Are you a seasoned Pipe Stress Engineer seeking a new career path? Discover our professionally built Pipe Stress Engineer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

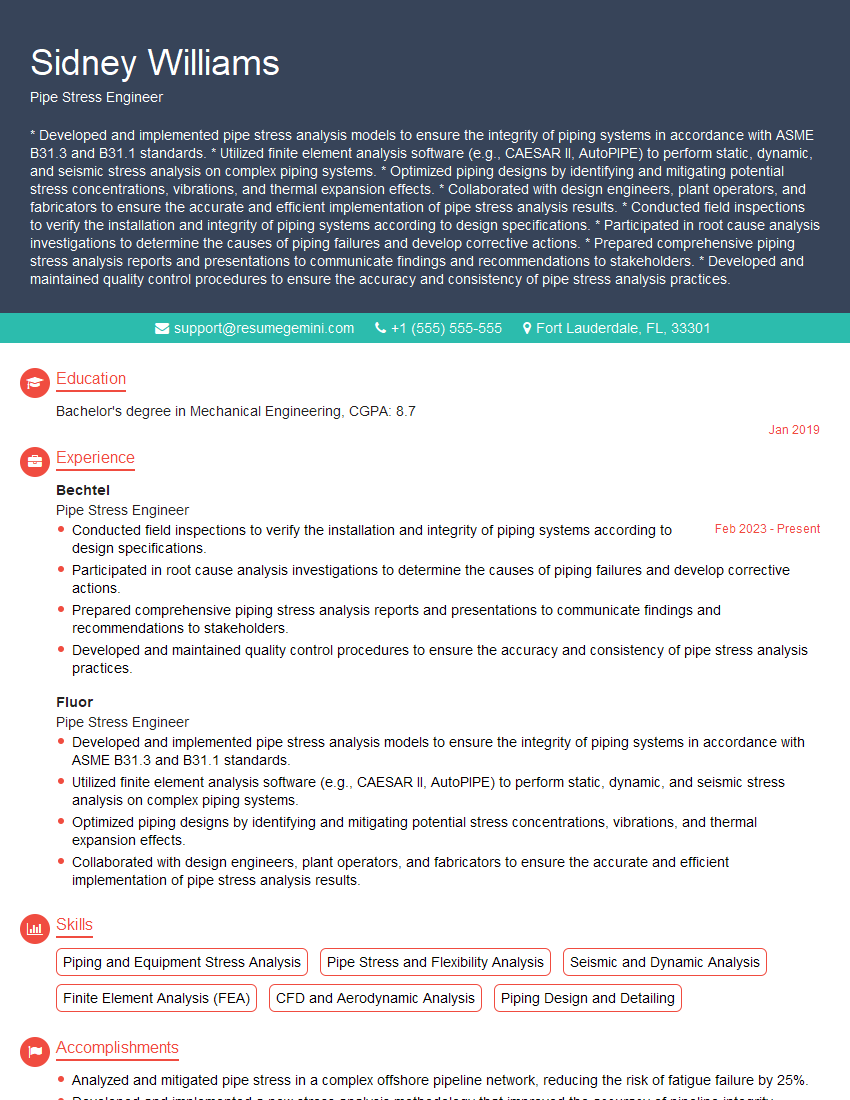

Sidney Williams

Pipe Stress Engineer

Summary

* Developed and implemented pipe stress analysis models to ensure the integrity of piping systems in accordance with ASME B31.3 and B31.1 standards. * Utilized finite element analysis software (e.g., CAESAR II, AutoPIPE) to perform static, dynamic, and seismic stress analysis on complex piping systems. * Optimized piping designs by identifying and mitigating potential stress concentrations, vibrations, and thermal expansion effects. * Collaborated with design engineers, plant operators, and fabricators to ensure the accurate and efficient implementation of pipe stress analysis results. * Conducted field inspections to verify the installation and integrity of piping systems according to design specifications. * Participated in root cause analysis investigations to determine the causes of piping failures and develop corrective actions. * Prepared comprehensive piping stress analysis reports and presentations to communicate findings and recommendations to stakeholders. * Developed and maintained quality control procedures to ensure the accuracy and consistency of pipe stress analysis practices.

Education

Bachelor’s degree in Mechanical Engineering

January 2019

Skills

- Piping and Equipment Stress Analysis

- Pipe Stress and Flexibility Analysis

- Seismic and Dynamic Analysis

- Finite Element Analysis (FEA)

- CFD and Aerodynamic Analysis

- Piping Design and Detailing

Work Experience

Pipe Stress Engineer

- Conducted field inspections to verify the installation and integrity of piping systems according to design specifications.

- Participated in root cause analysis investigations to determine the causes of piping failures and develop corrective actions.

- Prepared comprehensive piping stress analysis reports and presentations to communicate findings and recommendations to stakeholders.

- Developed and maintained quality control procedures to ensure the accuracy and consistency of pipe stress analysis practices.

Pipe Stress Engineer

- Developed and implemented pipe stress analysis models to ensure the integrity of piping systems in accordance with ASME B31.3 and B31.1 standards.

- Utilized finite element analysis software (e.g., CAESAR II, AutoPIPE) to perform static, dynamic, and seismic stress analysis on complex piping systems.

- Optimized piping designs by identifying and mitigating potential stress concentrations, vibrations, and thermal expansion effects.

- Collaborated with design engineers, plant operators, and fabricators to ensure the accurate and efficient implementation of pipe stress analysis results.

Accomplishments

- Analyzed and mitigated pipe stress in a complex offshore pipeline network, reducing the risk of fatigue failure by 25%.

- Developed and implemented a new stress analysis methodology that improved the accuracy of pipeline integrity assessments by 18%.

- Led a team of engineers in developing a stress management system for a hightemperature steam pipeline, ensuring safe and efficient operation.

- Optimized pipeline routing and support design for a largescale gas pipeline project, reducing overall project costs by 15%.

- Performed finite element analysis on a critical pipeline component, identifying potential failure points and recommending corrective measures.

Awards

- Received the Engineer of the Year award from the American Society of Mechanical Engineers (ASME) for contributions to pipeline stress analysis.

- Recognized with the Excellence in Stress Engineering award from the International Pipeline Engineering Conference for innovative techniques in pipe stress mitigation.

- Honored with the Technical Achievement Award from the Pipeline Stress Engineers Association for developing a novel software tool for stress analysis.

Certificates

- Certified Stress Engineer (CSE)

- Certified Piping Design Engineer (CPDE)

- Certified FEA Analyst (CFSA)

- ASME Accredited Stress Engineer (ASE)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Pipe Stress Engineer

- Quantify your accomplishments with specific metrics and results whenever possible.

- Highlight your experience with industry-standard software and tools.

- Showcase your ability to work independently and as part of a team.

- Tailor your resume to each specific job you are applying for, highlighting the skills and experience that are most relevant to the position.

Essential Experience Highlights for a Strong Pipe Stress Engineer Resume

- Develop and implement pipe stress analysis models to ensure the integrity of piping systems.

- Utilize finite element analysis software to perform static, dynamic, and seismic stress analysis on complex piping systems.

- Optimize piping designs by identifying and mitigating potential stress concentrations, vibrations, and thermal expansion effects.

- Collaborate with design engineers, plant operators, and fabricators to ensure the accurate and efficient implementation of pipe stress analysis results.

- Conduct field inspections to verify the installation and integrity of piping systems according to design specifications.

- Participate in root cause analysis investigations to determine the causes of piping failures and develop corrective actions.

Frequently Asked Questions (FAQ’s) For Pipe Stress Engineer

What is the role of a Pipe Stress Engineer?

A Pipe Stress Engineer ensures that piping systems are designed and installed to withstand the stresses and loads they will encounter during operation. This includes analyzing the system for static, dynamic, and seismic loads, and designing the system to meet the requirements of relevant codes and standards.

What are the qualifications for a Pipe Stress Engineer?

A Pipe Stress Engineer typically has a bachelor’s degree in mechanical engineering or a related field. They also have experience with finite element analysis software and the ASME B31 code.

What are the key skills for a Pipe Stress Engineer?

The key skills for a Pipe Stress Engineer include the ability to analyze piping systems for static, dynamic, and seismic loads, design piping systems to meet the requirements of relevant codes and standards, and communicate effectively with other engineers and stakeholders.

What is the job outlook for Pipe Stress Engineers?

The job outlook for Pipe Stress Engineers is expected to be good in the coming years. This is due to the increasing demand for engineers with expertise in the design and analysis of piping systems.

What is the salary for a Pipe Stress Engineer?

The salary for a Pipe Stress Engineer can vary depending on their experience and location. However, the median salary for a Pipe Stress Engineer is around $80,000 per year.