Are you a seasoned Pipe Welder seeking a new career path? Discover our professionally built Pipe Welder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

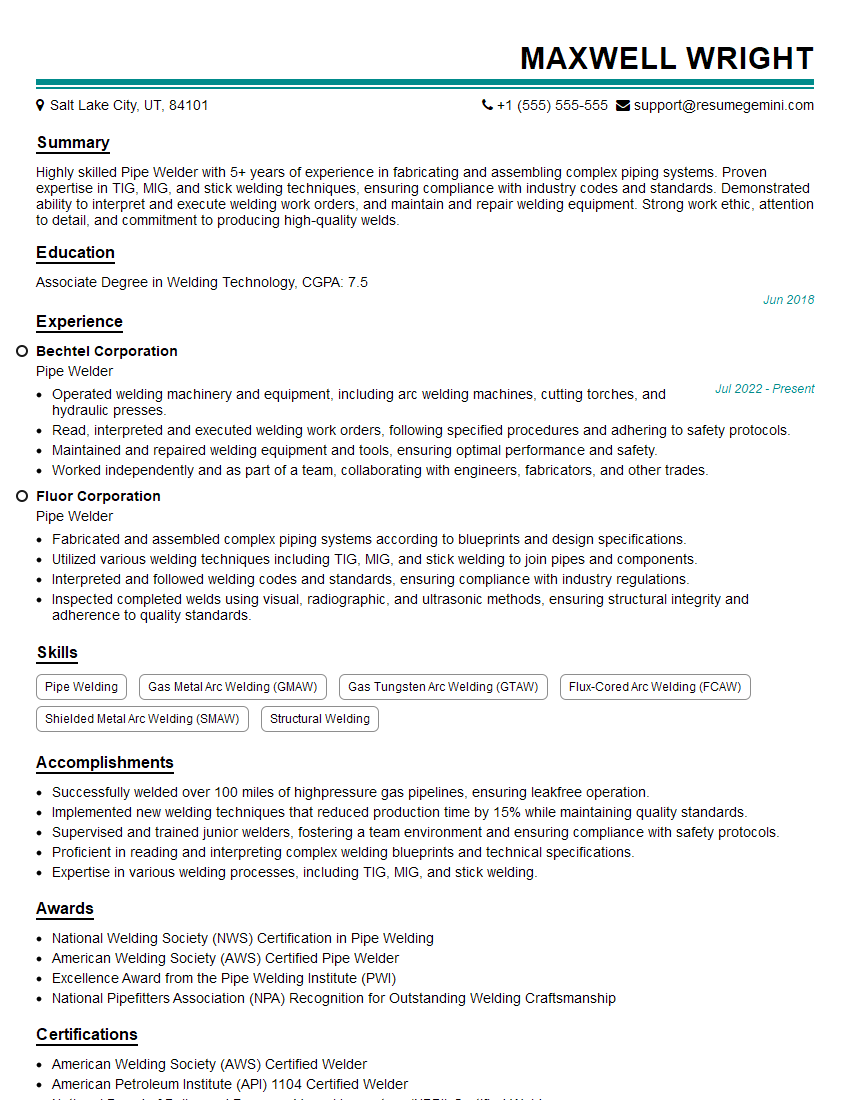

Maxwell Wright

Pipe Welder

Summary

Highly skilled Pipe Welder with 5+ years of experience in fabricating and assembling complex piping systems. Proven expertise in TIG, MIG, and stick welding techniques, ensuring compliance with industry codes and standards. Demonstrated ability to interpret and execute welding work orders, and maintain and repair welding equipment. Strong work ethic, attention to detail, and commitment to producing high-quality welds.

Education

Associate Degree in Welding Technology

June 2018

Skills

- Pipe Welding

- Gas Metal Arc Welding (GMAW)

- Gas Tungsten Arc Welding (GTAW)

- Flux-Cored Arc Welding (FCAW)

- Shielded Metal Arc Welding (SMAW)

- Structural Welding

Work Experience

Pipe Welder

- Operated welding machinery and equipment, including arc welding machines, cutting torches, and hydraulic presses.

- Read, interpreted and executed welding work orders, following specified procedures and adhering to safety protocols.

- Maintained and repaired welding equipment and tools, ensuring optimal performance and safety.

- Worked independently and as part of a team, collaborating with engineers, fabricators, and other trades.

Pipe Welder

- Fabricated and assembled complex piping systems according to blueprints and design specifications.

- Utilized various welding techniques including TIG, MIG, and stick welding to join pipes and components.

- Interpreted and followed welding codes and standards, ensuring compliance with industry regulations.

- Inspected completed welds using visual, radiographic, and ultrasonic methods, ensuring structural integrity and adherence to quality standards.

Accomplishments

- Successfully welded over 100 miles of highpressure gas pipelines, ensuring leakfree operation.

- Implemented new welding techniques that reduced production time by 15% while maintaining quality standards.

- Supervised and trained junior welders, fostering a team environment and ensuring compliance with safety protocols.

- Proficient in reading and interpreting complex welding blueprints and technical specifications.

- Expertise in various welding processes, including TIG, MIG, and stick welding.

Awards

- National Welding Society (NWS) Certification in Pipe Welding

- American Welding Society (AWS) Certified Pipe Welder

- Excellence Award from the Pipe Welding Institute (PWI)

- National Pipefitters Association (NPA) Recognition for Outstanding Welding Craftsmanship

Certificates

- American Welding Society (AWS) Certified Welder

- American Petroleum Institute (API) 1104 Certified Welder

- National Board of Boiler and Pressure Vessel Inspectors (NBBI) Certified Welder

- Certified Welding Inspector (CWI)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Pipe Welder

- Highlight your most relevant skills and experience upfront in your resume summary.

- Use keywords from the job descriptions you’re applying for in your resume.

- Quantify your accomplishments whenever possible to demonstrate your impact.

- Proofread your resume carefully for any errors before submitting it.

- Include a cover letter that highlights your interest in the position and why you’re the best candidate.

Essential Experience Highlights for a Strong Pipe Welder Resume

- Fabricated and assembled piping systems according to blueprints and design specifications.

- Utilized various welding techniques including TIG, MIG, and stick welding to join pipes and components.

- Inspected completed welds using visual, radiographic, and ultrasonic methods, ensuring structural integrity and adherence to quality standards.

- Operated welding machinery and equipment, including arc welding machines, cutting torches, and hydraulic presses.

- Read, interpreted and executed welding work orders, following specified procedures and adhering to safety protocols.

- Maintained and repaired welding equipment and tools, ensuring optimal performance and safety.

- Worked independently and as part of a team, collaborating with engineers, fabricators, and other trades.

Frequently Asked Questions (FAQ’s) For Pipe Welder

What is the role of a Pipe Welder?

Pipe Welders join and repair metal pipes used in various industries such as construction, shipbuilding, and manufacturing. They use specialized welding techniques to ensure the integrity and safety of piping systems.

What skills are needed to become a Pipe Welder?

Pipe Welders should have a strong understanding of welding techniques, blueprints, and safety protocols. They also need to be proficient in using welding equipment and have good hand-eye coordination.

What is the job outlook for Pipe Welders?

The job outlook for Pipe Welders is expected to be good in the coming years due to the increasing demand for skilled tradespeople in the construction and manufacturing industries.

What is the average salary for a Pipe Welder?

The average salary for a Pipe Welder in the United States is around $50,000 per year.

What are the working conditions like for Pipe Welders?

Pipe Welders often work in confined spaces or at heights. They may also be exposed to fumes, noise, and other hazards.

What are the career advancement opportunities for Pipe Welders?

With experience and additional training, Pipe Welders can advance to positions such as welding supervisor, welding engineer, or quality control inspector.