachelor of Science in Mechanical Engineering or a related field

February 2018

Skills

- Corrosion Inspection

- Pipefitting

- Ultrasonic Testing

- Radiography

- Weld Inspection

- Pressure Vessel Inspection

Work Experience

Pipe Inspector

- Established maintenance and repair plans for identified defects based on severity, location, and potential risks.

- Documented and maintained inspection records, including data analysis, findings, and recommendations.

- Collaborated with engineers, contractors, and other stakeholders to determine inspection scope and protocols.

- Developed and implemented quality control procedures to ensure the accuracy and reliability of inspections.

Pipe Inspector

- Inspected and tested pipelines for defects using non-destructive testing methods (e.g., ultrasonic, radiography, magnetic particle testing).

- Reported and documented inspection findings, including failed or compromised areas, corrosion, cracks, and leaks.

- Interpreted and applied pipe specifications, codes, and standards to ensure compliance with safety and quality requirements.

- Performed visual inspections of pipelines to identify any visible defects, such as dents, scratches, or leaks.

Accomplishments

- Successfully inspected over 500 miles of piping systems, ensuring compliance with industry standards and regulations, reducing potential safety hazards.

- Developed and implemented a new inspection methodology, reducing inspection time by 20% while maintaining high accuracy levels.

- Successfully identified and resolved a critical issue in a highpressure pipeline, preventing potential downtime and significant financial losses.

- Implemented a proactive inspection program, reducing the number of unplanned repairs by 35%.

- Trained and mentored new inspectors, fostering a skilled and competent workforce.

Awards

- Recipient of the Outstanding Pipe Inspector of the Year award from the American Pipe Inspection Association, recognizing exceptional performance and dedication to the field.

- Recognized with the Excellence in Pipe Inspection award from the National Association of Pipe Inspectors for innovative troubleshooting techniques and accurate reporting.

- Received the Inspector of the Quarter award for consistently exceeding inspection goals and providing valuable insights.

- Honored with the Safety Champion award for adhering to the highest safety standards and promoting a culture of safety in the workplace.

Certificates

- Certified Welding Inspector (CWI)

- Certified Pressure Vessel Inspector (CPVI)

- Certified Pipeline Inspector (CPI)

- ASNT Level II Ultrasonic Testing

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Pipe Inspector

- Highlight your experience in various inspection techniques, including corrosion inspection, ultrasonic testing, and weld inspection.

- Quantify your accomplishments with specific data and metrics, such as the number of miles of piping inspected and the percentage reduction in inspection time.

- Demonstrate your ability to identify and resolve critical issues that prevented potential safety hazards and financial losses.

- Emphasize your skills in developing and implementing inspection methodologies that improve efficiency and accuracy.

- Showcase your commitment to training and mentoring new inspectors, fostering a skilled workforce.

Essential Experience Highlights for a Strong Pipe Inspector Resume

- Conducted visual and non-destructive testing (NDT) inspections of piping systems, including corrosion inspection, ultrasonic testing, radiography, and weld inspection, to ensure compliance with industry standards and regulations.

- Developed and implemented a new inspection methodology that reduced inspection time by 20% while maintaining high accuracy levels.

- Successfully identified and resolved a critical issue in a high-pressure pipeline, preventing potential downtime and significant financial losses.

- Implemented a proactive inspection program that reduced the number of unplanned repairs by 35%.

- Trained and mentored new inspectors, fostering a skilled and competent workforce.

- Prepared detailed inspection reports and provided recommendations for corrective actions.

- Collaborated with engineers and maintenance personnel to develop and implement inspection plans.

Frequently Asked Questions (FAQ’s) For Pipe Inspector

What is the primary responsibility of a Pipe Inspector?

The primary responsibility of a Pipe Inspector is to ensure the integrity and safety of piping systems through regular inspections and evaluations.

What qualifications are required to become a Pipe Inspector?

Typically, a Bachelor of Science in Mechanical Engineering or a related field, along with relevant certifications and training in inspection techniques, are required to become a Pipe Inspector.

What are the key skills required for a Pipe Inspector?

Key skills for a Pipe Inspector include knowledge of piping systems, inspection techniques, industry standards, and regulations, as well as strong analytical and problem-solving abilities.

What industries employ Pipe Inspectors?

Pipe Inspectors are employed in various industries, including oil and gas, chemical, power generation, and manufacturing.

What is the career growth potential for a Pipe Inspector?

With experience and additional certifications, Pipe Inspectors can advance to positions such as Senior Inspector, Inspection Manager, or Quality Assurance Manager.

What are the typical working conditions for a Pipe Inspector?

Pipe Inspectors typically work in industrial settings, which may involve working in confined spaces, at heights, or in hazardous environments.

What is the job outlook for Pipe Inspectors?

The job outlook for Pipe Inspectors is expected to be positive due to the increasing demand for qualified inspectors to ensure the safety and integrity of piping systems in various industries.

What professional organizations are available for Pipe Inspectors?

Professional organizations for Pipe Inspectors include the American Society of Nondestructive Testing (ASNT) and the National Association of Pipe Inspectors (NAPI).