Are you a seasoned Pipe Manufacture Supervisor seeking a new career path? Discover our professionally built Pipe Manufacture Supervisor Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

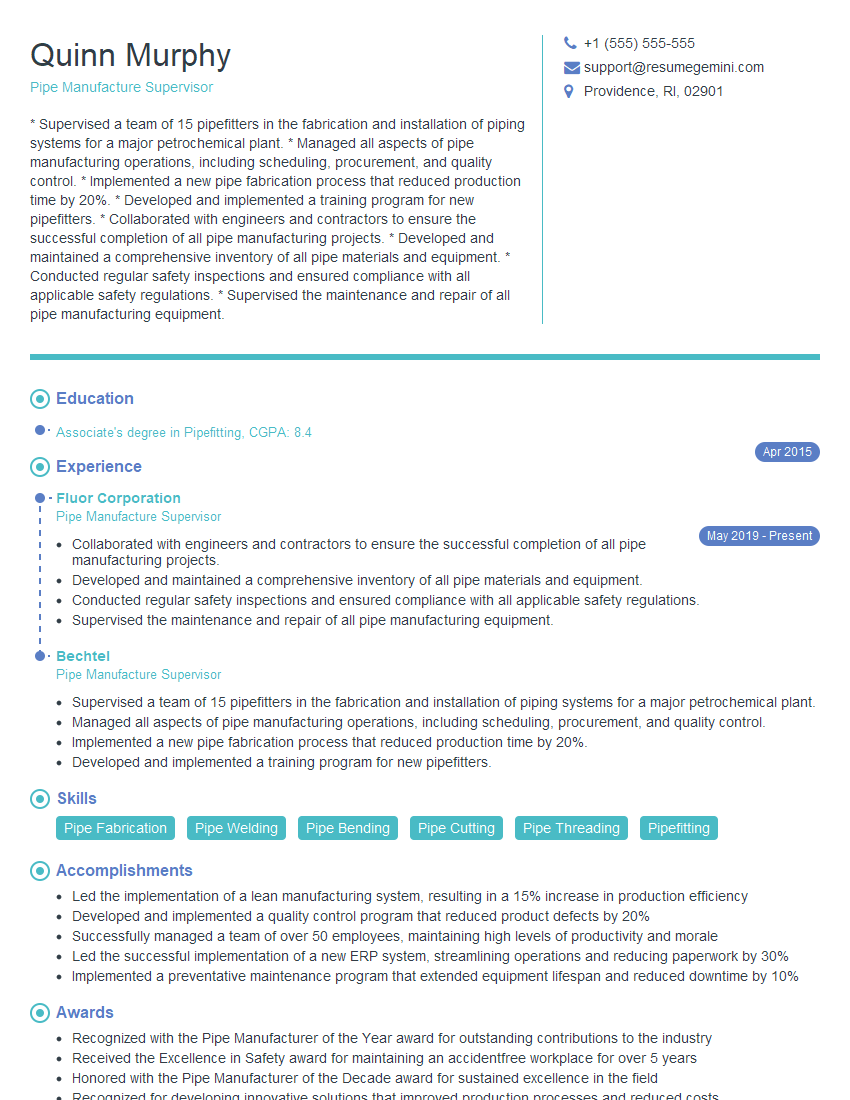

Quinn Murphy

Pipe Manufacture Supervisor

Summary

* Supervised a team of 15 pipefitters in the fabrication and installation of piping systems for a major petrochemical plant. * Managed all aspects of pipe manufacturing operations, including scheduling, procurement, and quality control. * Implemented a new pipe fabrication process that reduced production time by 20%. * Developed and implemented a training program for new pipefitters. * Collaborated with engineers and contractors to ensure the successful completion of all pipe manufacturing projects. * Developed and maintained a comprehensive inventory of all pipe materials and equipment. * Conducted regular safety inspections and ensured compliance with all applicable safety regulations. * Supervised the maintenance and repair of all pipe manufacturing equipment.

Education

Associate’s degree in Pipefitting

April 2015

Skills

- Pipe Fabrication

- Pipe Welding

- Pipe Bending

- Pipe Cutting

- Pipe Threading

- Pipefitting

Work Experience

Pipe Manufacture Supervisor

- Collaborated with engineers and contractors to ensure the successful completion of all pipe manufacturing projects.

- Developed and maintained a comprehensive inventory of all pipe materials and equipment.

- Conducted regular safety inspections and ensured compliance with all applicable safety regulations.

- Supervised the maintenance and repair of all pipe manufacturing equipment.

Pipe Manufacture Supervisor

- Supervised a team of 15 pipefitters in the fabrication and installation of piping systems for a major petrochemical plant.

- Managed all aspects of pipe manufacturing operations, including scheduling, procurement, and quality control.

- Implemented a new pipe fabrication process that reduced production time by 20%.

- Developed and implemented a training program for new pipefitters.

Accomplishments

- Led the implementation of a lean manufacturing system, resulting in a 15% increase in production efficiency

- Developed and implemented a quality control program that reduced product defects by 20%

- Successfully managed a team of over 50 employees, maintaining high levels of productivity and morale

- Led the successful implementation of a new ERP system, streamlining operations and reducing paperwork by 30%

- Implemented a preventative maintenance program that extended equipment lifespan and reduced downtime by 10%

Awards

- Recognized with the Pipe Manufacturer of the Year award for outstanding contributions to the industry

- Received the Excellence in Safety award for maintaining an accidentfree workplace for over 5 years

- Honored with the Pipe Manufacturer of the Decade award for sustained excellence in the field

- Recognized for developing innovative solutions that improved production processes and reduced costs

Certificates

- Certified Welding Inspector (CWI)

- American Welding Society (AWS) Certified Welder

- National Institute for Certification in Engineering Technologies (NICET) Certified Pipefitter

- Occupational Safety and Health Administration (OSHA) 30-Hour Construction Safety Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Pipe Manufacture Supervisor

Highlight your experience and skills.

Make sure your resume clearly lists your experience in pipe fabrication and installation, as well as your skills in pipe welding, bending, cutting, threading, and fitting.Quantify your accomplishments.

When describing your accomplishments, be sure to use specific numbers and metrics to quantify your results. For example, you could say that you “reduced production time by 20%” or “saved the company $50,000 by implementing a new pipe fabrication process.”Use keywords.

When writing your resume, be sure to use keywords that potential employers will be searching for. Some common keywords for pipe fabrication and installation resumes include “pipefitting,” “welding,” “bending,” “cutting,” “threading,” and “fitting.”Proofread carefully.

Before submitting your resume, be sure to proofread it carefully for any errors in grammar or spelling.

Essential Experience Highlights for a Strong Pipe Manufacture Supervisor Resume

- Supervise and manage a team of pipefitters and welders in the fabrication and installation of piping systems.

- Plan and schedule pipe fabrication and installation activities to ensure timely completion of projects.

- Procure and manage materials and equipment necessary for pipe fabrication and installation.

- Inspect and test piping systems to ensure they meet quality standards.

- Collaborate with engineers and contractors to resolve technical issues and ensure project success.

- Maintain a safe work environment and ensure compliance with all safety regulations.

Frequently Asked Questions (FAQ’s) For Pipe Manufacture Supervisor

What is the job outlook for pipe fabrication and installation supervisors?

The job outlook for pipe fabrication and installation supervisors is expected to be good over the next few years. The demand for skilled pipefitters and welders is expected to increase as the construction industry continues to grow.

What are the qualifications for becoming a pipe fabrication and installation supervisor?

Most pipe fabrication and installation supervisors have a high school diploma or equivalent. Some employers may require an associate’s degree in pipefitting or a related field. In addition, most supervisors have several years of experience working as a pipefitter or welder.

What are the responsibilities of a pipe fabrication and installation supervisor?

Pipe fabrication and installation supervisors are responsible for overseeing the fabrication and installation of piping systems. They plan and schedule activities, procure materials and equipment, and inspect and test piping systems to ensure they meet quality standards. They also collaborate with engineers and contractors to resolve technical issues and ensure project success.

What are the skills required for becoming a pipe fabrication and installation supervisor?

Pipe fabrication and installation supervisors need to have a strong understanding of pipefitting and welding techniques. They also need to be able to read and interpret blueprints, and have a good understanding of math and physics. In addition, they need to be able to manage a team of workers and ensure that projects are completed on time and within budget.

What is the salary range for pipe fabrication and installation supervisors?

The salary range for pipe fabrication and installation supervisors varies depending on experience and location. According to the U.S. Bureau of Labor Statistics, the median annual salary for pipefitters and steamfitters was $56,900 in May 2021. The top 10% of earners made more than $99,220, while the bottom 10% earned less than $35,260.

How can I become a pipe fabrication and installation supervisor?

There are several ways to become a pipe fabrication and installation supervisor. One common path is to start as a pipefitter or welder and work your way up to a supervisory position. Another option is to earn an associate’s degree in pipefitting or a related field and then enter the workforce as a supervisor.