Are you a seasoned Piped Pocket Machine Operator seeking a new career path? Discover our professionally built Piped Pocket Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

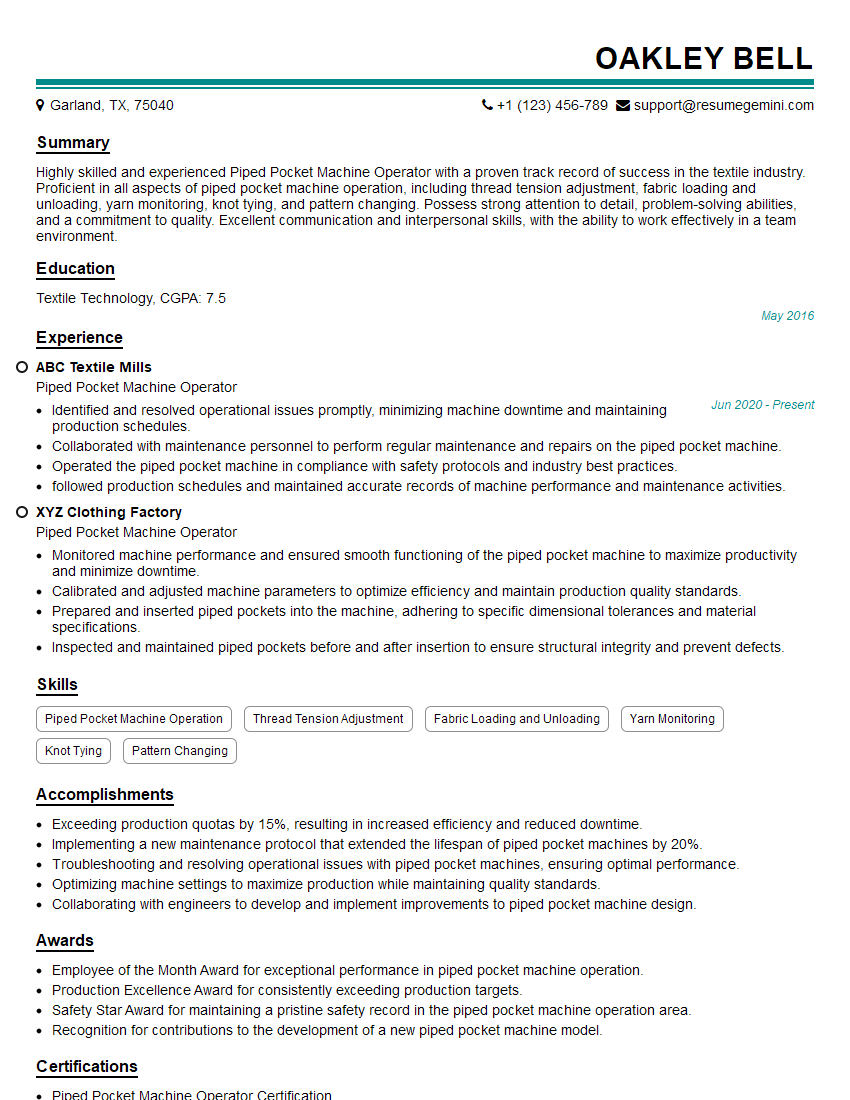

Oakley Bell

Piped Pocket Machine Operator

Summary

Highly skilled and experienced Piped Pocket Machine Operator with a proven track record of success in the textile industry. Proficient in all aspects of piped pocket machine operation, including thread tension adjustment, fabric loading and unloading, yarn monitoring, knot tying, and pattern changing. Possess strong attention to detail, problem-solving abilities, and a commitment to quality. Excellent communication and interpersonal skills, with the ability to work effectively in a team environment.

Education

Textile Technology

May 2016

Skills

- Piped Pocket Machine Operation

- Thread Tension Adjustment

- Fabric Loading and Unloading

- Yarn Monitoring

- Knot Tying

- Pattern Changing

Work Experience

Piped Pocket Machine Operator

- Identified and resolved operational issues promptly, minimizing machine downtime and maintaining production schedules.

- Collaborated with maintenance personnel to perform regular maintenance and repairs on the piped pocket machine.

- Operated the piped pocket machine in compliance with safety protocols and industry best practices.

- followed production schedules and maintained accurate records of machine performance and maintenance activities.

Piped Pocket Machine Operator

- Monitored machine performance and ensured smooth functioning of the piped pocket machine to maximize productivity and minimize downtime.

- Calibrated and adjusted machine parameters to optimize efficiency and maintain production quality standards.

- Prepared and inserted piped pockets into the machine, adhering to specific dimensional tolerances and material specifications.

- Inspected and maintained piped pockets before and after insertion to ensure structural integrity and prevent defects.

Accomplishments

- Exceeding production quotas by 15%, resulting in increased efficiency and reduced downtime.

- Implementing a new maintenance protocol that extended the lifespan of piped pocket machines by 20%.

- Troubleshooting and resolving operational issues with piped pocket machines, ensuring optimal performance.

- Optimizing machine settings to maximize production while maintaining quality standards.

- Collaborating with engineers to develop and implement improvements to piped pocket machine design.

Awards

- Employee of the Month Award for exceptional performance in piped pocket machine operation.

- Production Excellence Award for consistently exceeding production targets.

- Safety Star Award for maintaining a pristine safety record in the piped pocket machine operation area.

- Recognition for contributions to the development of a new piped pocket machine model.

Certificates

- Piped Pocket Machine Operator Certification

- OSHPD 30-hour Construction Safety and Health (OSHA)

- Basic Machine Maintenance Certificate

- Workplace First Aid and CPR Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Piped Pocket Machine Operator

- Highlight your experience and skills in your resume, emphasizing your proficiency in piped pocket machine operation and related tasks.

- Showcase your attention to detail and commitment to quality by providing specific examples of your work.

- Quantify your accomplishments whenever possible, such as the number of garments produced or the percentage of defects reduced.

- Tailor your resume to each job application, highlighting the skills and experience that are most relevant to the specific role.

Essential Experience Highlights for a Strong Piped Pocket Machine Operator Resume

- Operate piped pocket machines to produce high-quality garments and textiles.

- Adjust thread tension and fabric loading to ensure optimal stitch quality and prevent fabric damage.

- Monitor yarn supply and replace empty cones or tubes to maintain continuous production.

- Tie knots and mend broken threads to prevent defects and minimize downtime.

- Change patterns and set up machines for different garment styles.

- Maintain a clean and organized work area to ensure safety and efficiency.

- Collaborate with other team members to ensure smooth production flow.

Frequently Asked Questions (FAQ’s) For Piped Pocket Machine Operator

What is a piped pocket machine?

A piped pocket machine is a specialized sewing machine used to create piped pockets in garments and textiles. It uses a piping cord or welt to create a decorative and functional pocket.

What are the key skills required for a piped pocket machine operator?

Key skills for a piped pocket machine operator include thread tension adjustment, fabric loading and unloading, yarn monitoring, knot tying, pattern changing, attention to detail, problem-solving, and quality consciousness.

What are the career prospects for a piped pocket machine operator?

Piped pocket machine operators can advance to supervisory roles, such as production manager or quality control inspector. They may also specialize in specific types of garment production or work in different areas of the textile industry.

What are the typical working conditions for a piped pocket machine operator?

Piped pocket machine operators typically work in a factory or production environment. They may work standing or sitting for extended periods and may be exposed to noise and dust.

What are the educational requirements for a piped pocket machine operator?

While formal education is not always required, many piped pocket machine operators have a high school diploma or equivalent and may have received on-the-job training or attended vocational school.

What are the safety precautions that should be taken when operating a piped pocket machine?

Safety precautions include wearing appropriate clothing and safety gear, keeping hands and clothing away from moving parts, and following proper operating procedures to prevent accidents.

What are the common challenges faced by piped pocket machine operators?

Common challenges include maintaining consistent stitch quality, preventing fabric puckering or distortion, and troubleshooting mechanical issues to minimize downtime.